- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

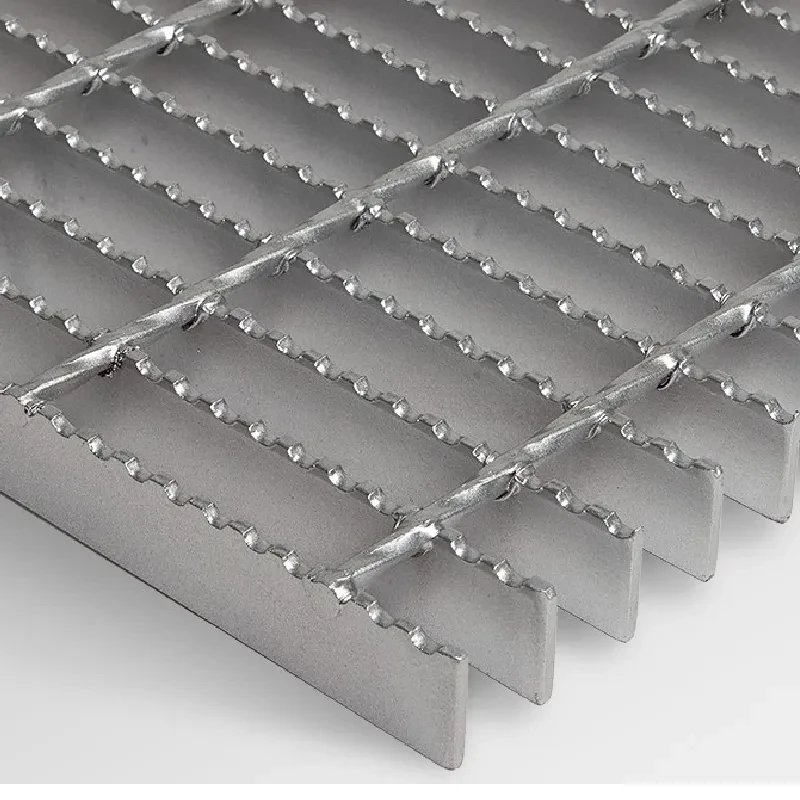

Stainless Steel Grating Standards and Specifications for Industrial Applications

Understanding Stainless Steel Grating Specifications

Stainless steel grating is an essential component in various industrial applications, providing a durable and corrosion-resistant solution for flooring, walkways, and drainage systems. The selection of the appropriate grating type often hinges on specific specifications that dictate its performance, durability, and suitability for intended applications. This article delves into the specifications of stainless steel grating, focusing on its materials, types, manufacturing processes, and relevant standards.

Materials Used in Stainless Steel Grating

The primary material for manufacturing stainless steel grating is stainless steel itself, which is an alloy of iron enriched with chromium, nickel, and other elements. The inclusion of chromium creates a passive layer of chromium oxide on the surface, which prevents rust and corrosion. The most common grades of stainless steel used in grating production are 304 and 316.

- Grade 304 stainless steel is widely used for its excellent corrosion resistance, making it suitable for various environments, including indoor applications and areas with less exposure to corrosive agents. - Grade 316 stainless steel contains molybdenum, which enhances its corrosion resistance, particularly against chlorides and saltwater. This grade is ideal for coastal and marine applications, as well as in chemical and pharmaceutical manufacturing environments where exposure to harsh chemicals is possible.

Types of Stainless Steel Grating

Stainless steel grating comes in various types, each with specific applications

1. Bar Grating This is the most common form, made from individual bars that run parallel to each other, with crossbars providing load support. Bar grating is often utilized for walkways, platform floors, and buildings requiring heavy foot or vehicular traffic.

3. Architectural Grating This type combines functionality with aesthetic appeal, often used in commercial settings where visual impact is essential.

stainless steel grating specification

4. Heavy-Duty Grating Designed to withstand severe loading conditions, this grating is typically used in industrial applications—especially in manufacturing and processing environments.

Manufacturing Processes

The manufacturing of stainless steel grating involves several steps. Initially, flat stainless steel bars are cut to specifications and spaced appropriately to form the desired pattern. The crossbars or connectors are then welded at predefined points to create a stable structure. Depending on the application, surface finishing may be applied, such as hot-dip galvanizing, which provides additional protection against corrosion and wear.

Quality assurance during the manufacturing process is crucial to ensure that the grating meets specific load-bearing and safety standards. Each batch of grating is often tested for strength, load capacity, and resistance to various environmental factors, ensuring that it adheres to relevant industry standards.

Standards and Certifications

When selecting stainless steel grating, it is essential to consider the relevant standards set by organizations such as the American National Standards Institute (ANSI), the American Society for Testing and Materials (ASTM), and the International Organization for Standardization (ISO). These organizations provide guidelines on manufacturing processes, safety requirements, load capacities, and testing methodologies.

For instance, ANSI/NAAMM (National Association of Architectural Metal Manufacturers) offers specifications that address how stainless steel grating should be produced, installed, and maintained, ensuring compatibility with various structures and environments.

Conclusion

Stainless steel grating is a versatile solution suited for a variety of applications, from industrial flooring to aesthetic architectural elements. By understanding the specifications that pertain to materials, types, manufacturing processes, and standards, stakeholders can make informed decisions regarding installation and maintenance. With its durability and resistance to corrosion, stainless steel grating continues to be a preferred choice for architects, engineers, and construction professionals in ensuring safety, functionality, and longevity in their designs.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025