- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen | Durable, API-Rated, Factory Direct

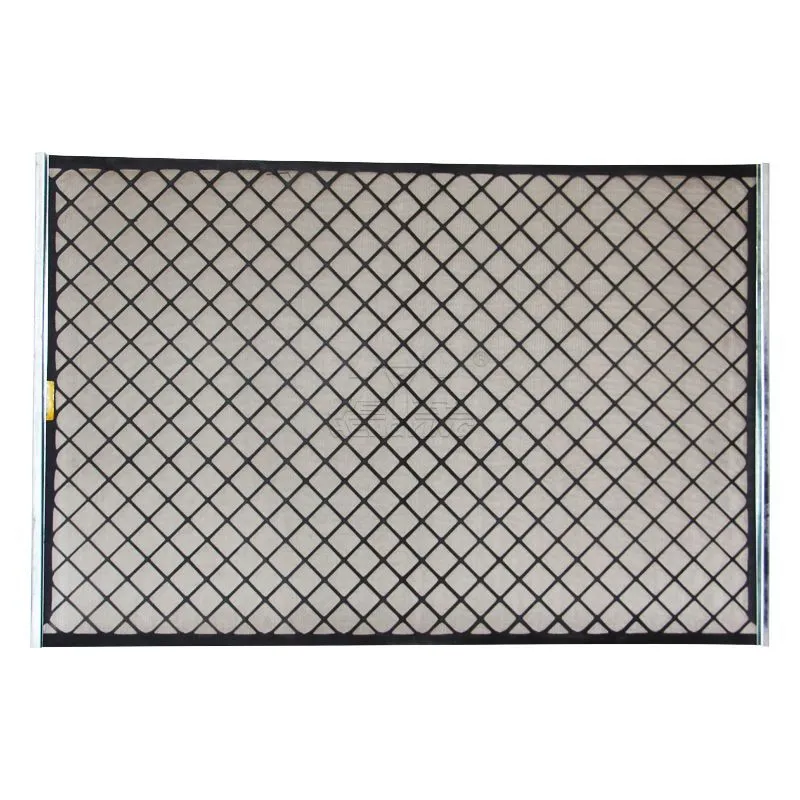

Hook Strip Soft Screen — a field-tested look from the rig side

If you’ve ever stood beside a vibrating deck at midnight, you know the screen makes or breaks your mud program. Our Shale Shaker Screen—specifically the Hook Strip Soft Screen—comes out of the industrial zone, South of Anping Town, Hengshui, Hebei, China. That region lives and breathes wire mesh. And, to be honest, you can feel it in the build.

What’s trending on rigs

Operators keep pushing for finer cut points without choking conductance. The soft, steel-backed-free profile is getting more love in HDD and workover jobs because it handles vibration fatigue a bit better and, surprisingly, deals with deck crown variations. Many customers say they see steadier flow and less “plastering” when switching to a quality Shale Shaker Screen in the soft-hook format.

Where it fits

- Oil & gas drilling: top shaker positions, especially API 60–140 ranges.

- HDD and trenchless jobs: clay-heavy returns where flexibility helps.

- Geothermal and CBM: mixed solids, variable flow days.

Key specifications (typical)

| Product | Hook Strip Soft Screen (soft surface, no rigid plate) |

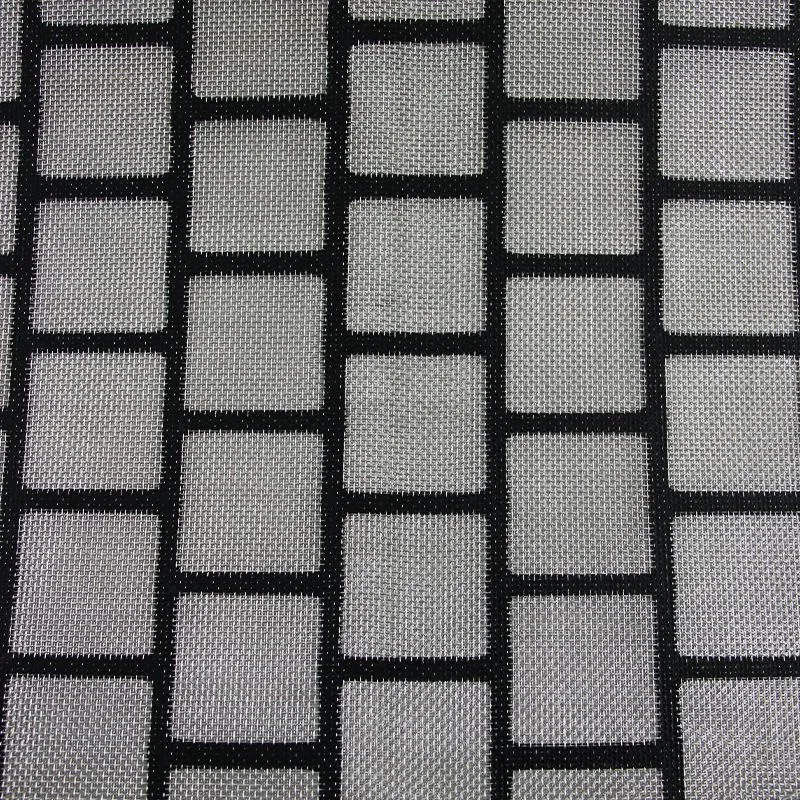

| Mesh/Layer | 2–3 layers SS304/SS316; backing mesh optional |

| API designation | API 40–200 (per API RP 13C) |

| D100 cut point | ≈ 390 μm (API 40) to ≈ 73 μm (API 200), real-world use may vary |

| Conductance | ≈ 1.2–6.5 kd/mm (lab), mud dependent |

| Hook type | Steel hook strip; epoxy-bonded edges |

| Dimensions | Common OEM fits (e.g., 585×1165 mm; 635×1250 mm), custom available |

How it’s made (short version)

Materials: SS304/SS316 wire cloth, mild-steel hook strips, solvent-resistant epoxy. Methods: mesh layering, tensioning, adhesive lamination, edge sealing. QA: API RP 13C labeling (D100, conductance), mesh count check per ASTM E11, and, I guess when needed, salt-spray on coated parts per ASTM B117. Typical service life runs 120–300 hours; I’ve seen more on water-based mud with good solids loading control.

Why choose a soft-style Shale Shaker Screen?

- Higher processing efficiency on variable flowrates.

- Better vibration compliance; reduces corner-blowouts.

- Faster field installs with hook strips—less fight, more uptime.

Vendor comparison (snapshot)

| Criteria | HF Petro (Anping) | Vendor A | Vendor B |

|---|---|---|---|

| API RP 13C labeling | Yes (batch tested) | Claims yes | Partial |

| Customization | Sizes, layers, logos | Limited | MOQ required |

| Lead time | 7–15 days typical | 15–30 days | Around 20 days |

| Warranty/Support | Batch traceability | Standard | Standard |

Customization, quick hits

- API range, mesh layering, and wire grade (SS304/316).

- OEM fit: Derrick, Swaco, NOV, FSI, or custom frame sizes.

- Private label printing and color-coded side strips.

Field notes (real rigs)

Middle East land rig, OBM: replacing older panels with soft-hook API 120 cut NPT by ≈18% while keeping PV stable—mud man was happy. Permian HDD spread: sticky clays; operators reported 25–30% longer runtime before washout on the lead shaker. That’s anecdotal, sure, but we heard it more than once.

Compliance and documentation

Factory maintains ISO 9001 quality procedures, API RP 13C labeling for D100 and conductance, mesh checks per ASTM E11. Certificates and batch test reports are available on request—useful when the auditor comes calling.

Citations

- API RP 13C: Drilling Fluids Processing Measurement [American Petroleum Institute]. https://www.api.org

- ASTM E11: Standard Specification for Woven Wire Test Sieve Cloth. https://www.astm.org/e0011

- ISO 9001:2015 Quality Management Systems. https://www.iso.org/iso-9001-quality-management.html

- IADC/SPE resources on shaker screen performance and solids control. https://www.iadc.org | https://www.spe.org

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025