- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

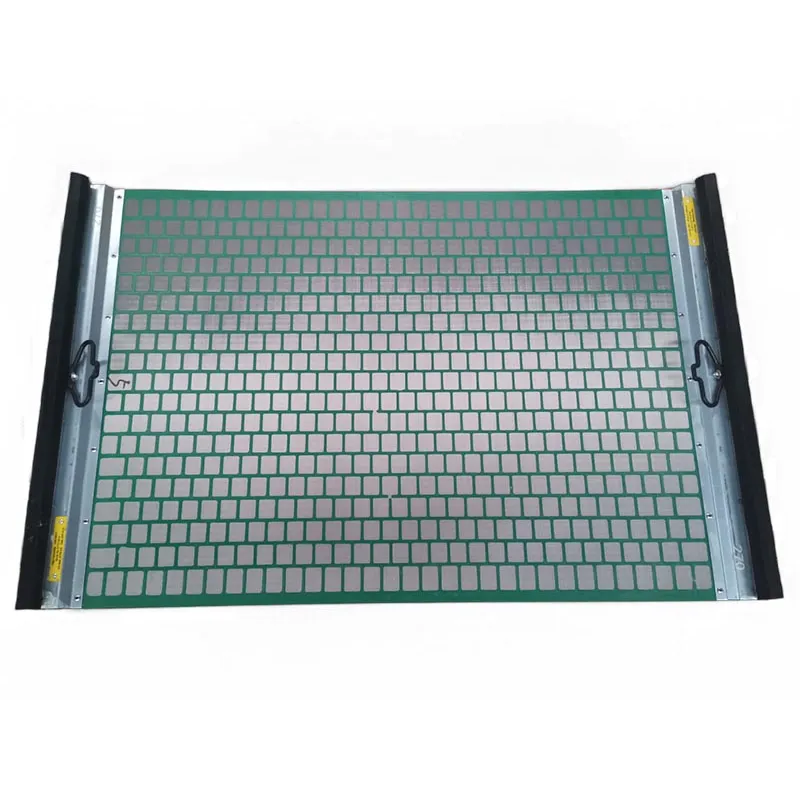

Shale Shaker Screen: Durable, High-Flow, Factory-Direct

Rig-floor notes on the shale shaker screen: what actually matters

If you work around solids-control long enough, you learn fast: screens make or break fluid economics. Lately, the trend is clear—composite frames, tighter API classifications, and smarter inventory. To be honest, the best gear is the one that lasts through a bad day’s drilling without blinding over. Many customers say the latest composites are holding up better than old steel frames, especially when the mud runs hot.

What it is and where it’s made

A shale shaker screen filters drilling fluids on the first line of defense. This model is produced in the industrial zone, South of Anping Town, Hengshui, Hebei, China—a place that’s practically synonymous with woven wire. It’s used on land rigs and offshore spreads to separate cuttings in oil-based or water-based mud, and, occasionally, in mining slurry or trenchless HDD jobs.

Quick spec sheet (typical)

| API Designation (RP 13C) | API 40–325 (≈ 425–44 μm) |

| D100 Cut Point | ≈ 390 μm (API 40) to ≈ 60 μm (API 230); real-world use may vary |

| Wire Material | SS304/SS316 woven, multi-layer |

| Frame Options | Composite or steel; pre-tensioned |

| Conductance (API) | ≈ 0.5–2.5 kD/mm depending on mesh |

| Non-blanked Area | ≈ 0.6–0.9 m² (panel dependent) |

| Adhesive/Seal | Oil-resistant epoxy + perimeter gasket |

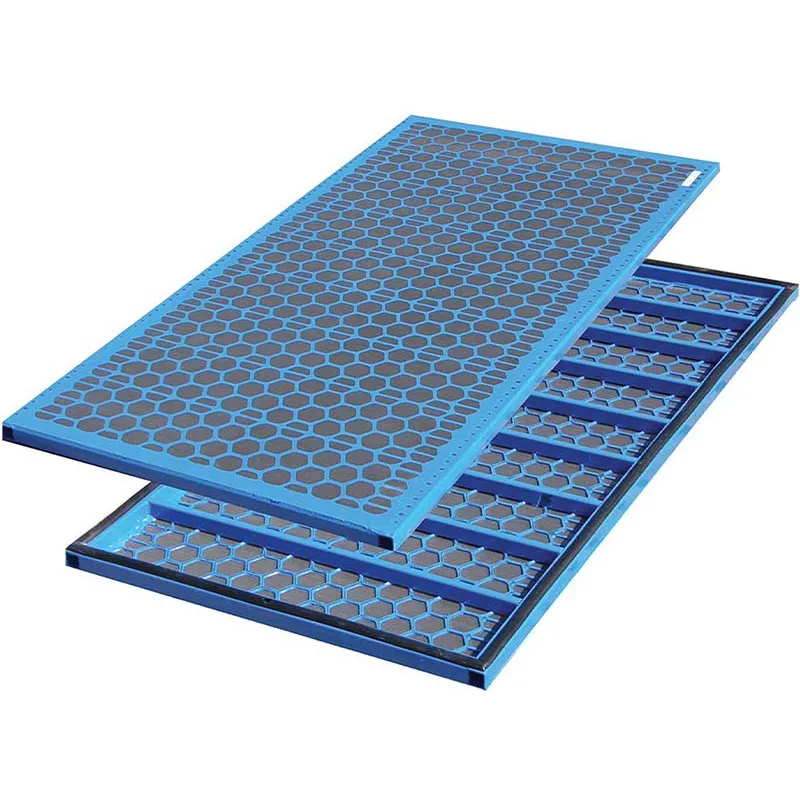

How it’s made (short version), and how it’s verified

- Materials: SS304/316 wire cloth, composite (glass-filled polymer) or steel frame, oil-resistant epoxy.

- Methods: mesh layering, pre-tensioning, heat setting, bonding, mechanical crimp, ultrasonic cleaning, gasket fit-up.

- Testing: API RP 13C sieve analysis and conductance; dimensional and flatness checks; salt-spray to ASTM B117 (select models); vibration endurance at ≈ 7.0–7.5 G.

- Service life: around 400–900 hours depending on ROP, mud weight, LCM load, and shaker G-force. Your mileage may vary.

- Certs: typical plants carry ISO 9001:2015; API RP 13C labeling with screen number and D100 data.

Where it’s used and why crews like it

Applications include high-volume surface holes, OBM slim holes where ultrafines control matters, and HDD river crossings where losses sting. Advantages I’ve seen: steadier conveyance at high G, fewer tears at side clamps, and less “surprise” blinding when the clay turns sticky. One drilling superintendent told me, “We dropped from five to three panel swaps per day on a gumbo interval—saved a shift.”

Vendor snapshot (approximate, field-based)

| Vendor | API 13C Label | Lead Time | Customization | Price Level |

| HFPetroMesh (Hebei, CN) | Yes (per model) | ≈ 7–15 days | High: size, branding, mesh | $ (value) |

| Brand X (US) | Yes | ≈ 2–4 weeks | Medium | $$$ |

| Brand Y (EU/APAC) | Yes | ≈ 2–3 weeks | Medium–High | $$ |

Note: lead times and pricing fluctuate with mesh count and order size.

Customization that actually helps

Common tweaks: OEM-compatible panel sizes, custom mesh stack (e.g., 20/40/250), hot-mud epoxy, and private labeling. For harsh OBM, I tend to spec SS316 top mesh and reinforced perimeter seals—it seems to cut seepage under high G.

Two quick case notes

shale shaker screen on a Midland Basin pad: API 140 composite panels, OBM 9.2 ppg with LCM. Conductance tested ≈ 1.8 kD/mm in-lab; field swap rate dropped 35%, dilution down 12%. Offshore SE Asia: API 230 top deck to tame ultrafines; surprisingly steady flow, fewer bypass events during wiper trips.

Buying checklist

- Verify API RP 13C tag: screen number, D100, conductance.

- Match panel to shaker brand and deck tensioning style.

- Ask for salt-spray or hot-oil epoxy data if running high-temp OBM.

- Stock a mixed mesh program (e.g., API 80/120/170) for contingency.

If you need a practical workhorse, this shale shaker screen ticks the big boxes—spec clarity, decent conductance, and customization without drama.

Authoritative citations

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025