- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Durable Steel Walkway Grating | Safe & Strong Industrial Access

Introduction to Industrial Walkway Grating Solutions

In industrial environments, safety, durability, and operational efficiency are paramount. steel walkway grating stands as a foundational component for various access systems, platforms, and trench covers. Engineered for high-load bearing capacity and excellent slip resistance, these robust structures are critical in ensuring safe passage and optimal functionality across diverse sectors. This comprehensive guide delves into the specifics of modern grating technology, offering insights for B2B decision-makers and engineering professionals seeking reliable and high-performance solutions for their infrastructure needs.

Our discussion will cover the intricate manufacturing processes, technical advantages, diverse application scenarios, and key considerations for vendor selection and customization. We aim to provide a data-driven perspective to enhance understanding and confidence in selecting optimal walkway solutions.

Current Industry Trends in Metal Walkways Gratings

The industrial grating sector is continually evolving, driven by stringent safety regulations, demands for enhanced material performance, and a push towards sustainable practices. Key trends include:

- Advanced Material Science: Increased adoption of higher-grade steels (e.g., SS316 for extreme corrosion resistance) and specialized coatings to extend service life in harsh environments.

- Modular and Pre-engineered Systems: A growing preference for modular steel walkway grating systems that offer faster installation, reduced on-site labor, and greater design flexibility.

- Emphasis on Anti-Slip Technologies: Beyond standard serrated surfaces, innovations in anti-slip coatings and patterns are being integrated to meet increasingly strict occupational safety standards, particularly for `[walkway grates]` in wet or oily conditions.

- Digital Design and Fabrication: CAD/CAM and CNC machining are streamlining the design and manufacturing process, allowing for greater precision and the creation of highly customized solutions with shorter lead times.

- Sustainability Focus: Manufacturers are exploring more energy-efficient production methods and sourcing recycled materials where feasible, aligning with global environmental objectives.

- Global Infrastructure Development: Significant investment in energy, petrochemical, and municipal infrastructure projects worldwide continues to fuel demand for reliable `[metal walkways gratings]`.

These trends underscore a commitment to delivering superior performance, longevity, and safety in industrial applications.

Manufacturing Process of Steel Walkway Grating

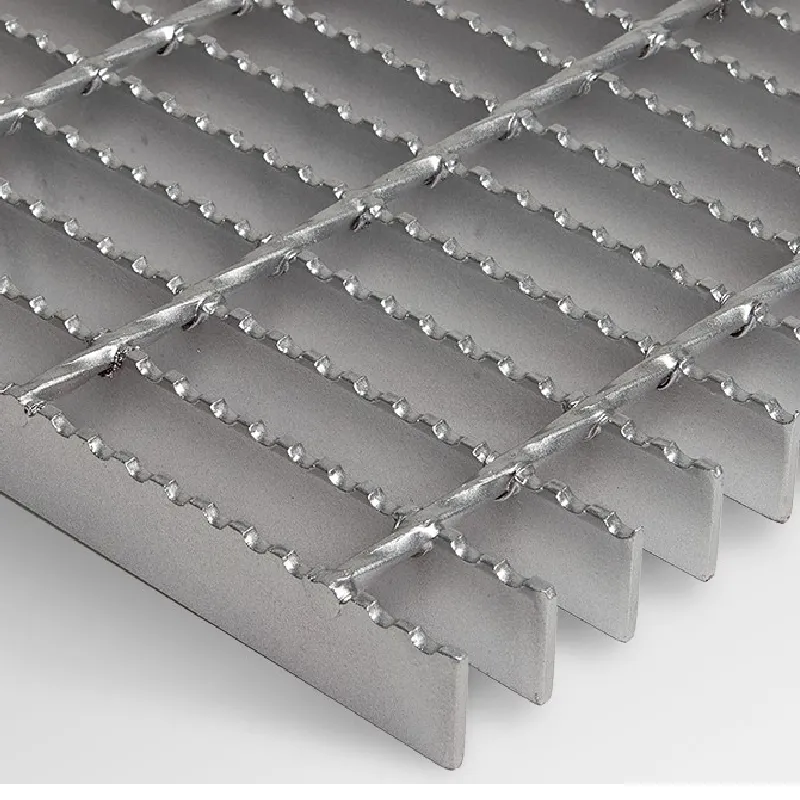

The production of high-quality steel walkway grating involves a series of precision-engineered steps, ensuring structural integrity and adherence to international standards like ISO 9001 and ANSI/NAAMM MBG 531-09. The typical process flow includes:

1. Material Selection & Preparation

High-grade carbon steel (e.g., Q235, Q345) or stainless steel (e.g., SS304, SS316) is selected based on application requirements for strength and corrosion resistance. Materials are precisely cut to size, often using advanced CNC plasma or laser cutting for accuracy.

2. Bearing Bar Slotting

Bearing bars are notched or slotted to precise depths and intervals. This step is crucial for the subsequent insertion of cross bars, ensuring a tight, interlocking fit, particularly for forge-welded or pressure-locked gratings.

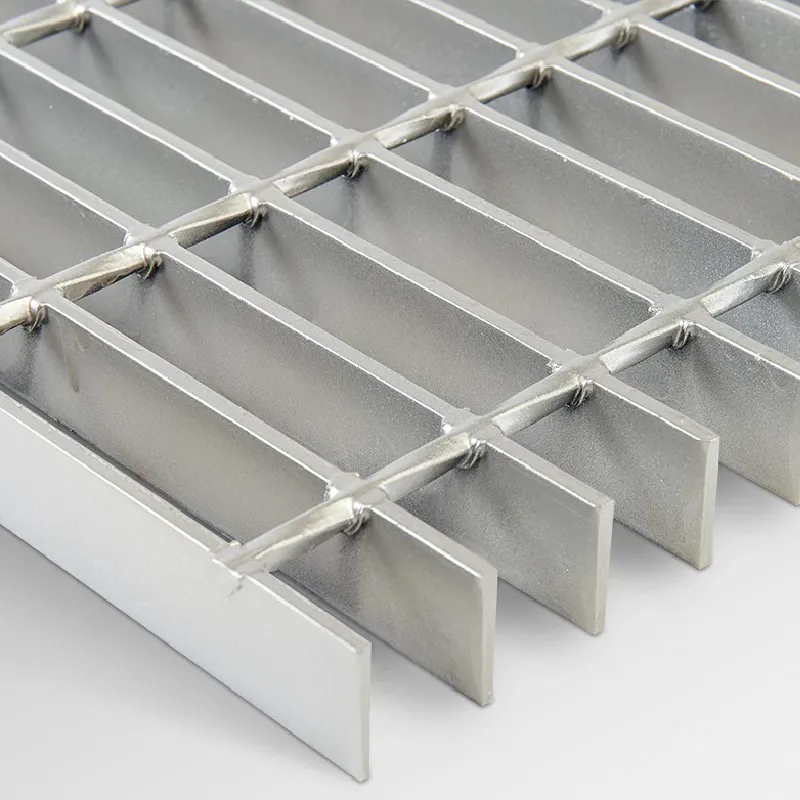

3. Welding/Press-Locking

Cross bars are then integrated into the slotted bearing bars. This is typically achieved via high-pressure resistance welding (forge welding), which fuses the two components into a monolithic panel, or by press-locking, where cross bars are hydraulically pressed into pre-punched holes in the bearing bars.

4. Edge Banding & Trimming

After welding, the grating panels are accurately trimmed to final dimensions. Edge bars are often welded around the perimeter to provide additional strength, improve aesthetics, and protect the panel edges, especially for `[steel walkway mesh]` intended for heavy-duty use.

5. Surface Treatment

For carbon steel gratings, hot-dip galvanization is the most common surface treatment, offering superior corrosion resistance (per ASTM A123 standards). Other options include painting, powder coating, or electropolishing for stainless steel for specific aesthetic or hygiene requirements.

6. Quality Control & Testing

Each batch undergoes rigorous inspection, including visual checks for defects, dimensional verification, load-bearing tests, and coating thickness measurements. This ensures the finished product meets all specified performance criteria and safety standards, guaranteeing a long service life even in demanding applications like petrochemical or power generation facilities.

Technical Specifications and Performance Parameters

Understanding the technical specifications of steel walkway grating is essential for selecting the appropriate product for specific load requirements and environmental conditions. Key parameters include:

- Bearing Bar Dimensions: Refers to the height (depth) and thickness of the main load-carrying bars. Common depths range from 20mm to 100mm, and thicknesses from 3mm to 10mm.

- Bearing Bar Pitch: The center-to-center distance between bearing bars. Standard pitches include 30mm, 40mm, and 60mm, influencing open area and load distribution.

- Cross Bar Pitch: The center-to-center distance between cross bars. Typical pitches are 50mm or 100mm.

- Material Grade: Specifies the steel alloy (e.g., Q235, Q345, SS304, SS316), dictating strength, weldability, and corrosion resistance.

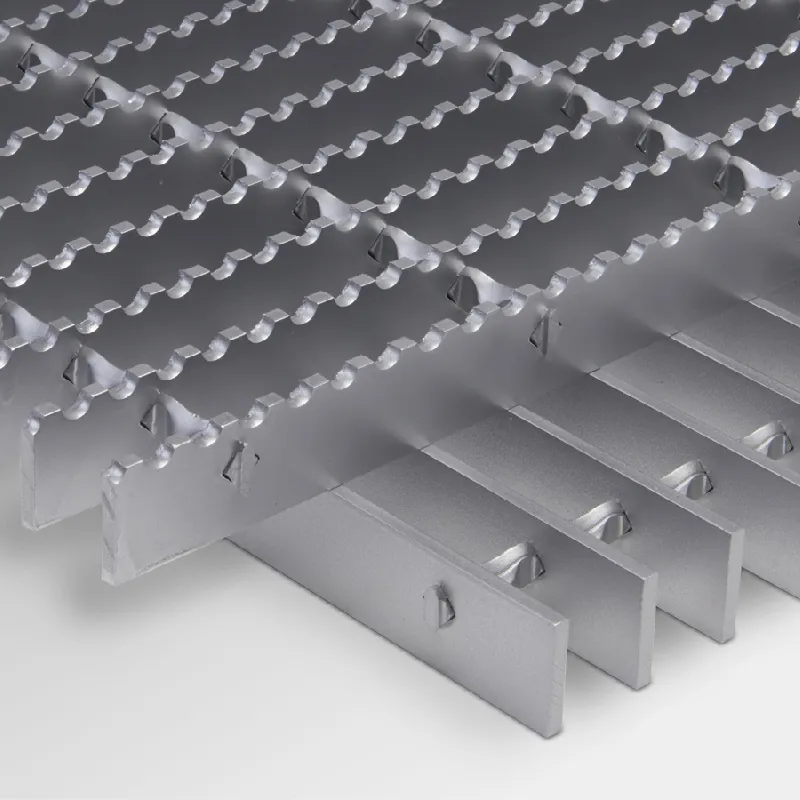

- Surface Finish: Plain or serrated (anti-slip). Serrated surfaces provide enhanced traction, crucial for `[walkway grates]` in hazardous areas.

- Surface Treatment: Hot-dip galvanized, painted, self-color, or electropolished. Galvanization typically provides a minimum zinc coating thickness of 65 µm for enhanced longevity.

Typical Steel Grating Specification Table (Forge-Welded)

| Parameter | Description | Common Values / Range |

|---|---|---|

| Bearing Bar Depth | Height of the load-carrying bar. | 25mm, 30mm, 32mm, 40mm, 50mm, 60mm (up to 100mm) |

| Bearing Bar Thickness | Thickness of the load-carrying bar. | 3mm, 4mm, 5mm (up to 10mm) |

| Bearing Bar Pitch | Center-to-center spacing of bearing bars. | 30mm, 40mm, 60mm |

| Cross Bar Pitch | Center-to-center spacing of cross bars. | 50mm, 100mm |

| Material Grades | Standard for carbon and stainless steel. | Q235, Q345, SS304, SS316 |

| Load Capacity | Distributed load rating per square meter (varies by span and bar size). | Up to 100 KN/m² (specific to configuration) |

| Deflection Limit | Maximum allowable deflection under load (e.g., L/200 for pedestrian traffic). | Span/200 (Pedestrian), Span/300 (Vehicular) |

| Surface Options | Plain or serrated (anti-slip). | Plain, Serrated |

Technical Advantages of Steel Walkway Grating

The widespread adoption of steel walkway grating across demanding industrial environments is attributed to its inherent technical advantages:

- High Strength-to-Weight Ratio: Steel gratings provide exceptional load-bearing capacity with a relatively low self-weight, minimizing structural support requirements and overall material costs. This is particularly beneficial for elevated platforms and mezzanines.

- Superior Durability & Service Life: Manufactured from robust steel alloys and often protected by hot-dip galvanization, these gratings offer outstanding resistance to impact, abrasion, and fatigue. This translates to a service life often exceeding 20 years, even in harsh conditions.

- Excellent Corrosion Resistance: Hot-dip galvanization provides a metallurgical bond between zinc and steel, offering sacrificial and barrier protection against rust and corrosive agents. Stainless steel options further enhance this for chemical processing plants or marine environments.

- Enhanced Safety Features: Serrated surfaces significantly increase coefficient of friction, providing superior slip resistance in oily, wet, or icy conditions, thereby reducing workplace accidents. The open mesh design prevents the accumulation of water, debris, and snow.

- Optimal Ventilation and Light Penetration: The open grid structure allows for unrestricted airflow and light transmission, contributing to better ventilation in enclosed spaces and reducing the need for artificial lighting below, potentially leading to energy savings.

- Ease of Installation and Maintenance: Grating panels are typically supplied in standard sizes, making installation straightforward with simple clamping systems. Their self-cleaning properties and durable finishes require minimal maintenance, reducing operational expenditures.

- Versatility in Design: Available in various bar sizes, spacing, and materials, allowing for precise customization to meet specific load, span, and aesthetic requirements.

Application Scenarios and Target Industries

The robust and versatile nature of `[metal walkways gratings]` makes them indispensable across a multitude of industrial and commercial applications. Their ability to withstand heavy loads, corrosive elements, and provide safe passage is critical in diverse sectors:

- Petrochemical and Oil & Gas: Widely used for offshore platforms, refineries, chemical plants, and processing facilities. Applications include elevated walkways, maintenance platforms, trench covers for pipelines, and stair treads, where corrosion resistance and load capacity are vital.

- Power Generation: Essential for power plants (coal, gas, nuclear, renewable energy) as access platforms around boilers, turbines, and generators, as well as for catwalks, cable trench covers, and substations.

- Metallurgy and Mining: Provides durable flooring for smelters, steel mills, and mining operations, enduring extreme temperatures, heavy machinery traffic, and abrasive conditions. Used for mill floors, conveyor walkways, and crushing plant access.

- Water Treatment & Municipal Services: Utilized in water treatment plants, sewage facilities, and pumping stations for walkways, screen covers, and grating over open sumps, leveraging its corrosion resistance and open design for drainage.

- Manufacturing & Warehousing: Employed for mezzanine flooring, machine platforms, crossovers, and dock areas where heavy foot traffic and material handling equipment require robust and safe surfaces.

- Architectural and Commercial: Increasingly adopted for building facades, sun screens, ventilation grilles, and contemporary public walkways due to its modern aesthetic and functional benefits.

- Marine and Shipbuilding: `[Steel walkway mesh]` is critical for ship decks, engine rooms, gangways, and dock access, benefiting from its corrosion resistance in saltwater environments.

These applications demonstrate the integral role `[walkway grates]` play in ensuring operational safety and structural integrity across heavy industry.

Customized Steel Walkway Grating Solutions

Recognizing that no two industrial projects are identical, reputable manufacturers offer comprehensive customization options for steel walkway grating to meet precise project specifications and challenging site conditions. These tailored solutions ensure optimal fit, function, and performance:

- Tailored Dimensions: Grating panels can be fabricated to exact lengths and widths, including intricate cuts for pipe penetrations, column outlines, or curved structures, minimizing on-site modifications.

- Specific Material Grades: Selection of carbon steel (e.g., Q235, Q345) for general industrial use or various grades of stainless steel (e.g., SS304, SS316, 316L) for highly corrosive environments, food processing, or architectural applications.

- Load-Bearing and Deflection Requirements: Engineers can specify bearing bar depth and thickness, as well as pitch, to achieve precise load ratings and deflection limits necessary for heavy machinery, vehicular traffic, or specific pedestrian loads.

- Specialized Surface Treatments: Beyond standard hot-dip galvanization, options include specific paint systems (epoxy, polyurethane) for color matching or added chemical resistance, or electropolishing for a smoother, highly sanitary finish on stainless steel.

- Integrated Accessories: Custom solutions can include integrated toe plates, stair nosings, specialized attachment clips, or cut-outs for equipment access, fabricated and pre-assembled to streamline installation.

- Engineering and Design Support: Reputable vendors provide extensive engineering support, including CAD drawings, load tables, and detailed layout plans to ensure the customized `[steel walkway mesh]` perfectly integrates with the overall project design.

This ability to provide bespoke solutions, backed by technical expertise, is a significant advantage for complex industrial projects.

Vendor Comparison and Selection Criteria

Choosing the right supplier for steel walkway grating is crucial for project success. A robust vendor comparison considers more than just price; it encompasses quality, reliability, and support. Key criteria include:

- Certifications and Compliance: Verify adherence to international standards (e.g., ISO 9001 for quality management, specific material standards like ASTM, EN).

- Manufacturing Capabilities: Assess the manufacturer's capacity, technology (e.g., automated forge welding), and ability to handle large-scale or complex custom orders.

- Experience and Reputation: Look for a proven track record, years of service in relevant industries, and positive client testimonials or references.

- Product Range and Customization: A broad product portfolio and strong customization capabilities indicate versatility and problem-solving expertise.

- Technical Support and Engineering Expertise: Availability of pre-sales consultation, engineering design assistance, and post-sales technical support.

- Lead Times and Logistics: Evaluate consistency in meeting deadlines and efficient global or regional logistics for timely delivery.

- Warranty and After-Sales Service: Understand the warranty terms and the level of commitment to long-term customer satisfaction and support.

Grating Product Features Comparison

| Feature | Forge Welded Grating | Press-Locked Grating | Swage-Locked Grating (e.g. for `[steel walkway mesh]`) |

|---|---|---|---|

| Joint Strength | Excellent (fused metal joint), high rigidity. | Very Good (mechanical interlock), moderate rigidity. | Good (swaged and twisted), good rigidity. |

| Load Capacity | Highest load-bearing capacity for equivalent dimensions. | High, slightly lower than forge-welded. | Moderate to high, dependent on bar size. |

| Aesthetics | Clean, uniform appearance. | Very clean, architectural appeal. | Distinct visual pattern. |

| Applications | Heavy-duty industrial, power plants, offshore. | Architectural, light industrial, municipal. | General industrial, security fencing, light traffic. |

| Corrosion Resistance (Galvanized) | Excellent, robust coating. | Excellent, uniform coating on all surfaces. | Excellent, uniform coating. |

Real-World Application Case Studies

Case Study 1: Petrochemical Refinery Expansion

Client: Major International Energy Company

Challenge: Design and install extensive elevated walkways and platforms across a new refinery unit, requiring exceptional corrosion resistance, high load capacity for personnel and light equipment, and compliance with stringent safety standards for `[metal walkways gratings]` in potentially explosive atmospheres.

Solution: We supplied over 15,000 square meters of hot-dip galvanized steel walkway grating with 32x5mm bearing bars at 30mm pitch, featuring a serrated surface for enhanced slip resistance. Custom cuts and banding for pipe penetrations and structural elements were pre-fabricated to minimize on-site welding and hot work permits. The material selected was Q345 steel for its superior strength.

Outcome: The project was completed on schedule, with the pre-fabricated grating reducing installation time by an estimated 20%. The robust galvanization ensured long-term protection against the highly corrosive petrochemical environment, contributing to the facility's projected 30-year operational life without significant grating maintenance.

Case Study 2: Municipal Water Treatment Plant Upgrade

Client: City Water Authority

Challenge: Replace deteriorating concrete and fiberglass grating in a wastewater treatment facility, requiring materials resistant to chemical exposure, easy to clean, and capable of handling continuous foot traffic and periodic heavy maintenance loads. Adequate light penetration and ventilation were also critical.

Solution: We provided custom-fabricated steel walkway grating made from SS316 stainless steel, with 25x3mm bearing bars at a 40mm pitch. The grating was electropolished to ensure maximum corrosion resistance and a smooth, hygienic surface that resists biological growth and is easy to jet-wash. Integrated kick plates and custom access hatches were included.

Outcome: The new `[walkway grates]` significantly improved safety and operational hygiene. The stainless steel solution demonstrated superior longevity in the chemically aggressive environment compared to previous materials, drastically reducing maintenance cycles and costs over the first five years of operation. The open area also enhanced lighting in sub-surface areas, leading to improved worker visibility.

Frequently Asked Questions (FAQ) about Steel Walkway Grating

Q1: What is the typical lifespan of hot-dip galvanized steel walkway grating?

A1: In most industrial environments, hot-dip galvanized steel walkway grating can last 20 to 50 years, depending on the corrosivity of the specific atmosphere and the thickness of the zinc coating. Regular inspections and proper installation can extend this lifespan.

Q2: Can steel walkway grating be used outdoors in all weather conditions?

A2: Yes, absolutely. Hot-dip galvanized and stainless steel gratings are specifically designed for outdoor use. Their open mesh design prevents water, snow, and ice accumulation, while serrated surfaces provide excellent anti-slip properties in adverse weather. The coatings ensure protection against elements.

Q3: How do I determine the correct load capacity for my application?

A3: Load capacity depends on the bearing bar depth, thickness, pitch, and the span length of the grating. It's crucial to consult load tables provided by the manufacturer or engage an engineer to calculate the precise requirements based on anticipated static and dynamic loads, deflection limits, and safety factors. Our technical team can assist with these calculations.

Q4: What are the primary differences between forge-welded and press-locked grating?

A4: Forge-welded grating uses high heat and pressure to fuse bearing bars and cross bars, creating a very strong, rigid, monolithic panel, ideal for heavy-duty applications. Press-locked grating involves hydraulically pressing cross bars into pre-punched bearing bars, offering a clean aesthetic and good strength for lighter industrial or architectural use, often seen in `[steel walkway mesh]` designs.

Q5: Is customization available for specific project needs?

A5: Yes, extensive customization options are available, including specific panel dimensions, cut-outs for pipes or columns, various material grades (carbon steel, stainless steel), serrated or plain surfaces, and different finishes (galvanized, painted, electropolished). We work closely with clients to engineer solutions that perfectly fit their unique project requirements.

Lead Time, Warranty, and Customer Support

Lead Time and Fulfillment

Standard steel walkway grating panels typically have a lead time of 2-4 weeks, depending on order volume and current production schedules. Custom-fabricated orders may require 4-8 weeks, factoring in design, material sourcing, specialized manufacturing, and finishing processes. We prioritize transparent communication regarding lead times and leverage efficient logistics networks to ensure timely delivery to project sites worldwide. Expedited options are available for urgent requirements, subject to project scope and material availability.

Warranty Commitments

All our `[metal walkways gratings]` products are backed by a comprehensive warranty, typically covering manufacturing defects and material integrity for a period of 5-10 years from the date of purchase. This warranty reflects our confidence in the quality and durability of our products, manufactured to stringent international standards. Specific warranty terms may vary based on product type and application, and detailed warranty documentation is provided with every order.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We offer robust customer support to ensure optimal performance and satisfaction throughout the product's lifecycle. Our services include:

- Technical Assistance: A team of experienced engineers is available to provide guidance on installation, maintenance best practices, and troubleshooting.

- Replacement Parts & Modifications: We facilitate the provision of replacement panels, clips, or specific components as needed, and can advise on potential modifications or extensions to existing installations.

- Dedicated Account Management: Each client is assigned a dedicated account manager for streamlined communication and personalized service.

- Feedback Mechanism: We actively solicit customer feedback to continuously improve our products and services.

For any inquiries or support, please contact our team via the details provided on our website. We are committed to fostering long-term partnerships built on trust and reliable performance.

Conclusion

The role of steel walkway grating in modern industrial infrastructure cannot be overstated. Its combination of strength, durability, safety features, and adaptability makes it an essential component for ensuring operational efficiency and personnel safety across a vast array of sectors. By understanding the intricate manufacturing processes, technical specifications, and advantages, decision-makers can make informed choices that yield long-term benefits in terms of reliability, reduced maintenance, and adherence to stringent safety standards. Partnering with an experienced and quality-focused manufacturer is paramount to realizing the full potential of these robust industrial solutions.

References

- ASTM A123/A123M-17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ANSI/NAAMM MBG 531-09, Metal Bar Grating Manual.

- ISO 9001:2015, Quality management systems – Requirements.

- Galvanizers Association, "Corrosion Protection by Hot Dip Galvanizing."

- The Steel Construction Institute, "Design and Construction of Composite Slabs and Beams with Steel Decking."

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025