- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

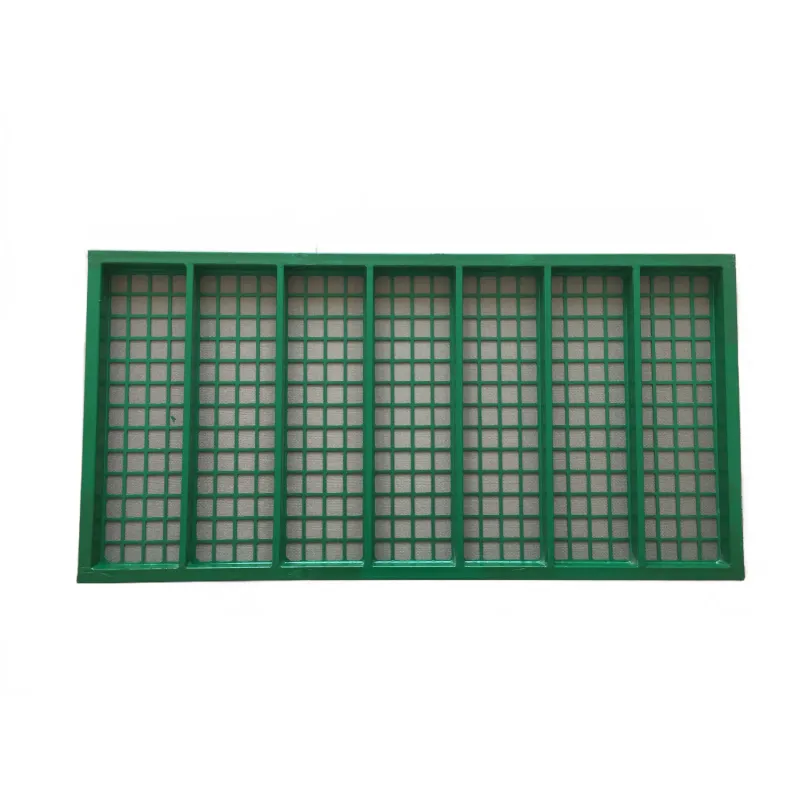

Shaker Screen for Sale - Durable, API Compliant, Fast Ship

Steel Frame Shale Shaker Screen — What’s actually moving the market

If you’ve been around rigs or HDD spreads lately, you’ve probably noticed buyers asking very specific questions about cut point, conductance, and service hours. It’s not hype; operating costs are under the microscope. That’s why I took a closer look at a Shaker Screen For Sale coming out of Anping—the long-time wire-mesh hub in Hebei, China. To be honest, I expected a typical catalog pitch. What I found was more interesting.

Quick take on industry trends

- API RP 13C labeling is now a must-have; buyers are verifying conductance and D100 data.

- Higher solids loading from aggressive drilling programs is pushing multi-layer meshes and smarter bonding methods.

- ESG pressure means more mud recycling and less waste—screens carry more of the load.

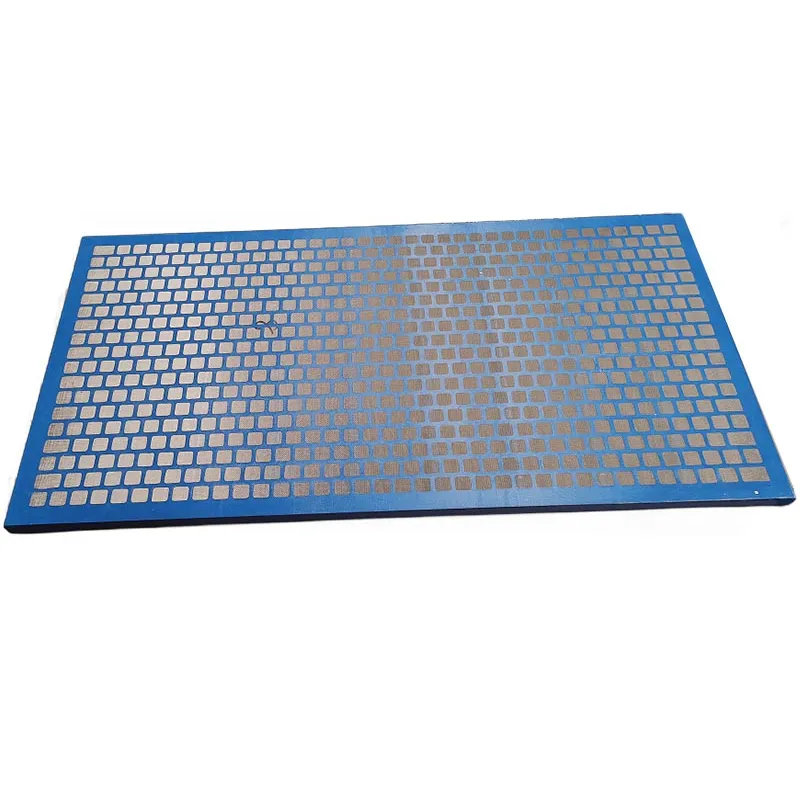

Product snapshot: Steel Frame Shale Shaker Screen

Origin: Industrial zone, South of Anping Town, Hengshui, Hebei, China. The build? Rigid steel frame, pre-tensioned SS wire cloth, and epoxy bonding with spot-weld reinforcement. In practice, that combo resists wave-flex fatigue better than many budget imports, at least from what crews tell me.

Specs that matter

| Model | Steel Frame Shale Shaker Screen |

| API designation | API 60–230 (≈; real-world use may vary) |

| Mesh layers | 2–4 layers (SS304/SS316) |

| Open area | ≈40–58% |

| Conductance | 0.4–2.1 kD/mm (API RP 13C test) |

| Common size | 1165 × 585 mm and custom |

| Frame & bonding | Powder-coated steel, epoxy + spot welds |

| Service life | ≈300–700 hours depending on mud properties |

| Compatibility | Fitments available for common shakers (verify model) |

| Certifications | Factory ISO 9001:2015; API RP 13C test labeling |

Applications: oil & gas drilling, HDD/trenchless, geothermal, mining tailings, and even waterwell on tougher formations.

Process flow, materials, and testing

- Materials: SS304/SS316 woven wire (ISO 9044), Q235 steel frame, NBR/PU gasket.

- Methods: mesh pre-tensioning, layered lamination, epoxy bonding, heat cure, flatness correction.

- Testing: API RP 13C conductance & D100; sieve compliance per ASTM E11; salt-spray per ASTM B117 (72 h typical); peel/bond test; frame flatness ≤±1.5 mm.

Why crews pick it

- Solid conductance-to-life balance; screens don’t blind as fast on weighted mud.

- Steel frame handles aggressive G-forces without the “banana bow.”

- Reliable API labeling—many customers say the cut is what it says on the tin.

Vendor comparison (field-notes level)

| Vendor Type | Price | API 13C Evidence | Customization | Lead Time | Warranty |

|---|---|---|---|---|---|

| Anping specialist (this product) | Competitive | Test sheets provided | Size, mesh, branding | 7–15 days (typ.) | Manufacturing defects |

| Generic import | Low | Inconsistent | Limited | Variable | Minimal |

| Premium OEM | High | Full documentation | Broad | Stock on common sizes | Strong |

Mini case study

West Asia land rig, API 120 screens. Weighted WBM at 1.25–1.32 sg, ROP 18–22 m/hr. After swapping in these steel-frame screens: average life rose from ≈360 h to ≈520 h; screen deck discard dropped ≈12% by weight; shaker motor amps stabilized (less blinding). Operator feedback: “Fewer changeouts, especially on night shift.” Results will vary, but it tracks with what I’ve seen elsewhere.

Customization

Options include private-label printing, color-coded frames, special mesh stacks for troublesome clays, and bespoke sizes to match legacy shakers. Just share mud properties, target API cut, and shaker model.

Shaker Screen For Sale highlights: documented API RP 13C tests, stable conductance, and practical lead times from a factory that’s clearly set up for repeatability rather than one-off batches. If you need a sample lot for a trial well, ask for the test sheets—saves time arguing about D100 later.

References

- API RP 13C: Recommended Practice on Drilling Fluids Processing Systems Evaluation.

- ISO 9001:2015 — Quality management systems — Requirements.

- ASTM E11 — Standard Specification for Woven Wire Test Sieve Cloth.

- ISO 9044 — Industrial woven wire cloth — Technical requirements and tests.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025