- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen - Anping County Hangshun Wire Mesh Manufacture Co., Ltd | Advanced Drilling Fluid Separation, High Efficiency

Shale shaker screen mesh is a critical component in modern drilling operations, designed to separate solid cuttings from drilling fluids.

Introduction to Shale Shaker Screens

A shale shaker screen is a specialized mesh screen installed within shale shakers, serving as the primary filtration system for drilling fluids. These screens are engineered to capture solid particles while allowing excess mud to drain back into the system. The dual or triple-layered stainless steel wire cloth construction ensures high filtering accuracy, making them indispensable in the oil and gas industry.

When drilling operations generate cuttings, they become coated with drilling fluid. As these cuttings pass over the shale shaker screen, the screen's fine mesh traps the solids, while the liquid separates and returns to the mud tank. This process is vital for maintaining the efficiency of the drilling fluid system and reducing waste.

Key Features and Advantages

- High Strength and Bearing Capacity: Constructed from durable stainless steel or carbon steel, these screens withstand heavy loads and harsh drilling conditions.

- Superior Filtering Accuracy: The multi-layered design ensures precise separation of particles, even in challenging environments.

- Excellent Wear and Corrosion Resistance: Surface treatments like coatings enhance longevity, making them suitable for prolonged use in corrosive environments.

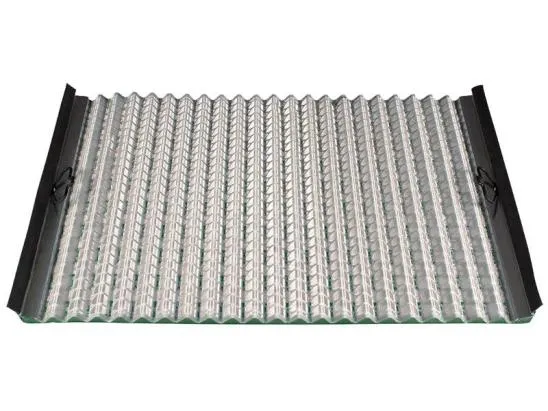

- High Processing Efficiency: Wave-shaped screens, for instance, optimize flow rates and reduce clogging risks.

- Flexibility and Adaptability: Available in various types (e.g., steel frame, composite frame, hook strip) to suit different shale shaker models and drilling conditions.

Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| Surface Treatment | Coating (black, green, blue, or custom colors) |

| Production Process | Weaving and perforating |

| Type | Steel frame, composite frame, hook strip, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in Drilling Operations

Shale shaker screens are widely used across multiple industries, including:

- Oil Drilling: Essential for separating cuttings from drilling mud in both onshore and offshore operations.

- Coal Bed Methane Drilling: Ensures efficient mud recycling in low-permeability formations.

- Shale Gas Extraction: Handles high-volume fluid separation in unconventional drilling projects.

- Environmental Protection: Used in river sludge treatment to purify contaminated water.

- Non-Excavation Horizontal Directional Drilling: Maintains fluid integrity during trenchless construction.

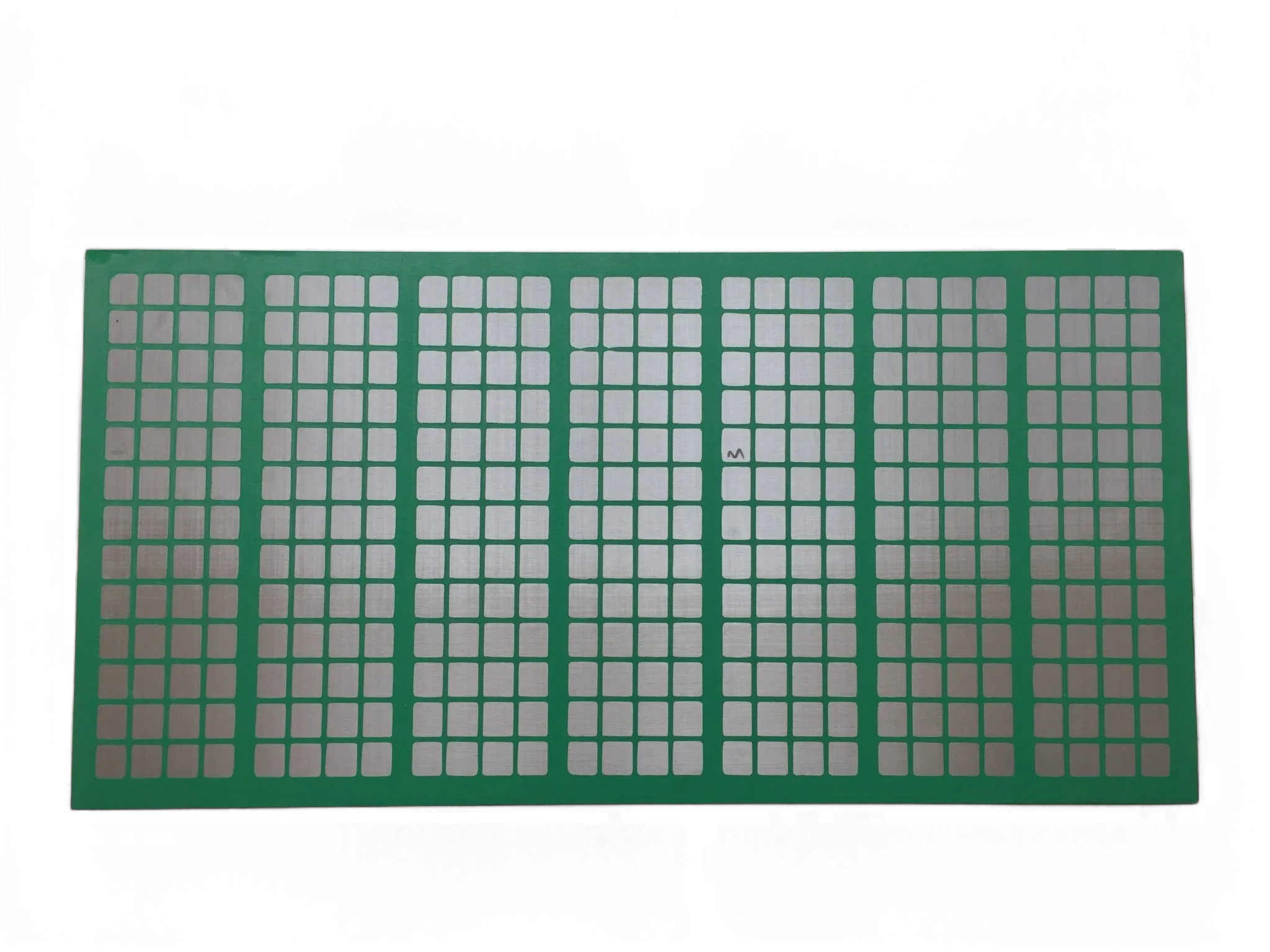

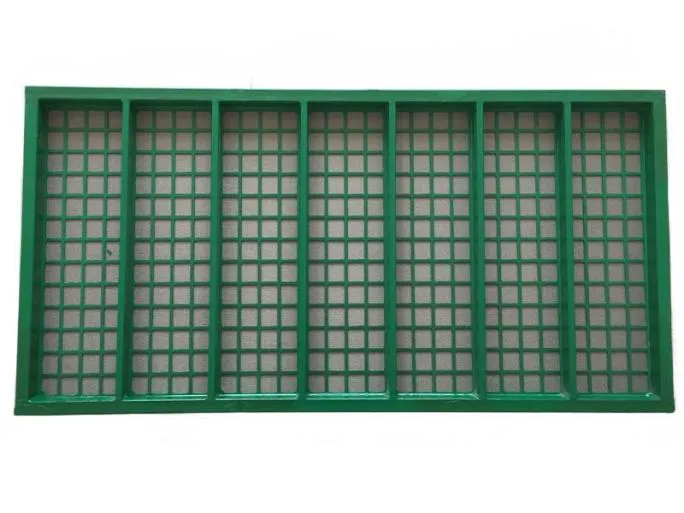

Steel frame shale shaker screens are designed for heavy-duty applications, offering maximum load-bearing capacity.

Types of Shale Shaker Screens

The product line includes several specialized types, each tailored for specific operational needs:

- Steel Frame Screens: Ideal for high-weight drilling fluid systems, providing structural stability.

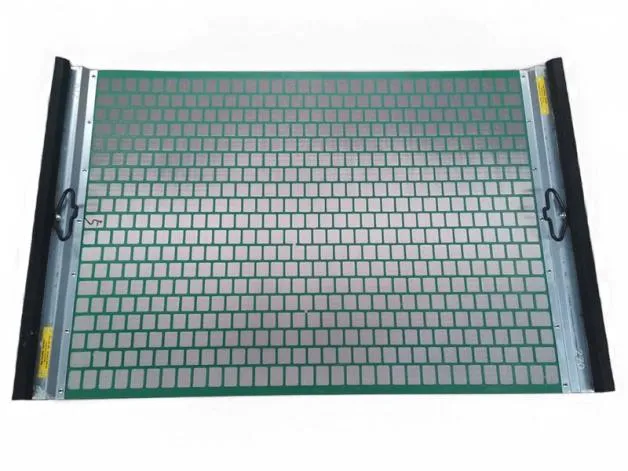

- Composite Frame Screens: Combine strength with lightweight properties, suitable for flexible shale shaker setups.

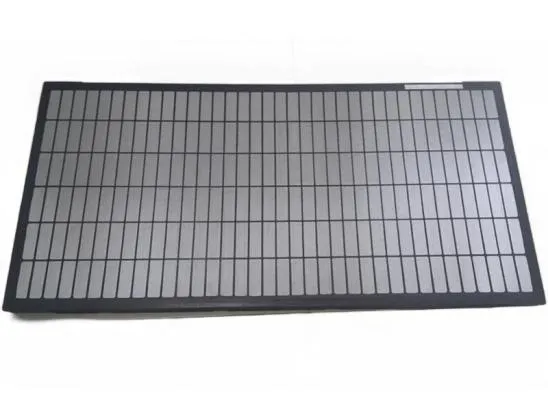

- Hook Strip Screens: Feature a unique design for easy installation and maintenance.

- Wave Screens: Optimized for maximum processing efficiency, reducing downtime caused by clogging.

Composite frame screens balance durability and flexibility, making them versatile for diverse drilling conditions.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Founded in 2005, Anping County Hangshun Wire Mesh Manufacture Co., Ltd is a leading manufacturer of industrial wire mesh products, specializing in shale shaker screens. Based in Hebei Province, China, the company has built a reputation for innovation, quality, and customer-centric solutions. With over 15 years of experience, Hangshun has supplied its products to clients across North America, Europe, and Asia, supporting critical drilling and environmental projects.

Hangshun adheres to international standards such as ISO 13501 and API RP 13C, ensuring that its products meet the highest quality benchmarks. The company's commitment to R&D has led to the development of advanced screen technologies, including multi-layered mesh systems and corrosion-resistant coatings.

Hook strip flat screens are designed for easy installation, reducing maintenance time and labor costs.

Why Choose Hangshun for Shale Shaker Screens?

Hangshun's shale shaker screens are engineered to deliver unmatched performance in demanding environments. Key advantages include:

- Customization: Tailored solutions for specific drilling conditions and equipment configurations.

- Quality Assurance: Rigorous testing and adherence to global standards ensure reliability.

- Cost-Effectiveness: High durability reduces replacement frequency, lowering long-term operational costs.

- Expert Support: Technical teams provide guidance on product selection and application.

Wave-shaped screens enhance processing efficiency, making them ideal for high-volume drilling operations.

Industry Standards and Compliance

Hangshun's products comply with critical industry standards, including:

- ISO 13501: Ensures safety and performance in industrial applications.

- API RP 13C: Sets guidelines for drilling fluid solids control systems.

- GBT 11648 and GBT 11650: Chinese national standards for wire mesh and filtration equipment.

These certifications validate the company's commitment to quality and safety, ensuring that its products meet the needs of global markets.

Wave screens are optimized for high-efficiency solids separation, reducing downtime and maintenance.

Environmental and Economic Impact

By improving the efficiency of drilling fluid recycling, Hangshun's shale shaker screens contribute to sustainable drilling practices. The reduction in waste and the reuse of drilling mud lower environmental footprints while cutting operational costs. According to a 2022 report by the National Institute of Standards and Technology (NIST), advanced filtration technologies like these can reduce drilling fluid waste by up to 30%, enhancing both economic and environmental outcomes.

Composite frame screens combine strength and flexibility, making them suitable for a wide range of drilling applications.

Conclusion

Shale shaker screens are a cornerstone of modern drilling operations, enabling efficient solids separation and fluid recycling. With their robust construction, advanced design, and compliance with global standards, Hangshun's shale shaker screens set a new benchmark for performance and reliability. Whether for oil drilling, environmental protection, or unconventional gas extraction, these screens are essential tools for achieving operational excellence.

Steel frame screens are engineered for durability, making them ideal for heavy-duty drilling environments.

References

National Institute of Standards and Technology (NIST) (2022). "Advancements in Drilling Fluid Filtration Technologies." Retrieved from https://www.nist.gov/

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025