- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

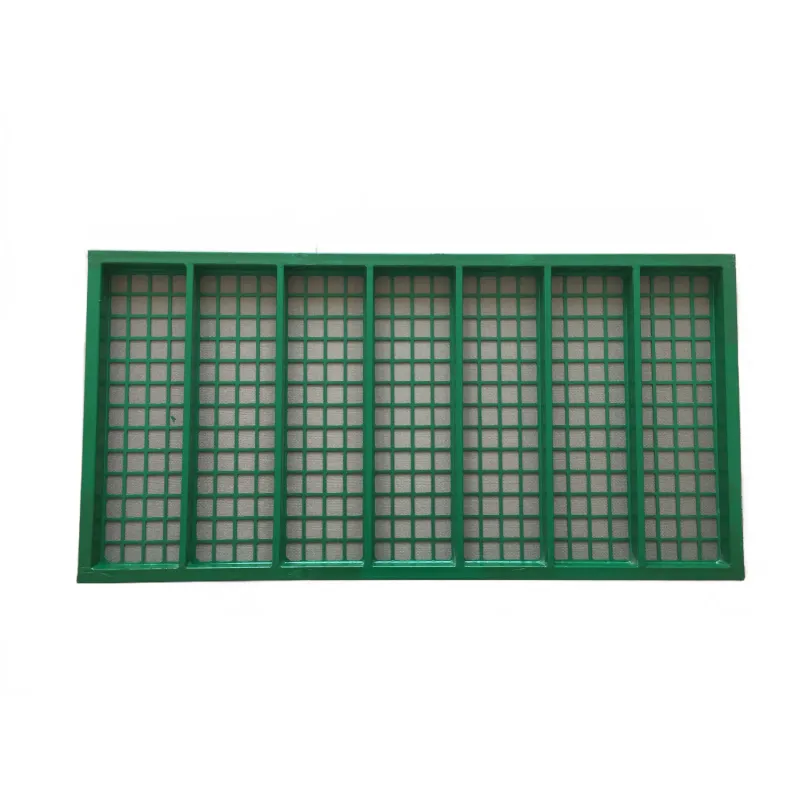

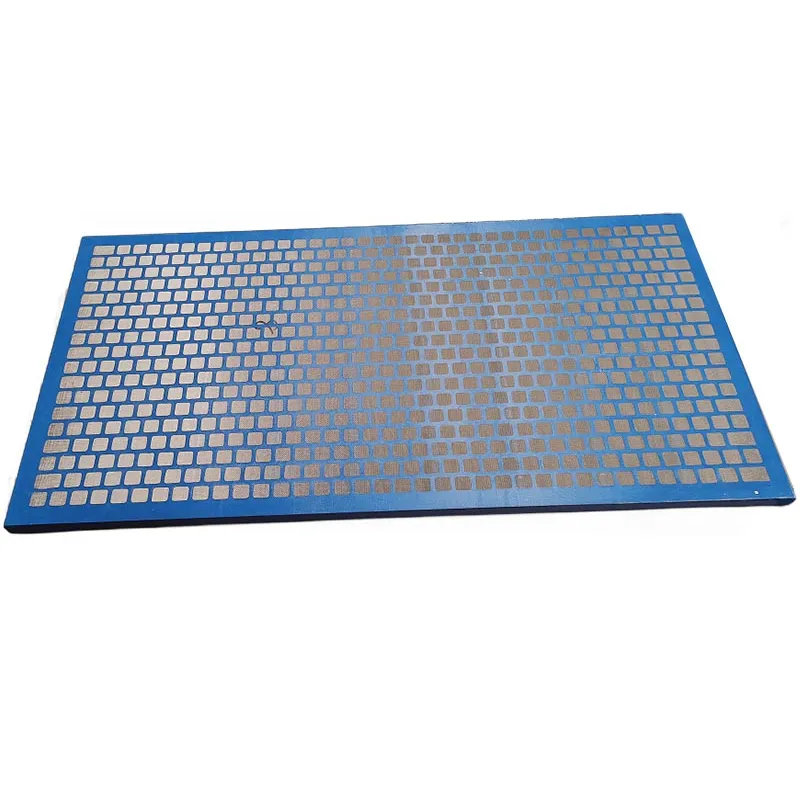

Shaker Screen for Sale – Durable, API-Rated, Fast Shipping

Steel Frame Shale Shaker Screen — real-world notes and a buyer’s guide

If you’re scanning the market for a Shaker Screen For Sale, you’ve probably noticed the chatter: composites are trendy, but steel-frame screens still carry the day on hot, high-G rigs. Coming out of the Industrial Zone, South of Anping Town, Hengshui (Hebei, China), this Steel Frame Shale Shaker Screen is built on familiar territory—the mesh capital—and that matters more than it sounds.

What’s trending on rigs (and HDD yards)

We’re seeing finer API designations and tighter solids control targets—less dilution, more mud recirculation. In fact, many customers say steel frames retain shape under thermal cycling better than some composites. Meanwhile, buyers want API RP 13C labels, traceability, and consistent conductance—no surprises during night shift. Sustainability is creeping in too: longer service life means fewer pallets on the road.

Core specs at a glance

| Frame | Cold‑rolled steel, welded ribs, epoxy sealed |

| Screen cloth | 304/316 SS multi-layer (2–3 plies), pre-tensioned |

| API designation | API 20–325 compliant (API RP 13C, D100 verified) |

| Conductance | ≈0.9–6.0 kd/mm (real‑world use may vary) |

| Common sizes | 585×1165 mm, 635×1253 mm, 697×1050 mm; custom fits available |

| Seal/gasket | NBR or PU perimeter, anti-leak corners |

| Service life | ≈350–700 circulating hours (WBM/OBM, solids load dependent) |

How it’s made (short version)

- Materials: 304/316 SS mesh, Q235/Q345 steel frame, oil‑resistant adhesive.

- Process: frame welding → sandblast → epoxy coat → mesh pre‑tensioning → bonding → curing → gasket fit.

- Testing: API RP 13C (D100, conductance), ASTM D3359 adhesion, visual flatness checks, salt spray on coated parts (ASTM B117, when specified).

Typical data from a recent run: API 170 screen measured D100 ≈ 87 μm, conductance ≈ 2.1 kd/mm, open area ≈ 32%. That’s solid for mid‑fine cuttings control.

Where it fits

Oil & gas drilling shakers, HDD and trenchless, workover, and certain mining tailings lines. Compatible options for MONGOOSE/MEERKAT, FLC 500/2000, King Cobra/LCM, and similar—ask for the model cross‑list if you’re mixing fleets. To be honest, that saves hours.

Why steel-frame here?

- Rigid support under high Gs; keeps cloth tension even.

- Predictable repairability (field patches stick better on clean epoxy).

- Good value: cost/hour tends to be competitive against composites in hot OBM.

Vendor snapshot (quick compare)

| Vendor | API RP 13C Label | OEM Fit Range | MOQ | Lead Time | Price Level |

|---|---|---|---|---|---|

| HF Petro Mesh (Anping) | Yes, per screen | Derrick, NOV, M‑I, etc. | 10–20 pcs | 7–15 days ≈ | Mid |

| Composite‑only Brand | Yes | Selected series | 20–50 pcs | 10–25 days | Mid‑High |

| Generic Importer | Sometimes | Limited | Varies | 15–30 days | Low |

Customization and proof

Options: mesh layering, side seal material, hookstrip vs. frame, marking, and palletization for offshore. Certifications available: ISO 9001 manufacturing scope; material certs on request. API RP 13C test sheets accompany batches—keeps auditors happy.

Case note (Middle East land rig): switching to API 140/170 stack from this line cut dilution 12–15%, with screen life rising from ≈320 h to ≈520 h in WBM. Crew feedback: “less blinding after bottoms up,” which, honestly, is what you want at 3 a.m.

Should you buy?

If you need a rugged, API‑labeled steel option with predictable QC, this line is a safe bet. For quick quotes on a Shaker Screen For Sale, send the shaker make/model and desired API range. For HDD yards, request the tougher gasket spec—it’s worth it.

Citations:

- API RP 13C: Recommended Practice on Drilling Fluids Processing Systems.

- ASTM E11: Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9001: Quality Management Systems — Requirements.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025