- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen - Anping County Hangshun Wire Mesh Manufacture Co., Ltd | High Filtration Accuracy & Durable Design

Shale shaker screen is a critical component in modern drilling systems, designed to efficiently separate solid cuttings from drilling fluids. These screens are essential in maintaining the quality and consistency of drilling mud, which is vital for safe and effective drilling operations.

Introduction to Shale Shaker Screens

Shale shaker screens are fine mesh structures, typically composed of stainless steel or carbon steel, used in shale shakers to filter and separate drilling cuttings from mud. These screens are engineered to withstand the harsh conditions of drilling environments while ensuring high filtration accuracy. The multi-layered design—often dual or triple—allows for precise separation of solids, enhancing the overall efficiency of the drilling process.

When drilling operations produce solid cuttings, they are coated in drilling fluid. As these cuttings pass over the shale shaker screens, the screens capture the solid particles while allowing excess mud to drip through. This process not only improves the quality of the drilling fluid but also reduces the risk of equipment damage and environmental contamination.

Key Features of Shale Shaker Screens

- High Strength and Bearing Capacity: Constructed from durable materials, these screens can handle heavy loads of drilling fluid without deforming.

- Excellent Filtering Accuracy: The multi-layered mesh ensures precise separation of solids, even at fine particle sizes.

- High Processing Efficiency: Designs like the wave screen optimize the flow of drilling fluids, enhancing operational efficiency.

- Wear and Corrosion Resistance: Coated surfaces and high-quality materials extend the lifespan of the screens, even in corrosive environments.

- Flexibility and Adaptability: Available in various types (e.g., steel frame, composite, hook strip) to suit different drilling conditions.

- Easy Installation and Maintenance: Designed for quick replacement and minimal downtime, ensuring continuous operation.

Product Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Types of Shale Shaker Screens

There are several types of shale shaker screens, each designed to meet specific operational requirements:

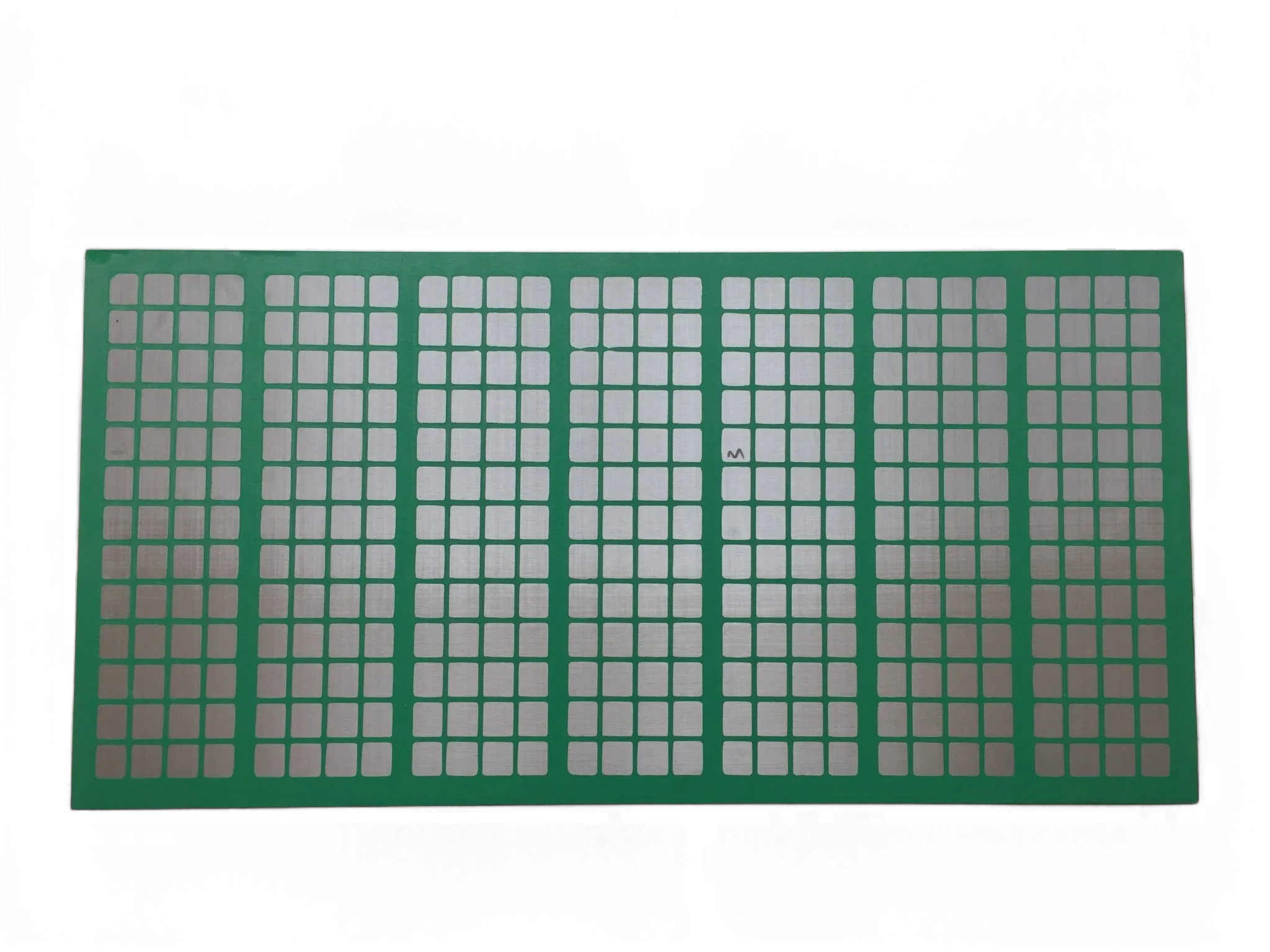

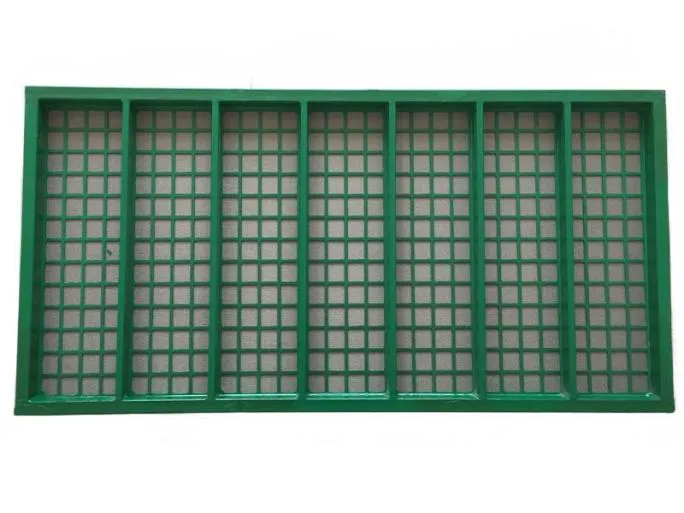

1. Steel Frame Shale Shaker Screen

These screens are ideal for heavy-duty applications due to their robust steel frames. They can bear the highest weight of drilling fluid, making them suitable for large-scale drilling operations. For more details, visit the Steel Frame Shale Shaker Screen page.

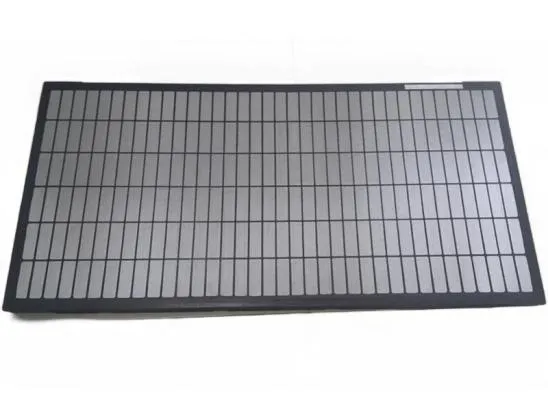

2. Composite Frame Shale Shaker Screen

Combining the benefits of multiple materials, composite frame screens offer a balance of strength and flexibility. They are well-suited for diverse drilling conditions and are known for their durability. Learn more about Composite Frame Shale Shaker Screens.

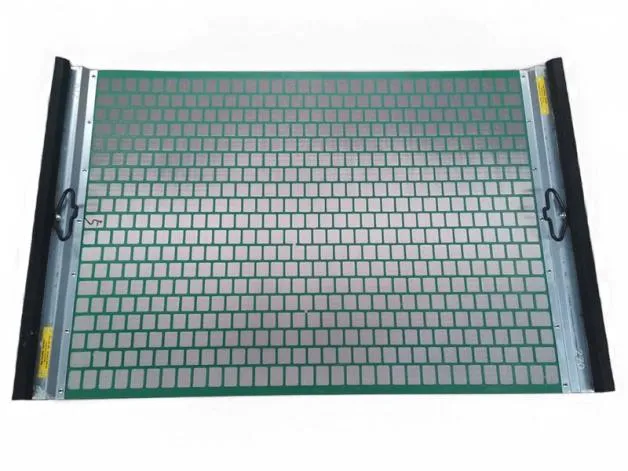

3. Hook Strip Shale Shaker Screen

These screens feature a hook strip design that allows for easy installation and maintenance. They are particularly effective in applications requiring frequent screen changes. Explore the Hook Strip Shale Shaker Screen options.

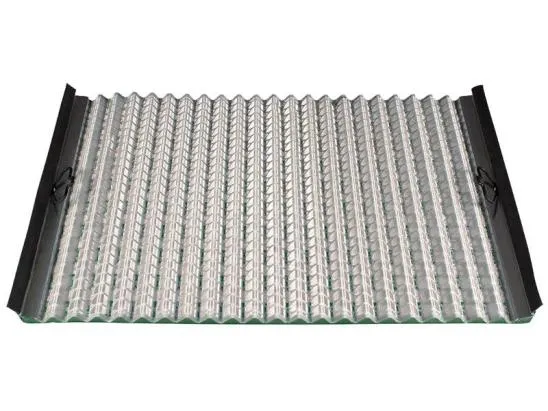

4. Wave Shale Shaker Screen

Wave screens are designed to maximize processing efficiency. Their unique wave pattern ensures even distribution of drilling fluids, reducing the risk of clogging and improving separation accuracy. Discover more about Wave Shale Shaker Screens.

Applications of Shale Shaker Screens

Shale shaker screens are widely used across various industries, including:

- Oil Drilling: Essential for separating cuttings from drilling mud in both onshore and offshore operations.

- Non-Excavation Horizontal Directional Drilling: Ensures efficient mud recycling in trenchless technology.

- Coal Bed Methane Drilling: Maintains the quality of drilling fluids in unconventional gas extraction.

- Shale Gas Drilling: Critical for managing the high volumes of cuttings generated during hydraulic fracturing.

- Environmental Protection: Used in river sludge treatment to purify mud and reduce environmental impact.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Founded in 2005, Anping County Hangshun Wire Mesh Manufacture Co., Ltd is a leading manufacturer of shale shaker screens and other industrial mesh products. The company specializes in producing high-quality, durable screens that meet international standards such as ISO 13501 and API RP 13C. With a focus on innovation and customer satisfaction, Hangshun has established itself as a trusted supplier in the global drilling industry.

For more information about the company and its product range, visit the Anping County Hangshun Wire Mesh Manufacture Co., Ltd website.

Why Choose Our Shale Shaker Screens?

Our shale shaker screens are engineered to deliver superior performance in the most demanding environments. Here are some reasons to choose our products:

- Customization: Available in various mesh sizes, colors, and frame types to suit specific drilling requirements.

- Compliance: Manufactured to meet global standards, ensuring reliability and consistency.

- Expertise: Backed by years of experience and a dedicated R&D team, we provide innovative solutions tailored to the needs of the drilling industry.

- Global Reach: Our products are exported to numerous countries, supported by a network of distributors and technical experts.

Industry Standards and Certifications

Our shale shaker screens comply with the following industry standards:

- ISO 13501: Specifies the requirements for the design and testing of shale shaker screens.

- API RP 13C: A recommended practice for the specification and testing of drilling fluid solids control equipment.

- GBT 11648 and GBT 11650: Chinese national standards for wire mesh and related products.

Environmental and Safety Considerations

Shale shaker screens play a crucial role in reducing the environmental impact of drilling operations. By efficiently separating cuttings from drilling fluids, they help minimize waste and ensure compliance with environmental regulations. Additionally, the wear-resistant and corrosion-resistant properties of our screens enhance safety by reducing the risk of equipment failure and downtime.

Conclusion

Shale shaker screens are indispensable in modern drilling operations, offering a reliable solution for separating solids from drilling fluids. With their high strength, precision, and adaptability, these screens ensure efficient and safe drilling processes. Anping County Hangshun Wire Mesh Manufacture Co., Ltd continues to lead in innovation, providing cutting-edge solutions that meet the evolving needs of the industry.

For more information, visit our Shale Shaker Screen product page.

References

1. National Institute of Standards and Technology (NIST). "Standards and Measurements." Retrieved from https://www.nist.gov.

2. API RP 13C, "Recommended Practice for Specification and Testing of Drilling Fluid Solids Control Equipment."

3. ISO 13501, "Petroleum and natural gas industries — Shale shaker screens — Design and testing."

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025