- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen-Anping County Hangshun Wire Mesh Manufacture Co., Ltd|Solid Control&Drilling Efficiency

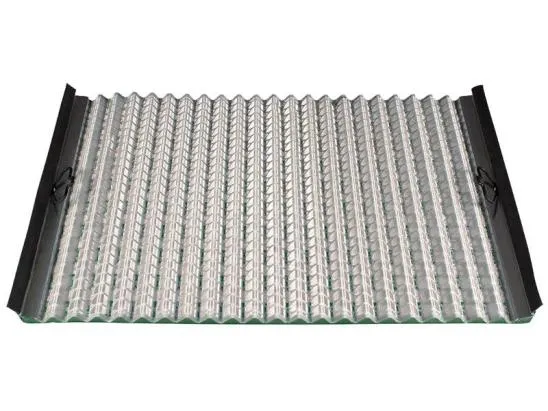

Shale shaker screens are critical components in modern drilling operations, designed to separate solid cuttings from drilling fluids. These fine mesh screens, often composed of stainless steel wire cloths, ensure efficient mud purification and solid control. Explore the full product range to understand how these screens optimize drilling performance.

Understanding Shale Shaker Screens

Shale shaker screens are specialized mesh structures installed within shale shakers, which are essential for processing drilling fluids. As drilling equipment generates cuttings coated in mud, these screens capture solid particles while allowing excess fluid to drain back into the system. This process is vital for maintaining fluid quality and reducing environmental impact.

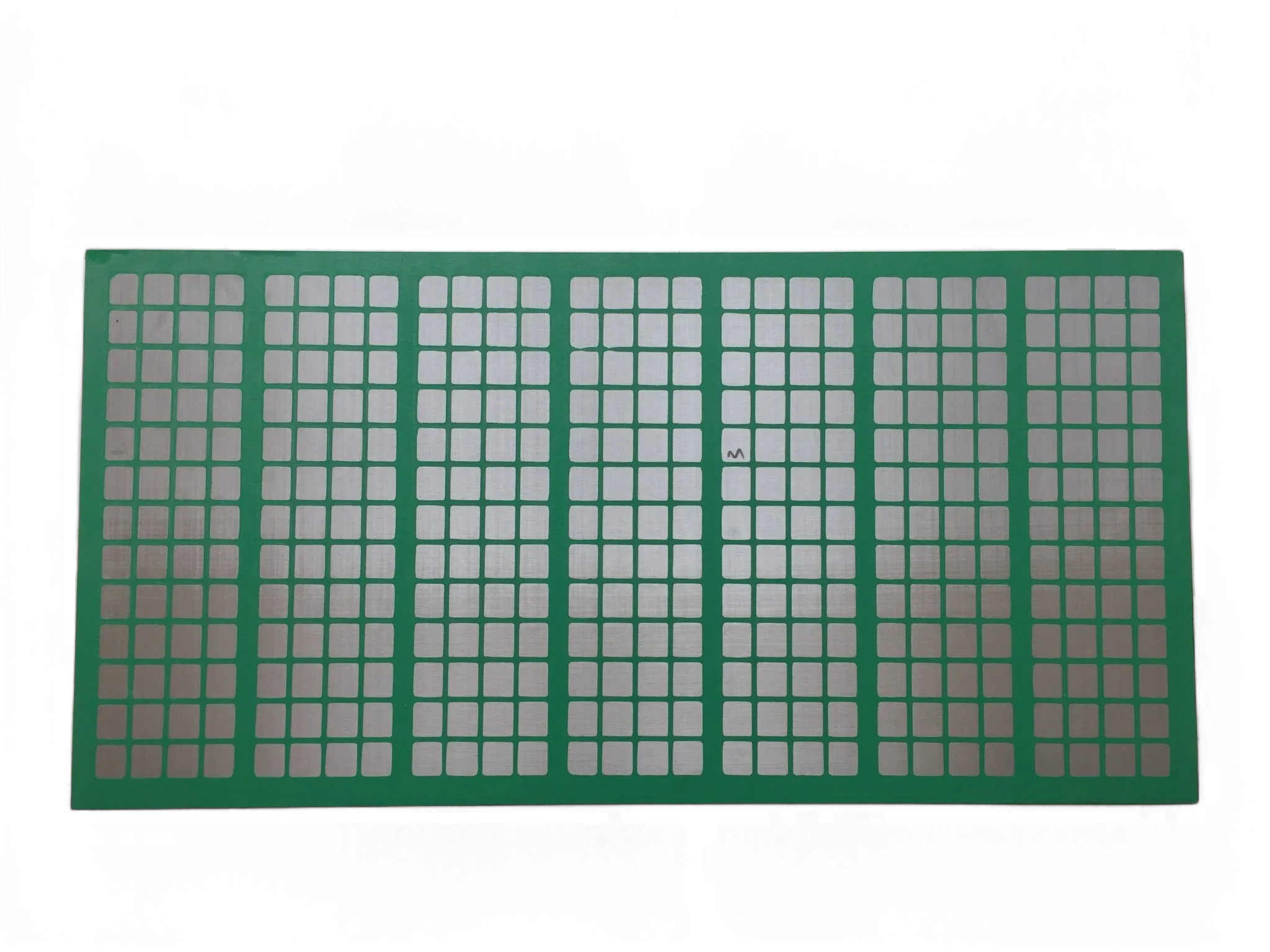

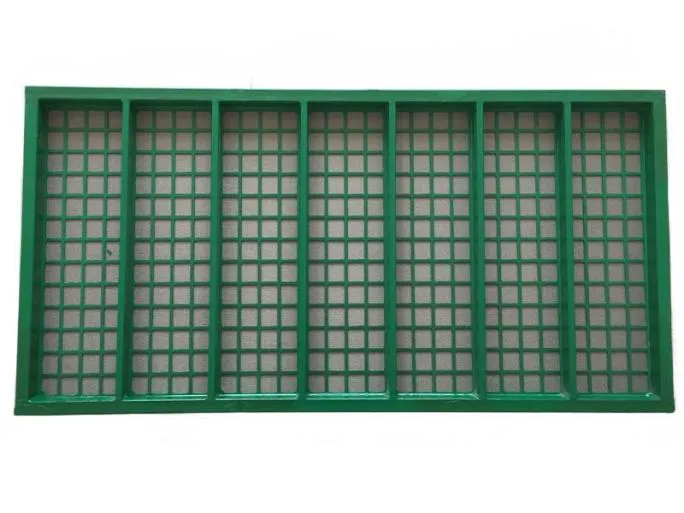

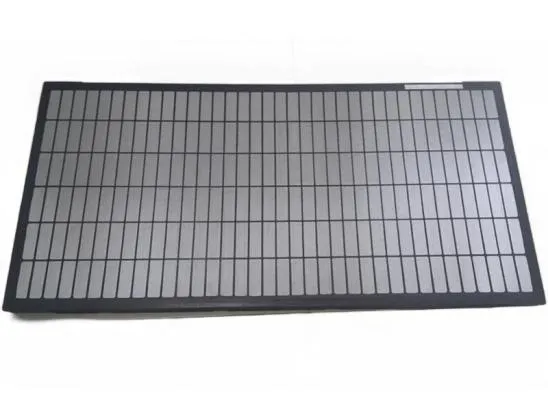

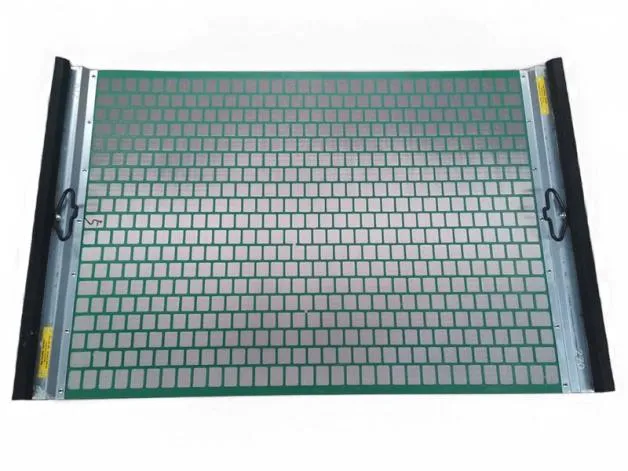

The screens are typically constructed with two or three layers of stainless steel wire cloths, each with varying mesh sizes. This multi-layered design ensures high filtering accuracy, enabling the separation of fine particles. For instance, wave screens are renowned for their processing efficiency, while steel frame screens offer superior load-bearing capacity for heavy drilling fluids. Select the right screen based on your operational requirements.

Key Features of Shale Shaker Screens

- High Strength and Bearing Capacity: Engineered to withstand the rigors of drilling environments, these screens maintain structural integrity under heavy loads.

- Excellent Processing Efficiency: Advanced designs, such as wave screens, maximize throughput while minimizing downtime.

- Wear and Corrosion Resistance: Stainless steel construction ensures longevity, even in harsh conditions.

- Flexibility: Compatible with various shale shaker models, these screens adapt to diverse drilling scenarios.

- Superior Quality Control: Free from defects like bumps, deformation, or solder spatter, ensuring consistent performance.

- Easy Maintenance: User-friendly installation and replacement reduce operational disruptions.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue; custom colors available) |

| Production Process | Weaving and perforating |

| Type | Steel frame, composite frame, hook strip, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in Drilling and Environmental Protection

Shale shaker screens are indispensable in multiple industries, including:

- Oil Drilling: Efficient removal of cuttings from drilling mud, enhancing fluid reusability.

- Coal Bed Methane Drilling: Ensures clean fluid circulation in low-permeability reservoirs.

- Shale Gas Extraction: Critical for managing high-volume cuttings in unconventional plays.

- Environmental Protection: Reduces sludge and contaminant discharge in river and soil remediation projects.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

Founded in Anping County, Hebei Province, Anping County Hangshun Wire Mesh Manufacture Co., Ltd. is a leading manufacturer of high-quality wire mesh products. With over a decade of experience, the company specializes in producing shale shaker screens tailored to global drilling standards. Their commitment to innovation and quality has positioned them as a trusted partner for oil and gas operators worldwide.

As a certified ISO 13501 and API RP 13C compliant manufacturer, Hangshun ensures that every product meets rigorous industry requirements. Their shale shaker screens are designed to withstand extreme conditions, offering reliability and cost-effectiveness.

Why Choose Hangshun's Shale Shaker Screens?

Hangshun's screens combine advanced technology with practical design, offering several advantages:

- Customization: Available in multiple configurations to suit specific drilling conditions.

- Cost-Effectiveness: Durable construction reduces replacement frequency and maintenance costs.

- Global Compliance: Adherence to international standards ensures compatibility with global drilling equipment.

- Environmental Responsibility: Minimizes waste and fluid loss, supporting sustainable operations.

Conclusion

Shale shaker screens are a cornerstone of modern drilling operations, ensuring efficient solid control and fluid management. With Anping County Hangshun Wire Mesh Manufacture Co., Ltd.'s advanced shale shaker screen mesh solutions, operators can achieve optimal performance, durability, and compliance. Whether for oil extraction, environmental protection, or unconventional gas drilling, these screens deliver unmatched value.

For more information about shale shaker screen price, shale shaker screen china, or shale shaker screen factory services, visit Hangshun's official website.

References

1. National Institute of Standards and Technology (NIST) - Industry standards and technical guidelines for industrial equipment.

2. Anping County Hangshun Wire Mesh Manufacture Co., Ltd. - Product specifications and technical documentation.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025