- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Premium Shale Shaker Screens: Optimal Solids Control & Durability

FILTECH Spotlight: Unveiling China's Leading Manufacturers in Mud Vibrating Screens and Steel Gratings

The global industrial landscape is continuously evolving, demanding increasingly sophisticated and efficient solutions for filtration, separation, and structural integrity. At the forefront of this evolution stands FILTECH, the world's largest and most important event for filtration and separation, serving as a critical nexus for innovation, technology exchange, and strategic partnerships. For B2B decision-makers seeking the cutting edge in industrial filtration, particularly in the realm of mud vibrating screens (commonly known as shale shaker screens) and steel gratings, FILTECH offers an unparalleled opportunity to connect with leading manufacturers and suppliers.

China, in particular, has emerged as a powerhouse in these sectors, with its manufacturers consistently pushing boundaries in material science, engineering precision, and cost-effectiveness. The nation's advanced manufacturing capabilities are providing robust, high-performance solutions that are reshaping industries from oil & gas to water treatment, and from mining to construction. This article delves into why Chinese manufacturers of shale shaker screen mesh and steel grating are gaining significant global attention, and highlights key players driving this innovation, including an in-depth look at Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

Industry Trend Spotlight: The Evolution of Filtration and Grating Solutions

The demand for high-performance industrial filtration media and robust structural gratings is surging, driven by several key global trends. The development of sophisticated, high-performance filtration media is critical for industries facing stricter environmental regulations and complex processing challenges. Concurrently, the need for custom-engineered mesh solutions tailored for specific, often extreme, applications is gaining paramount importance. Manufacturers are increasingly focusing on enhancing shale shaker screen material to ensure superior corrosion resistance and high-temperature performance, particularly in demanding environments like deep-sea drilling or chemical processing. Furthermore, the adoption of advanced manufacturing techniques for complex filter elements and gratings is enabling greater precision, durability, and efficiency.

Market Dynamics and Growth Drivers

The market for industrial filtration and separation, encompassing products like shale shaker screens and steel gratings, is experiencing steady growth. This expansion is primarily fueled by increasing industrialization across emerging economies, more stringent global environmental regulations mandating cleaner discharges and resource recovery, and rising demand from critical sectors such as petrochemical, water treatment, and pharmaceutical industries. There's a particular emphasis on high-efficiency and durable filtration systems that can withstand harsh operational conditions while minimizing downtime and operational costs.

Emerging Focus Areas

- Sustainable Filtration: A growing imperative for solutions that reduce waste, conserve energy, and allow for easier material recovery and recycling.

- Advanced Materials: Development and application of new alloys, composites, and coatings for extreme conditions, extending the lifespan and performance of shale shaker screens for sale and gratings.

- Energy-Efficient Separation Technologies: Innovations aimed at reducing the energy consumption associated with filtration and separation processes.

- Custom-Engineered Mesh Solutions: The ability to design and produce highly specialized shale shaker screen mesh and gratings that meet unique operational parameters.

- Smart Process Optimization: Integration of sensors and data analytics to monitor filtration performance in real-time, enabling predictive maintenance and optimized operations.

Profiles of Leading Manufacturers: Innovation from China and Beyond

At FILTECH, a diverse range of companies showcase their prowess in filtration and separation. Among the most impactful are those specializing in shale shaker screen technology and steel gratings, with China's manufacturing sector making significant strides.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd (China)

As a prominent name among shale shaker screen manufacturers from China, Anping County Hangshun Wire Mesh Manufacture Co., Ltd stands out for its unwavering commitment to quality and innovation in industrial wire mesh and sintered filter elements. Specializing in high-performance solutions, they are a trusted shale shaker screen supplier for some of the most demanding industries.

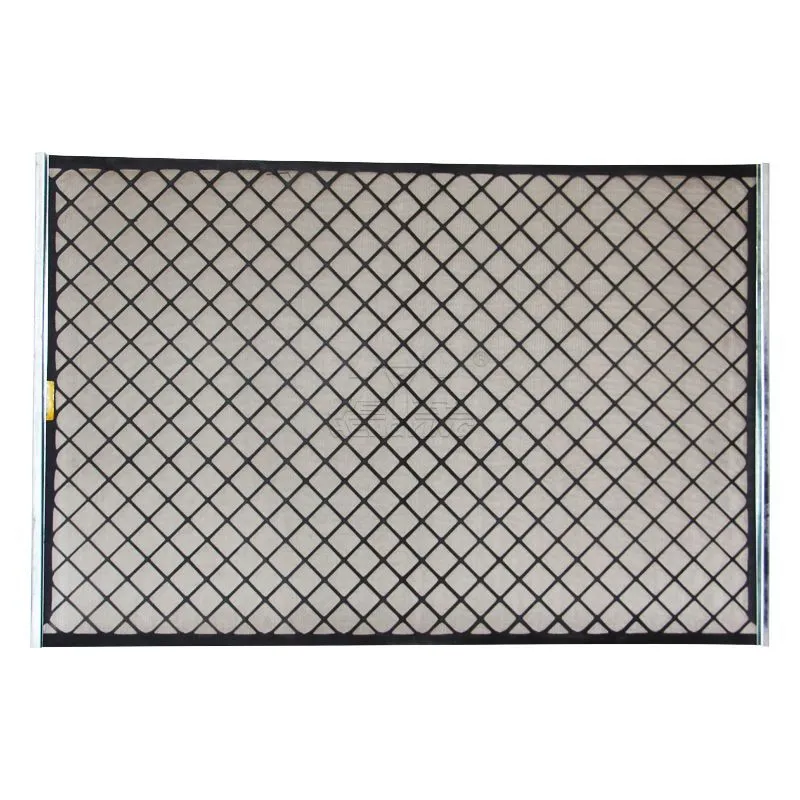

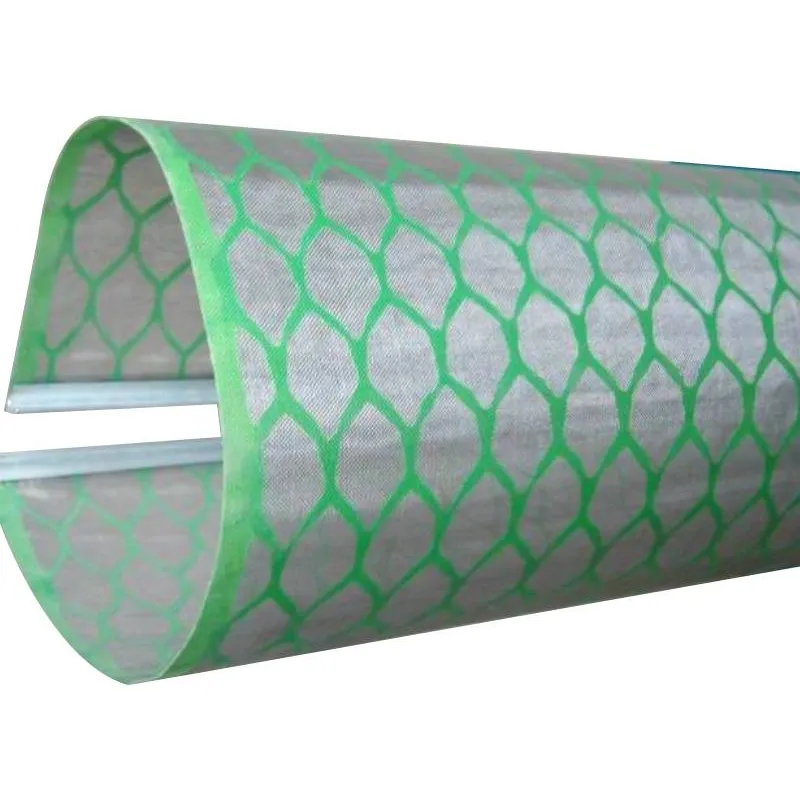

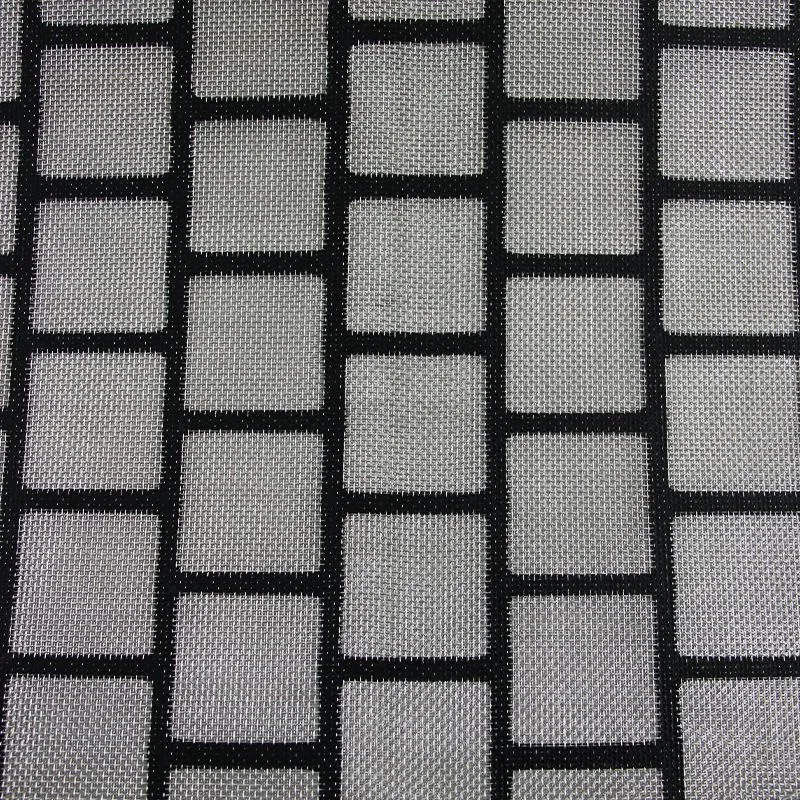

Their expertise lies in producing robust shale shaker screens engineered for optimal fluid control and solids separation in drilling operations. The company's focus extends beyond standard products, offering extensive custom fabrication capabilities to meet highly specific client requirements, whether it's for unique shale shaker screen mesh sizes, specialized shale shaker screen material compositions, or particular structural designs for steel gratings. Their commitment to material science ensures that their products deliver superior filtration efficiency, extended operational life, and excellent resistance to wear and tear.

With a strong application focus on demanding sectors like oil & gas, chemical processing, mining, and water treatment, Anping County Hangshun Wire Mesh Manufacture Co., Ltd consistently delivers solutions that enhance operational efficiency and reduce maintenance costs. Their reputation as a reliable shale shaker screen factory in China is built on stringent quality control, advanced production techniques, and a deep understanding of industry challenges. For those seeking competitive shale shaker screen price without compromising on quality, they represent a premier choice among shale shaker screen suppliers.

To explore their range of high-quality products, including their innovative hook strip soft screens, visit their product page: Hook Strip Soft Screen.

Other Noteworthy Global Players

- GKD – Gebr. Kufferath AG (Germany): A world leader in woven metal meshes and technical fabrics, GKD offers innovative solutions for industrial filtration, process belts, and architectural meshes, known for precision engineering and high-performance materials.

- Sefar AG (Switzerland): Specializing in precision fabrics and components for filtration and screen printing, Sefar's products are crucial in fine particle separation and are valued for their exceptional quality and reliability across various industries.

- Bopp & Co. AG (Switzerland): With a long history in wire weaving, Bopp manufactures high-quality wire mesh, filter elements, and screens, serving demanding applications from pharmaceuticals to aerospace, emphasizing customization and technical expertise.

- W. S. Tyler, Inc. (USA): A pioneer in the field of industrial sieving and screening, W.S. Tyler provides a comprehensive range of test sieves, wire mesh, and screening media, known for accuracy and durability in particle analysis and separation.

- Cambridge Engineered Solutions (USA): As a leading global provider of metal conveyor belts and wire mesh products, Cambridge offers innovative solutions for high-temperature, heavy-duty, and precision applications across food processing, heat treating, and more.

Market Outlook & Opportunities: Navigating Tomorrow's Demands

The future for mud vibrating screen and steel grating manufacturers is dynamic and full of opportunities. Buyer demand is increasingly shifting towards solutions that offer not just superior performance but also enhanced sustainability, greater energy efficiency, and adaptability to evolving operational challenges.

Upcoming trends highlight a pronounced move towards automation in material handling and filtration processes, requiring screens and gratings that integrate seamlessly with automated systems. Smart manufacturing principles are also gaining traction, where filtration systems are equipped with sensors for real-time monitoring and predictive maintenance, optimizing performance and reducing manual intervention.

Furthermore, the imperative for sustainability continues to shape product development. This means a greater emphasis on products with longer lifespans, made from recyclable materials, and designed for minimal environmental impact. Manufacturers who can deliver on these fronts, offering durable, efficient, and eco-conscious shale shaker screens for sale and steel gratings, will be exceptionally well-positioned for growth.

Chinese manufacturers, with their strong R&D investments and robust supply chains, are uniquely poised to capitalize on these trends, providing innovative solutions at competitive shale shaker screen price points, without compromising on quality or performance.

Buyer/Business Takeaways: Strategic Investment in Filtration & Grating Solutions

Why Investing in High-Quality Mud Vibrating Screens and Steel Gratings Makes Sense

For B2B decision-makers, investing in high-quality mud vibrating screens (shale shaker screens) and industrial steel gratings is not merely an operational necessity; it's a strategic investment that yields substantial returns. Superior shale shaker screens ensure efficient solids control, reducing drilling fluid costs, minimizing waste, and protecting downstream equipment. Durable steel gratings provide safe, long-lasting, and structurally sound platforms and walkways, crucial for operational safety and regulatory compliance. Opting for products from reputable shale shaker screen suppliers means enhanced performance, reduced downtime, and lower overall maintenance costs.

Tips for Adopting or Partnering with Chinese Manufacturers

- Prioritize Quality and Certifications: Look for shale shaker screen manufacturers with international quality certifications (e.g., ISO) and a proven track record of delivering consistent product quality.

- Seek Customization Capabilities: Many Chinese factories, like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, excel at custom engineering. Leverage this to get solutions perfectly tailored to your specific application requirements.

- Evaluate Technical Support & After-Sales Service: A strong partnership involves not just product delivery but also reliable technical support and after-sales service.

- Competitive Pricing: While the shale shaker screen price from Chinese shale shaker screen suppliers can be highly competitive, ensure you're comparing value, not just cost. Quality and longevity are key.

- Visit and Verify: Whenever possible, conduct factory audits or engage third-party inspection services to verify capabilities and quality control at the shale shaker screen factory in China.

Future-Proof Strategies

To future-proof your operations, consider partnerships that emphasize R&D, continuous material innovation (e.g., advanced shale shaker screen material), and integrated smart technologies. Invest in modular and adaptable solutions that can evolve with your operational needs and regulatory changes. Building long-term relationships with reliable shale shaker screen suppliers from China can provide a stable and innovative supply chain, crucial for sustained competitive advantage.

Conclusion

FILTECH remains an indispensable platform for understanding and shaping the global mud vibrating screen and steel grating markets. The event highlights the critical innovations driving efficiency, sustainability, and performance across industries worldwide. Chinese manufacturers, exemplified by Anping County Hangshun Wire Mesh Manufacture Co., Ltd, are pivotal in this narrative, offering high-quality, custom-engineered solutions at competitive shale shaker screen price points that meet the rigorous demands of modern industrial applications.

For B2B decision-makers seeking advanced shale shaker screens for sale and other high-performance wire mesh products, exploring the capabilities of these leading Chinese shale shaker screen manufacturers is a strategic imperative.

Visit Anping County Hangshun Wire Mesh to Learn More-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025