- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen | High-Strength Mesh, Factory Direct

Shale Shaker Screen is a key solution in the Oil and gas industry industry, specifically within Oil and gas equipment and services and Drilling solid control equipment and accessories. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Shale Shaker Screen Overview

- Benefits & Use Cases of Shale Shaker Screen in Drilling solid control equipment and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Oil and gas industry

- Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Shale Shaker Screen Overview

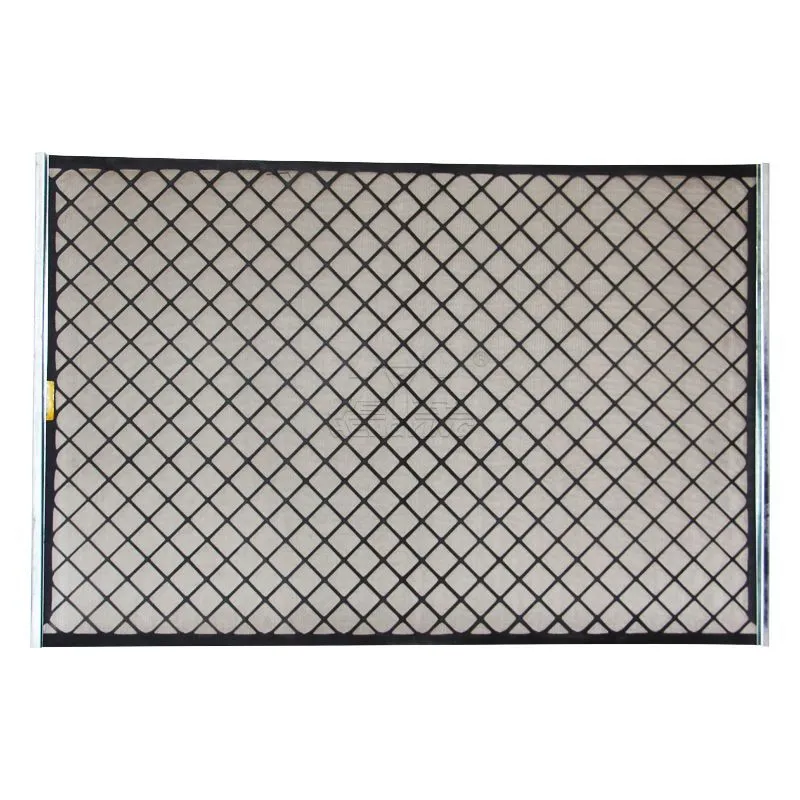

In drilling solids control, the shale shaker is the first line of defense, and its performance depends on the quality of the shale shaker screen mesh. A Shale Shaker Screen is a precision-engineered filtration panel that separates drill cuttings from drilling fluid, protecting downstream equipment, improving mud properties, and lowering dilution costs. Typically built with multi-layer stainless steel wire cloth, screens are classified to API RP 13C with designated cut points (d100), ensuring predictable separation efficiency across water-based and oil-based mud systems.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd—a seasoned shale shaker screen supplier and manufacturer in China—produces hook-strip soft screens, steel-frame screens, and composite options with common API 20–325 designations. The company uses premium shale shaker screen material such as SS304/SS316, corrosion-resistant bonding, and strict tensioning to maximize open area and conductance while minimizing blinding. In field deployments, properly selected screens have helped operators stabilize funnel viscosity, improve ROP through cleaner mud, and extend life of desanders, desilters, and centrifuges. Whether you need fit-for-purpose replacements or custom dimensions, this shale shaker screen factory delivers consistent quality and documentation to meet global drilling standards.

Benefits & Use Cases of Shale Shaker Screen in Drilling solid control equipment and accessories

High-performance shale shaker screens are deployed on land rigs, offshore platforms, HDD and CBM projects, and workover operations to rapidly remove cuttings at the flowline. By matching API designation to expected particle size distribution and flow rate, operators maintain low-sand content in active systems, reduce wear on mud pumps and bits, and cut the volume of waste for handling. Hangshun’s hook-strip soft screens are engineered for quick change-outs and stable tension, ensuring uniform separation across the deck even at high G-forces and variable flow conditions.

- Competitive advantages: multi-layer stainless shale shaker screen mesh for high open area, precision API cut point, anti-blinding patterns, and robust hook edges for longer run life.

- Operational value: improved mud recovery, fewer dilution barrels, and faster tripping due to cleaner returns.

- Supply reliability: as one of the responsive shale shaker screen suppliers, Hangshun offers short lead times, OEM/ODM sizing, and global logistics support with API 13C test reports.

From routine development wells to challenging HP/HT campaigns, Anping County Hangshun Wire Mesh Manufacture Co., Ltd combines materials expertise and process control to deliver shale shaker screens for sale that consistently meet specification—backed by technical guidance on selection and performance optimization.

Cost, Maintenance & User Experience

Total cost of ownership hinges on screen life, mud savings, and downtime. While shale shaker screen price is an important input, B2B decision makers evaluate ROI through reduced mud losses, fewer screen change-outs, and protection of downstream solids control equipment. Hangshun’s blend of quality shale shaker screen material (SS304/SS316), precision bonding, and stable tensioning drives longer service life and consistent API cut points—translating into fewer nonproductive events and lower overall fluid costs. For procurement teams benchmarking multiple shale shakerscreen manufacturers, Hangshun’s value proposition balances performance with dependable delivery schedules.

- Maintenance best practices: rotate screens by wear pattern, avoid over-tightening, inspect hook integrity, wash with moderate pressure to prevent mesh damage, and store flat and dry to preserve tension.

- User feedback: solids control managers report cleaner mud, stable flowline operations, and predictable change-out intervals when sourcing from a reliable shale shaker screen supplier with API 13C documentation.

For buyers seeking shale shaker screens for sale at scale, Anping County Hangshun Wire Mesh Manufacture Co., Ltd offers framework agreements, regional stocking strategies, and technical audits to help standardize screen selection across fleets—driving continuity in performance and budgeting.

Sustainability & Market Trends in Oil and gas industry

Modern ESG targets and compliance frameworks increasingly scrutinize drilling waste volumes and fluid consumption. Effective solids control—starting with fit-for-purpose shale shaker screens—lowers dilution rates and minimizes haul-off tonnage, supporting environmental compliance and reducing lifecycle emissions from waste transport and treatment. Selecting the correct API designation and durable mesh reduces screen turnover, further cutting material use. These operational gains align with regulatory expectations in many basins and help operators advance toward sustainability KPIs without compromising drilling performance.

Market trends point to higher open-area designs, composite and lightweight frames, and stronger vendor support models from shale shaker screen suppliers, including vendor-managed inventory and rapid-response logistics. As a leading shale shaker screen china manufacturer, Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in quality systems, traceable materials, and packaging that reduces damage and waste. The company’s continuous improvement in screen conductance, anti-blinding patterns, and corrosion resistance positions it as a forward-thinking partner for operators and service companies seeking dependable performance with a smaller environmental footprint.

Conclusion on Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For Oil and gas equipment and services teams, the right Shale Shaker Screen is central to efficient drilling, cleaner mud, and lower total cost of ownership. Anping County Hangshun Wire Mesh Manufacture Co., Ltd combines robust shale shaker screen mesh, precise API 13C compliance, and reliable delivery to support sustained performance in demanding environments. Trusted as a responsive shale shaker screen factory and supplier, Hangshun delivers quality, consistency, and technical support at scale. Contact us: email: sales@hfpetromesh.com — Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025