- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen - Anping County Hangshun|Drilling Fluid Separation&Precision Engineering

Introduction to Shale Shaker Screens

The shale shaker screen is a critical component in modern drilling systems, specifically engineered to separate solid cuttings from drilling mud. This fine mesh, typically composed of dual or triple layers of stainless steel wire cloth, plays a pivotal role in maintaining the efficiency and sustainability of drilling operations. By capturing solid particles and allowing excess mud to drain back into the tank, these screens ensure optimal fluid management, reducing waste and enhancing operational safety.

Key Features and Advantages

Shale shaker screens are designed with advanced engineering to meet the demanding requirements of the drilling industry. Their standout features include:

- High Strength and Load Capacity: Constructed from durable stainless steel or carbon steel, these screens can withstand heavy drilling fluid loads, ensuring long-term reliability.

- Exceptional Filtering Accuracy: Multi-layered mesh configurations allow precise separation of solid particles, enhancing the quality of the recycled drilling fluid.

- Wear and Corrosion Resistance: Surface treatments like coating protect the screens from abrasive materials and harsh environments, extending their service life.

- Adaptability: Available in various types—such as wave, steel frame, and composite frame—these screens can be tailored to specific drilling conditions and equipment.

- Easy Maintenance: Designed for straightforward installation and upkeep, minimizing downtime and operational costs.

As noted by the National Institute of Standards and Technology (NIST), "Precision engineering in industrial components is essential for ensuring operational efficiency and safety in critical applications" (NIST). This principle underpins the design of shale shaker screens, which are engineered to meet rigorous performance standards.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue; customizable) |

| Production Process | Weaving and perforating |

| Type | Steel frame, composite frame, hook strip, wave |

| Standards Compliance | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

The versatility of these screens is further highlighted by their ability to conform to international standards, ensuring compatibility with a wide range of drilling equipment and regulatory requirements.

Applications in the Drilling Industry

Shale shaker screens are indispensable in various drilling scenarios, including:

- Oil and Gas Drilling: Essential for separating cuttings from drilling mud in conventional and unconventional reservoirs.

- Horizontal Directional Drilling: Ensures efficient fluid management in non-excavation projects.

- Coal Bed Methane and Shale Gas Extraction: Critical for maintaining fluid purity in environmentally sensitive areas.

- Environmental Protection: Used in sludge treatment to purify water and reduce contamination risks.

These applications underscore the screens' role in promoting sustainable drilling practices and compliance with environmental regulations.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd

As a leading manufacturer in the industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd specializes in producing high-quality shale shaker screens tailored to diverse drilling needs. With a commitment to innovation and precision, the company adheres to international standards such as ISO and API, ensuring that its products meet the highest quality benchmarks. Their expertise in crafting durable, efficient screens has made them a trusted partner for drilling operations worldwide.

-

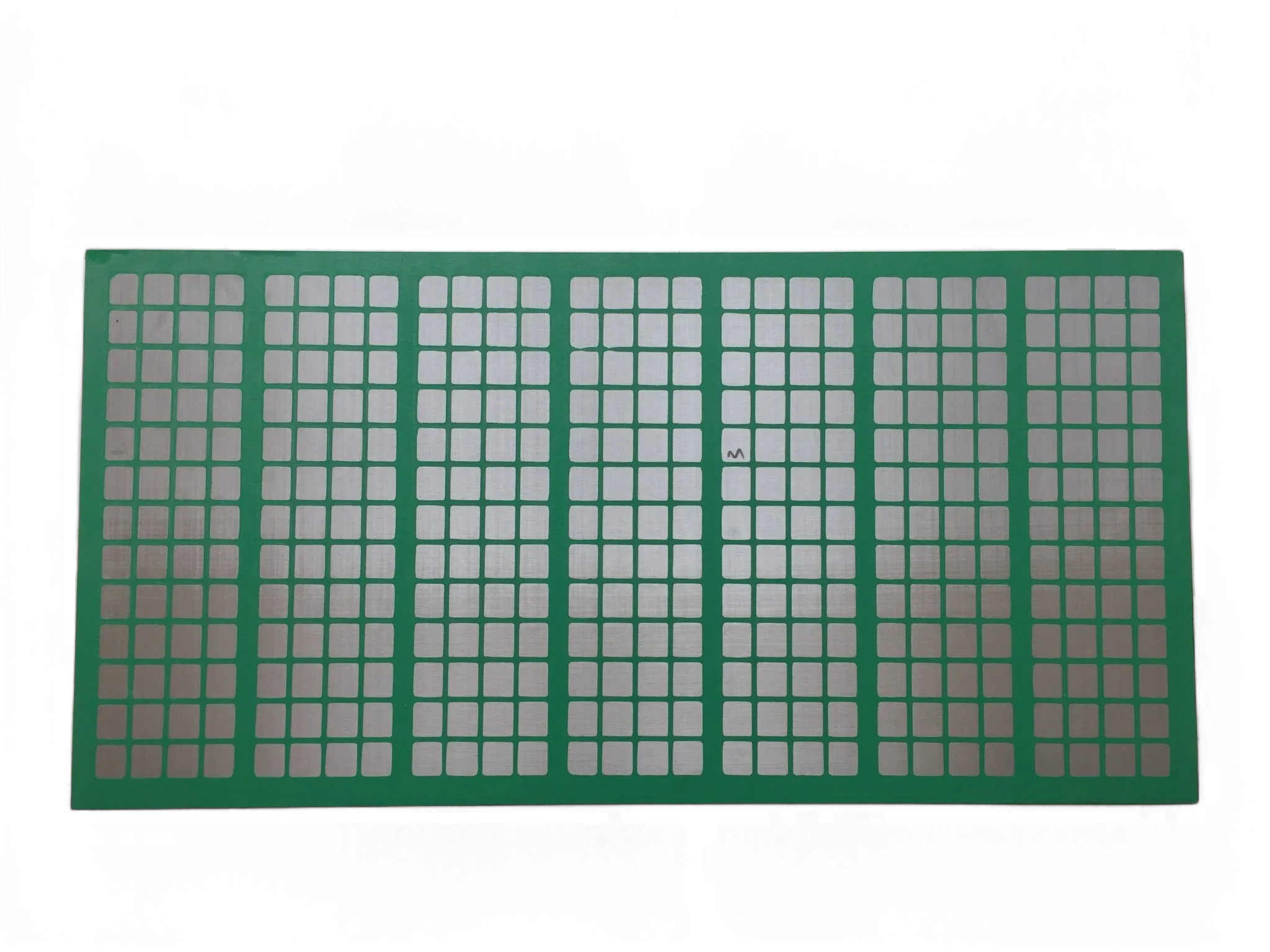

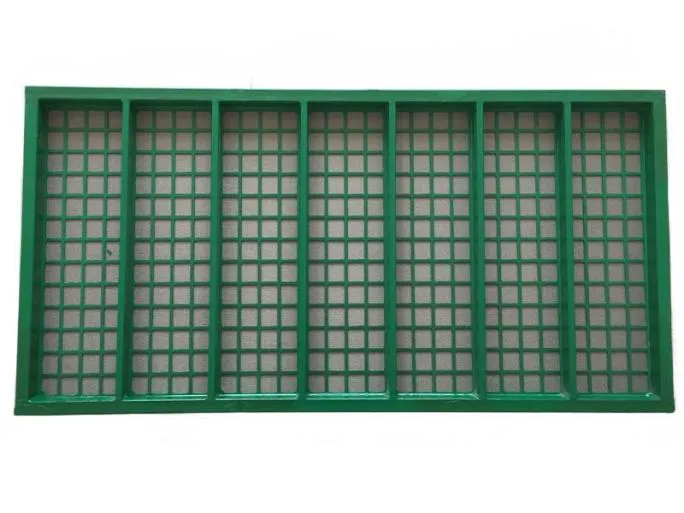

Hook Strip Flat Shale Shaker Screen

Hook Strip Flat Shale Shaker Screen -

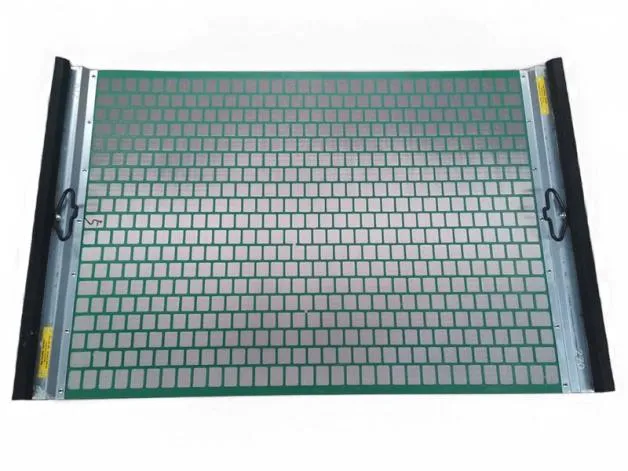

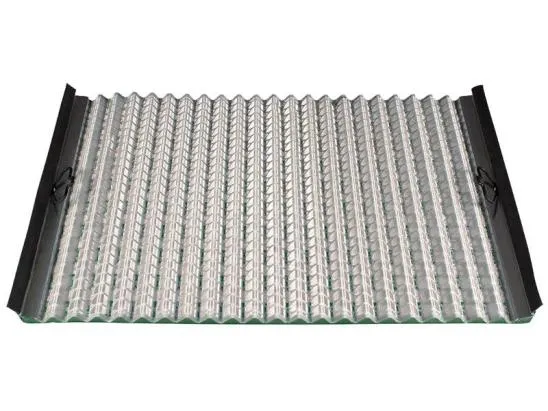

Wave Shale Shaker Screen

Wave Shale Shaker Screen

Choosing the Right Shale Shaker Screen

With multiple types available, selecting the optimal screen depends on specific drilling conditions:

- Wave Screens: Offer the highest processing efficiency, ideal for high-volume operations.

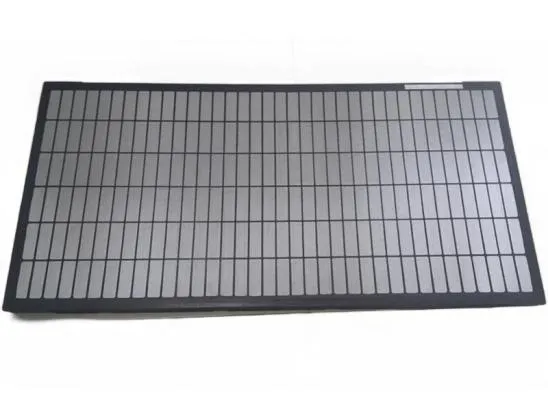

- Steel Frame Screens: Provide superior load-bearing capacity, suitable for heavy-duty applications.

- Composite Frame Screens: Balance durability and flexibility, adapting to varied equipment setups.

By evaluating factors such as drilling fluid weight, cuttings size, and operational environment, users can choose the most effective solution for their needs.

Conclusion

Shale shaker screens represent a vital advancement in drilling technology, combining durability, precision, and adaptability to meet the challenges of modern oil and gas operations. As highlighted by NIST, "Accurate measurement and standards are foundational to technological progress" (NIST). The rigorous engineering and compliance of these screens exemplify this principle, ensuring reliable performance in critical applications. For businesses seeking to enhance efficiency and sustainability, investing in high-quality shale shaker screens is a strategic decision that aligns with industry best practices.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025