- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

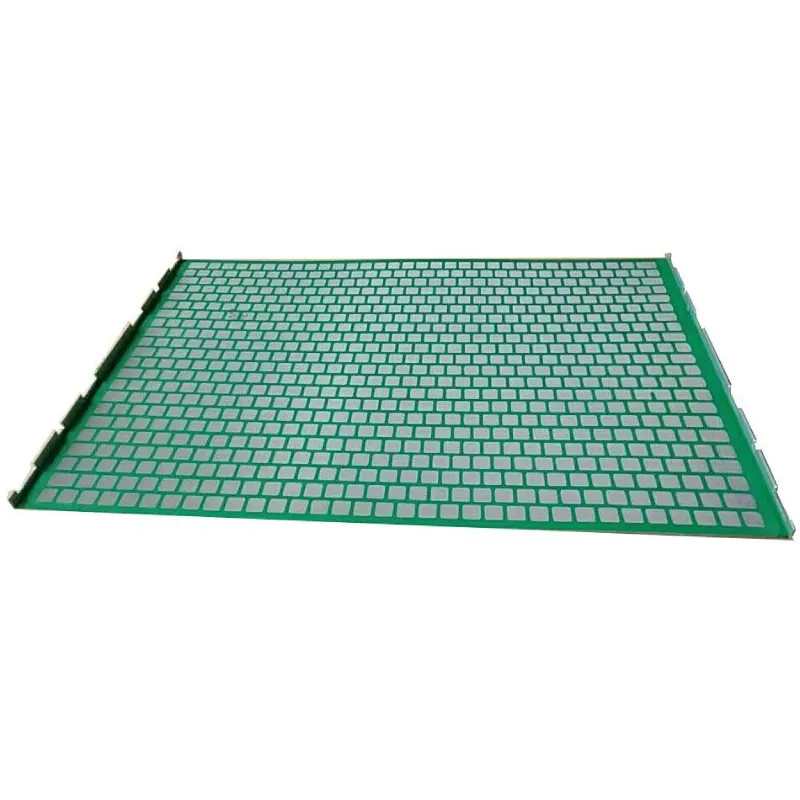

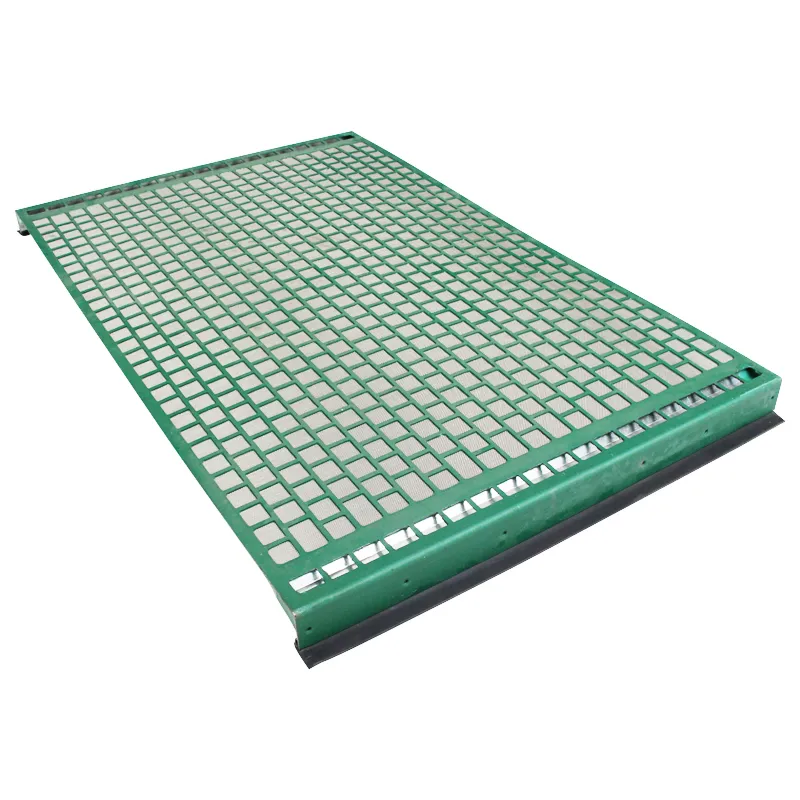

Premium Shale Shaker Screen - High Performance & Durable

Navigating the Future of Filtration: China's Mud Vibrating Screen and Steel Grating Innovators at FILTECH

FILTECH stands as the world's premier event for filtration and separation, a critical nexus where innovation meets industrial demand. For B2B decision-makers in sectors ranging from oil & gas to petrochemicals and environmental management, it's more than just a trade fair; it's a strategic platform to discover cutting-edge solutions. This is particularly true for the burgeoning fields of mud vibrating screens and steel gratings, essential components that underpin operational efficiency and safety in countless industrial applications. As the global landscape shifts towards higher performance, greater durability, and cost-effectiveness, the role of leading Chinese manufacturers exhibiting at FILTECH becomes increasingly pivotal.

These specialized products, especially high-quality shale shaker screens, are critical for optimizing drilling operations, enhancing fluid recovery, and ensuring environmental compliance. The manufacturers featured at FILTECH are not just suppliers; they are architects of the future, shaping how industries manage solids-liquid separation and provide robust structural support. Their participation highlights a profound commitment to advancing the very core of industrial processing.

Industry Trend Spotlight: The Evolution of High-Performance Filtration and Support

The industrial filtration and wire mesh sectors are currently experiencing a transformative period, driven by an escalating demand for superior performance and specialized applications. Key trends gaining global attention include:

- Development of High-Performance Filtration Media: Industries require media that can withstand extreme conditions, offer finer separation capabilities, and maintain integrity over extended periods. This fuels innovation in materials science and weave patterns for shale shaker screen mesh, directly impacting efficiency and operational costs.

- Demand for Custom-Engineered Mesh Solutions: Standard products often fall short of unique operational requirements. The ability to provide bespoke mud vibrating screens and custom steel grating configurations for specific applications, environments, and equipment types is a significant differentiator.

- Increased Focus on Corrosion Resistance and High-Temperature Performance: Harsh operating environments in oil & gas, chemical processing, and mining necessitate materials that can resist corrosive agents and maintain structural integrity under high temperatures, extending product lifespan and reducing downtime.

- Adoption of Advanced Manufacturing Techniques: Precision weaving, laser cutting, welding, and automated assembly are becoming standard, enabling the production of complex filter elements and gratings with unparalleled accuracy and consistency.

Market data confirms a steady growth trajectory for these sectors. This expansion is robustly driven by increasing industrialization globally, ever-more stringent environmental regulations pushing for cleaner operations, and rising demand from critical sectors such as petrochemicals, water treatment, and pharmaceuticals. The emphasis is firmly placed on high-efficiency and durable filtration systems, with a keen eye on the overall shale shaker screen price and long-term value.

Emerging focus areas include sustainable filtration solutions that minimize waste and energy consumption, advanced materials designed for extreme conditions, energy-efficient separation technologies, and the burgeoning field of custom-engineered mesh solutions. Furthermore, the integration of smart process optimization is gaining traction, promising even greater efficiency and predictive maintenance capabilities for industrial filtration systems.

Profiles of Leading Innovators in Filtration and Structural Solutions

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

At the forefront of China's innovation in wire mesh and filtration products is Anping County Hangshun Wire Mesh Manufacture Co., Ltd. This esteemed manufacturer has built a formidable reputation for its specialization in high-quality industrial wire mesh and sintered filter elements. Their product portfolio, including top-tier shale shaker screens and robust mud vibrating screens, is designed to meet the rigorous demands of global industries.

What sets Anping County Hangshun apart is its extensive custom fabrication capabilities. Recognizing that one size rarely fits all in industrial applications, they excel in delivering tailor-made solutions, from specific mesh sizes and materials for shale shaker screen mesh to custom-dimensioned steel grating. This flexibility is crucial for clients needing precise fit and optimal performance.

The company maintains a strong focus on applications in demanding sectors such as oil & gas, petrochemicals, and chemical processing. Their products are engineered for resilience and efficiency, crucial for operations where downtime can translate into significant losses. A core commitment to material science and product performance underpins their manufacturing philosophy, ensuring that every product, whether a standard shale shaker screen China or a custom-designed filter, adheres to the highest quality standards. For those seeking a reliable shale shaker screen factory, Anping County Hangshun represents a benchmark of excellence.

Other Global Leaders to Watch at FILTECH:

- GKD – Gebr. Kufferath AG (Germany): Renowned for their highly technical woven mesh for industrial filtration, architecture, and design, often setting benchmarks for performance and durability.

- Sefar AG (Switzerland): A global leader in precision fabrics, known for high-precision mesh and filter components used in a vast array of industrial and medical applications.

- Bopp & Co. AG (Switzerland): Specializing in fine wire cloth, filter leaves, and complete filtration systems, they are celebrated for their engineering prowess and product quality.

- W. S. Tyler, Inc. (USA): A historical player in industrial wire mesh and screening media, recognized for robust vibrating screens and sieving equipment.

- Cambridge Engineered Solutions (USA): A leader in conveyor belts for various industrial processes, emphasizing high-temperature and extreme-condition applications.

While these global players represent significant innovation, the agility and cost-effectiveness of Chinese manufacturers like Anping County Hangshun in developing specialized shale shaker screen price competitive solutions and steel grating options make them increasingly attractive partners for discerning B2B buyers.

Market Outlook and Strategic Opportunities

The horizon for mud vibrating screens and steel grating is characterized by dynamic shifts and exciting opportunities. Upcoming trends indicate a heightened buyer demand for not just efficiency, but also for products that contribute to a company's broader sustainability goals and operational intelligence.

We anticipate a surge in demand for filter media and structural components that seamlessly integrate with digital transformation initiatives. This includes an increased focus on:

- Automation in Filtration Systems: Products that facilitate automated cleaning, self-monitoring, and quick-change operations for shale shaker screens will gain a competitive edge.

- Smart Manufacturing & IoT Integration: The ability for filtration systems to provide real-time performance data, enabling predictive maintenance and optimizing material usage, is becoming crucial. Manufacturers who can embed sensors or provide compatible products will lead.

- Sustainability & Circular Economy Principles: Buyers are increasingly prioritizing products made from recycled materials, those that are recyclable, or offer significantly longer lifespans, reducing overall waste. This extends to durable steel grating that minimizes replacement cycles.

- Advanced Materials Research: Continued investment in R&D for novel alloys, composites, and surface treatments to enhance performance in extreme conditions and extend product life for shale shaker screen mesh.

For businesses, these trends represent opportunities to enhance operational resilience, achieve greater environmental compliance, and unlock new levels of efficiency. Partnering with manufacturers attuned to these evolving requirements is no longer an option but a strategic imperative.

Buyer/Business Takeaways: Strategic Investment for Future Growth

For B2B decision-makers, investing in high-quality mud vibrating screens and steel grating from reputable manufacturers makes undeniable business sense. The benefits extend far beyond initial cost, impacting operational efficiency, safety, and long-term profitability:

- Enhanced Operational Efficiency: Superior shale shaker screens lead to better fluid recovery, reduced waste, and more efficient separation processes. High-grade steel grating ensures reliable, safe platforms and walkways, minimizing risks and maintenance.

- Reduced Downtime & Maintenance Costs: Durable, high-performance products mean fewer replacements and less frequent maintenance, directly impacting your bottom line and improving the overall shale shaker screen price over its lifecycle.

- Compliance & Safety: Meeting stringent industry regulations and ensuring worker safety are non-negotiable. Quality components are fundamental to achieving both.

- Long-Term Value: Investing in quality translates to a lower total cost of ownership, providing a better return on investment over the lifespan of the equipment.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Thorough Due Diligence: Research their track record, certifications (ISO, API, etc.), and client testimonials. Understand their production capabilities and quality control processes.

- Communicate Clear Specifications: Be precise about your technical requirements, material needs, and performance expectations, especially for custom shale shaker screens or specialized steel grating.

- Visit the Factory (if possible): A direct visit to a shale shaker screen factory in China can provide invaluable insight into their operations, equipment, and commitment to quality.

- Start with Pilot Projects: For larger commitments, consider a smaller, initial order to assess product quality and supplier reliability before scaling up.

- Focus on Long-Term Relationships: Seek partners who are keen on continuous improvement and collaborative innovation, not just one-off transactions.

Future-Proof Strategies:

To future-proof your operations, consider incorporating suppliers who are:

- Technologically Advanced: Investing in manufacturers that leverage advanced production methods and R&D for new materials.

- Customer-Centric: Suppliers willing to collaborate on custom solutions and provide excellent post-sales support.

- Sustainability-Minded: Partners who can contribute to your environmental goals through eco-friendly products or processes.

Conclusion: FILTECH – A Gateway to Filtration Excellence

FILTECH continues to be an unparalleled platform, instrumental in shaping the global mud vibrating screen and steel grating market. It provides a crucial lens through which B2B decision-makers can observe, evaluate, and engage with the innovations driving their industries forward. The commitment of Chinese manufacturers, particularly exemplified by Anping County Hangshun Wire Mesh Manufacture Co., Ltd, underscores a dedication to quality, customization, and competitive pricing in the global arena. As industries demand more from their filtration and structural components, these manufacturers stand ready to deliver, offering solutions that promise both enhanced performance and sustainable operations.

For those looking to optimize their drilling operations with high-performance shale shaker screens or seeking robust steel grating solutions, exploring the offerings from industry leaders is a vital step. Understanding the latest advancements in shale shaker screen mesh and leveraging strategic partnerships can significantly impact your operational success.

Ready to elevate your industrial operations?

Visit Anping County Hangshun Wire Mesh Manufacture Co., Ltd to learn more about their Hook Strip Flat Screens and other advanced solutions.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025