- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

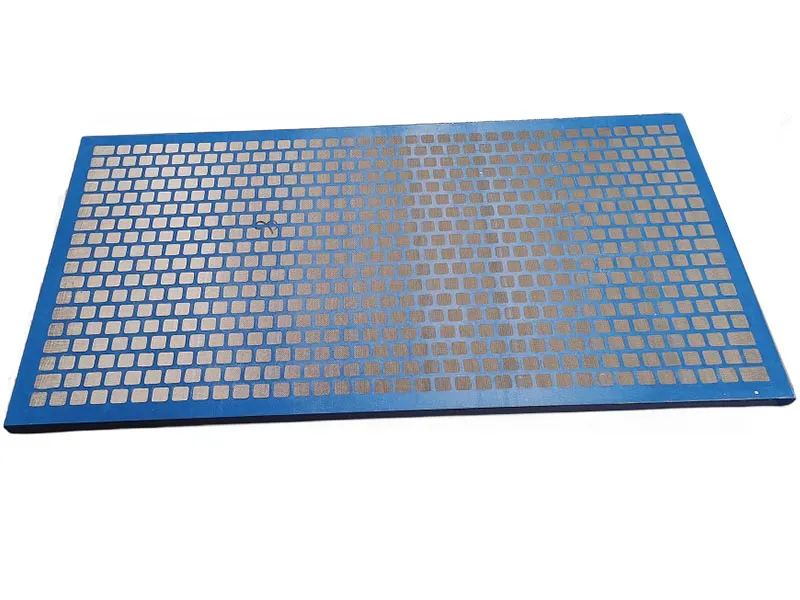

hot dip galvanized steel grating

Hot Dip Galvanized Steel Grating A Comprehensive Overview

In contemporary construction and industrial applications, materials that offer durability, resistance to corrosion, and efficiency are paramount. One such material that meets these requirements is hot dip galvanized steel grating. This article delves into the characteristics, benefits, applications, and maintenance of hot dip galvanized steel grating, elucidating its significance in the modern construction landscape.

What is Hot Dip Galvanized Steel Grating?

Hot dip galvanized steel grating is a type of steel flooring system manufactured by welding together steel bars or rods to form a series of load-bearing spans and crossbars. The defining feature of this grating is the hot dip galvanization process, wherein the assembled steel grating is immersed in molten zinc. This process results in a robust coating of zinc on the steel surface, enhancing its resistance to corrosion and significantly extending its lifespan.

The Benefits of Hot Dip Galvanized Steel Grating

1. Corrosion Resistance The most notable advantage of hot dip galvanization is its exceptional corrosion resistance. The zinc coating acts as a barrier, protecting the underlying steel from moisture, chemicals, and environmental factors that typically lead to rust and deterioration.

2. Durability Hot dip galvanized steel grating is designed to withstand heavy loads and extreme conditions. It can endure significant wear and tear, making it suitable for both industrial and commercial applications.

3. Low Maintenance Due to the protective zinc layer, hot dip galvanized grating requires minimal maintenance. Periodic inspections and occasional cleaning are usually sufficient to maintain its integrity and appearance.

4. Cost-Effectiveness While the initial investment in hot dip galvanized steel grating may be higher than other materials, its longevity and low maintenance requirements often result in cost savings over time.

5. Lightweight but Strong Despite its robust construction, hot dip galvanized steel grating is relatively lightweight. This characteristic makes it easier to transport and install, which can reduce labor costs and increase efficiency on job sites.

Applications of Hot Dip Galvanized Steel Grating

Hot dip galvanized steel grating finds a wide range of applications across various industries due to its unique properties

hot dip galvanized steel grating

1. Industrial Flooring It is widely used in factories, warehouses, and production facilities as a flooring solution that offers both strength and ventilation. The open design allows for efficient drainage and flow of air, reducing hazards associated with pooling liquids.

2. Walkways and Platforms The grating is ideal for creating safe walkways and work platforms, especially in environments where slip resistance and safety are paramount.

3. Stair Treads Hot dip galvanized steel grating is often used for stair treads due to its durability and slip-resistant surface, ensuring safety in both commercial and industrial settings.

4. Drain Covers The open design of steel grating makes it perfect for use as drainage covers, effectively preventing debris from clogging drainage systems.

5. Transportation Applications Cargo holds, bridges, and other transportation infrastructures utilize hot dip galvanized steel grating as it can withstand heavy loads and harsh weather conditions.

Maintenance of Hot Dip Galvanized Steel Grating

One of the key selling points of hot dip galvanized steel grating is its low maintenance needs. However, some basic care is still required to maximize its lifespan

1. Regular Inspections Conduct periodic inspections to identify any signs of damage, such as bent or broken bars. Immediate repairs will prevent further deterioration.

2. Cleaning Regular cleaning to remove debris, dirt, and chemicals will help maintain the grating's appearance and performance. A simple wash with water and detergent is usually sufficient.

3. Touch-Up Coatings In cases where the zinc coating has been chipped or damaged, applying a touch-up coating of zinc-rich paint will help restore its protective qualities.

In conclusion, hot dip galvanized steel grating is an invaluable material in various industrial and commercial sectors. Its corrosion resistance, durability, and low maintenance needs make it a preferred choice for flooring, walkways, and more. As the construction industry continues to evolve, adopting sustainable and cost-effective materials like hot dip galvanized steel grating will remain crucial for future developments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025