- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen-Anping County Hangshun Wire Mesh | Filtration Efficiency&Durability

Shale shaker screens are critical components in the drilling industry, designed to filter and separate solid cuttings from drilling fluids. These screens play a pivotal role in maintaining the efficiency of drilling operations by ensuring the continuous recycling of drilling mud. This article delves into the features, specifications, applications, and technological advancements of shale shaker screens, while also highlighting the expertise of Anping County Hangshun Wire Mesh Manufacture Co., Ltd, a leading manufacturer in this field.

Understanding Shale Shaker Screens

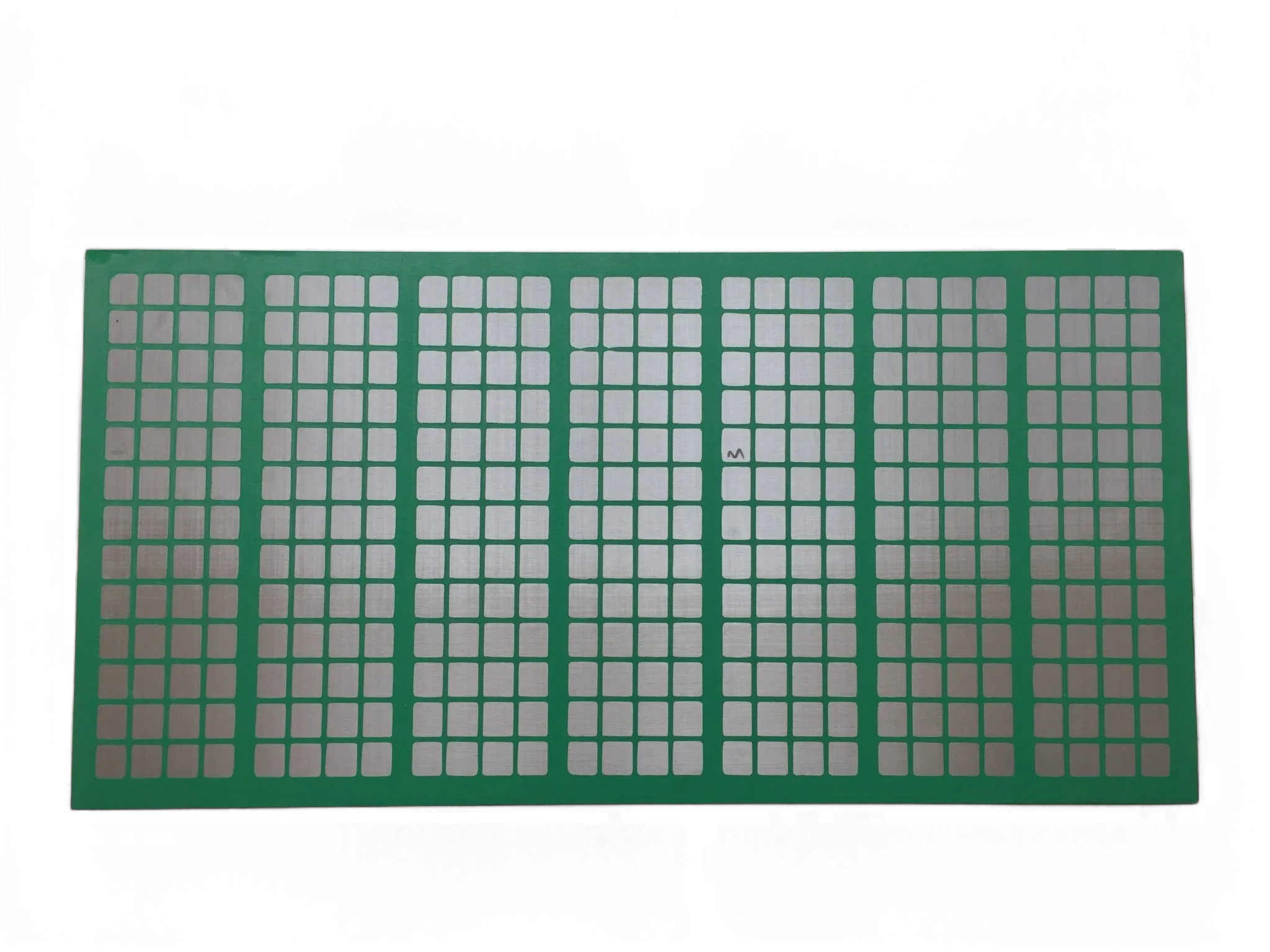

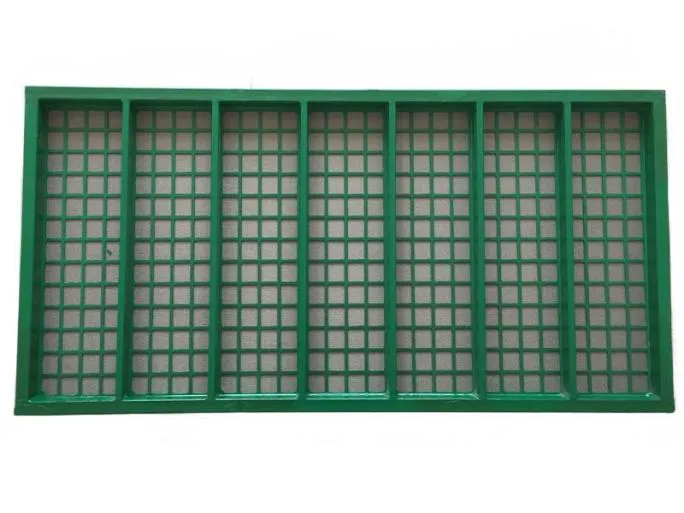

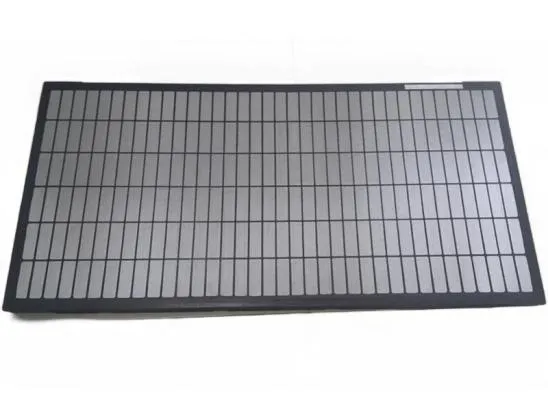

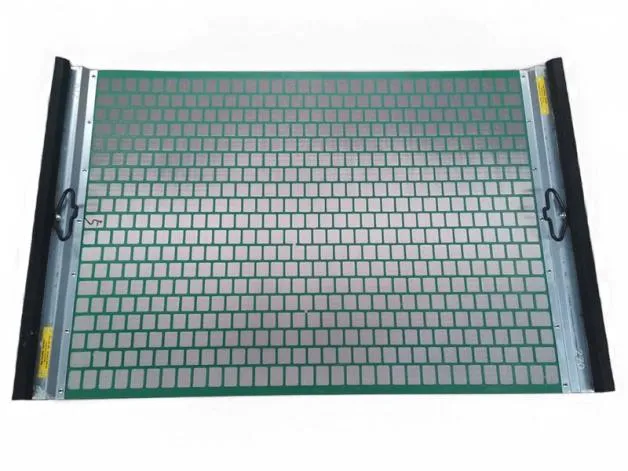

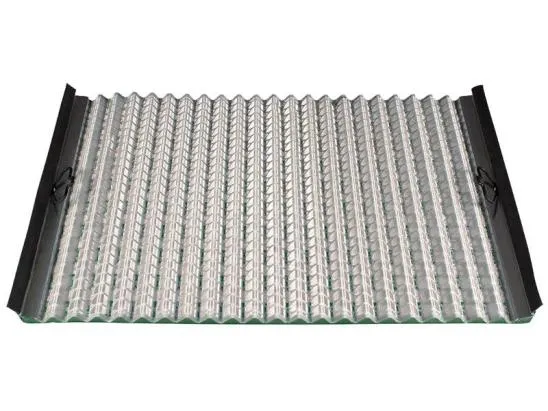

Shale shaker screens are specialized mesh screens used in shale shakers, which are essential equipment in the drilling process. These screens are designed to separate solid particles from drilling mud, a critical step in maintaining the efficiency and sustainability of drilling operations. The mesh structure of these screens—often composed of stainless steel or carbon steel—ensures high filtration accuracy and durability.

According to the National Institute of Standards and Technology (NIST), the precision of filtration systems is vital in industrial applications. Shale shaker screens adhere to standards such as ISO 13501 and API RP 13C, which are referenced in the product specifications. These standards ensure that the screens meet rigorous performance criteria, including high strength, wear resistance, and corrosion resistance (NIST).

Key Features of Shale Shaker Screens

- High Strength and Bearing Capacity: The screens are engineered to withstand the high loads of drilling fluids, ensuring long-term performance.

- Excellent Filtering Accuracy: Multi-layered designs (dual or triple) allow for precise separation of solids, enhancing the efficiency of the drilling process.

- Wear and Corrosion Resistance: The use of stainless steel ensures longevity even in harsh environments.

- Flexibility and Adaptability: Available in various types, such as steel frame, composite frame, and wave screens, these screens can be customized for different drilling conditions.

- Easy Installation and Maintenance: Designed for quick replacement, reducing downtime and operational costs.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in the Drilling Industry

Shale shaker screens are widely used in various drilling operations, including:

- Oil and Gas Drilling: Essential for separating cuttings from drilling mud in both onshore and offshore environments.

- Coal Bed Methane Drilling: Ensures efficient mud recycling in unconventional gas extraction.

- Shale Gas Drilling: Critical for maintaining the purity of drilling fluids in high-pressure, low-permeability formations.

- Environmental Protection: Used in sludge treatment and mud purification for river and soil remediation projects.

These screens are also integral to non-excavation horizontal directional drilling, where minimizing environmental impact is a priority. The NIST emphasizes the importance of such technologies in modern drilling practices, highlighting their role in sustainable resource extraction (NIST).

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Anping County Hangshun Wire Mesh Manufacture Co., Ltd is a leading manufacturer of shale shaker screens, known for its commitment to quality and innovation. Located in Hebei Province, China, the company has established itself as a trusted supplier in the global drilling industry. With a focus on precision engineering and customer-centric solutions, Hangshun Wire Mesh ensures that its products meet the highest standards of performance and reliability.

The company’s product page showcases a wide range of shale shaker screens, including steel frame, composite frame, and wave screens, each tailored to specific drilling requirements. Their website provides detailed information on product specifications, applications, and technical support.

Why Choose Anping County Hangshun Wire Mesh?

Several factors set Anping County Hangshun Wire Mesh Manufacture Co., Ltd apart in the competitive market:

- Comprehensive Product Range: Offers shale shaker screens in multiple configurations to suit diverse drilling conditions.

- Adherence to International Standards: Products comply with ISO 13501 and API RP 13C, ensuring global compatibility and reliability.

- Customization Options: Capable of producing screens in custom colors and sizes to meet specific client needs.

- Expertise in Material Science: Utilizes advanced stainless steel and carbon steel to enhance durability and performance.

Conclusion

Shale shaker screens are indispensable in modern drilling operations, offering a reliable solution for separating solids from drilling fluids. With their high strength, filtration accuracy, and adaptability, these screens are a cornerstone of efficient and sustainable drilling practices. Anping County Hangshun Wire Mesh Manufacture Co., Ltd exemplifies the industry's best practices, delivering high-quality, standardized products that meet the demands of global drilling projects.

For more information on shale shaker screens and their applications, visit the product page or explore the company website.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/.

Standards referenced: ISO 13501, API RP 13C, GBT 11648, and GBT 11650.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025