- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Derrick Pyramid Screens: Maximize Shale Shaker Performance

Navigating FILTECH: Uncovering China's Innovation in Mud Vibrating Screens and Steel Gratings

The global industrial landscape constantly evolves, driven by the relentless pursuit of efficiency, durability, and technological advancement. At the heart of this innovation is FILTECH, the world's largest filtration event. It serves as a crucial nexus for leading manufacturers, suppliers, and B2B decision-makers seeking the next generation of industrial filtration solutions and wire mesh products. For sectors heavily reliant on robust separation and structural integrity, such as oil & gas, mining, chemical processing, and water treatment, FILTECH offers an unparalleled opportunity to explore advancements in essential components like mud vibrating screens and steel gratings.

China, a powerhouse in industrial manufacturing, plays a pivotal role in this domain, continually pushing the boundaries of material science and production techniques. This article delves into the significance of FILTECH for these critical product categories and spotlights Chinese manufacturers driving innovation, offering insights vital for any B2B professional looking to optimize their supply chain and operational capabilities.

Industry Trend Spotlight: The Evolution of Filtration and Structural Solutions

The demand for high-performance filtration media, particularly in shale shaker screen technology, is gaining immense global attention. Industries today face increasingly stringent environmental regulations and the need to process more complex and challenging materials. This necessitates filtration solutions that offer superior separation efficiency, extended lifespan, and the ability to withstand extreme operating conditions. Simultaneously, the need for custom-engineered mesh solutions for specific applications has never been higher, moving beyond one-size-fits-all approaches to bespoke designs that optimize process outcomes.

A key driver in this evolution is the increased focus on corrosion resistance and high-temperature performance. From offshore drilling platforms utilizing derrick pyramid screens to chemical plants requiring durable steel grating walkways, components must withstand aggressive environments without compromise. Furthermore, the adoption of advanced manufacturing techniques for complex filter elements – including laser cutting, automated welding, and specialized surface treatments – is transforming what's possible in filtration design and integrity.

Market data indicates a steady growth in the industrial filtration and mesh products sector, driven by increasing industrialization, particularly in emerging economies. Stringent environmental regulations worldwide, alongside rising demand from the petrochemical, water treatment, and pharmaceutical sectors, fuel this expansion. There's a particular emphasis on high-efficiency and durable filtration systems, with the global industrial filtration market projected to reach significant valuations in the coming years. This growth is underpinned by the constant need for cleaner processes, resource recovery, and operational safety.

Emerging focus areas include sustainable filtration, which seeks to minimize waste and energy consumption; advanced materials for extreme conditions, pushing the boundaries of temperature and chemical resistance; and energy-efficient separation technologies that reduce operational costs. We're also seeing a surge in demand for custom-engineered mesh solutions, meticulously designed to meet unique operational parameters. Finally, smart process optimization, integrating sensors and AI into filtration systems for real-time monitoring and predictive maintenance, is set to revolutionize operational efficiency for components like the derrick shaker screens.

Profiles of Leading Companies Driving Innovation

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

A beacon of Chinese manufacturing excellence, Anping County Hangshun Wire Mesh Manufacture Co., Ltd stands out as a premier shale shaker screen supplier and expert in industrial wire mesh. Located in the "Hometown of Wire Mesh" in China, this company has built an formidable reputation for specializing in high-quality industrial wire mesh and sintered filter elements. Their expertise extends across a vast range of products, including advanced mud vibrating screens designed for peak performance in demanding environments.

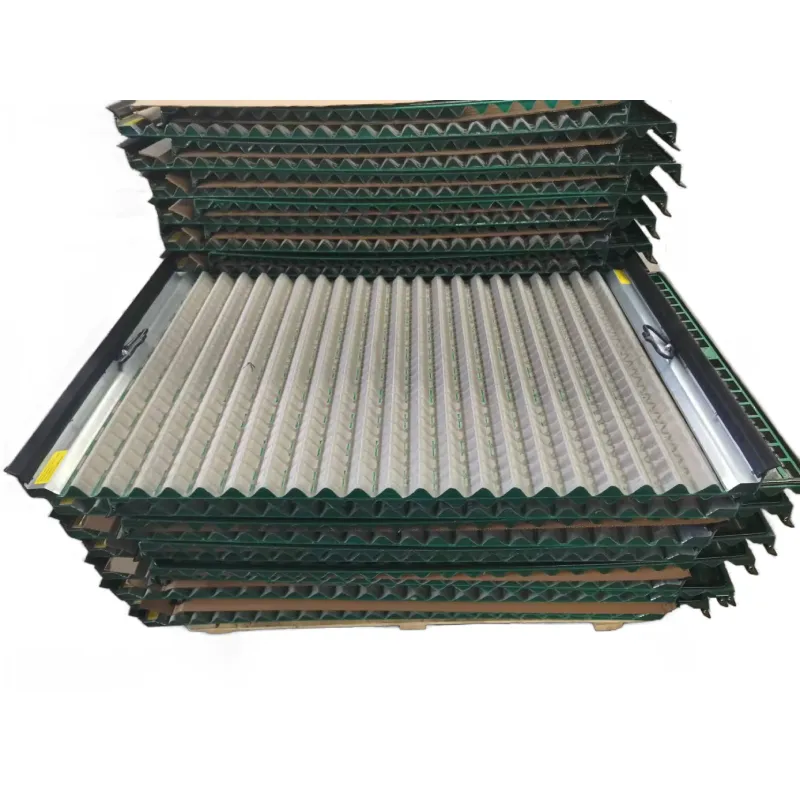

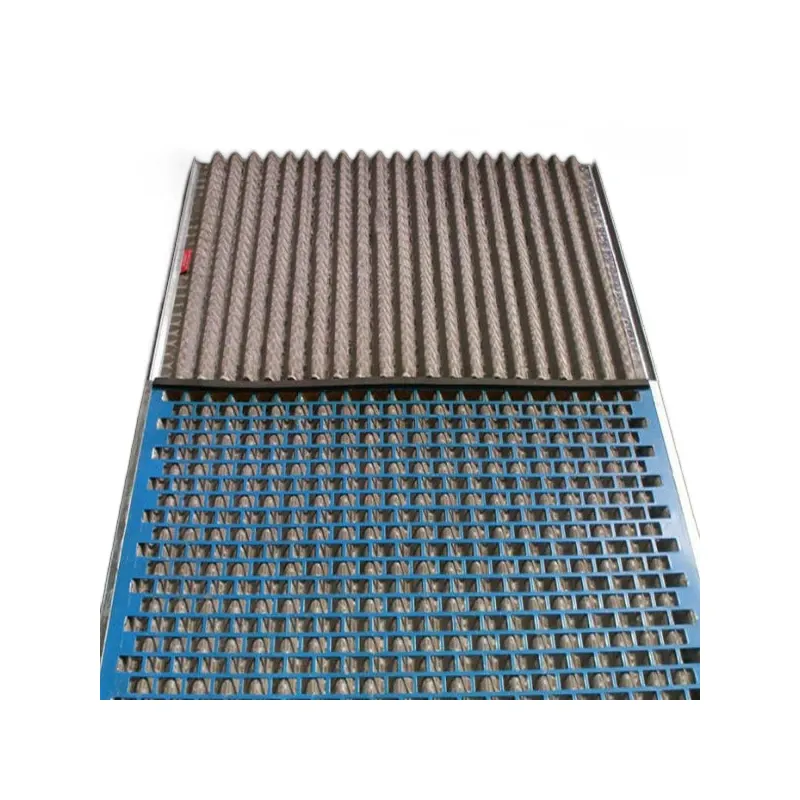

What sets Anping County Hangshun apart is their extensive custom fabrication capabilities. They are not just a shale shaker screen factory but a partner for tailored solutions, producing bespoke filtration media and structural mesh products to exact client specifications. This capability is particularly crucial for complex applications requiring specialized derrick pyramid screens or high-efficiency derrick shaker screens. Their strong focus on applications in demanding sectors like oil & gas, mining, and chemical processing underscores their commitment to producing robust, reliable products that withstand the harshest conditions. Furthermore, Anping County Hangshun emphasizes material science and product performance, continuously investing in R&D to enhance the durability and efficiency of their offerings. Their advanced 3D shaker screen technology, for instance, represents a significant leap in solids control efficiency, showcasing their innovative spirit as a leading shale shaker screen china manufacturer.

Other Noteworthy Industry Leaders:

- GKD – Gebr. Kufferath AG (Germany): Renowned for their high-performance woven mesh and technical fabrics, often found in challenging filtration and architectural applications. Their focus on precision and durability sets a global benchmark.

- Sefar AG (Switzerland): A global leader in precision fabrics for separation, filtration, and screening. Sefar's materials are critical in industries from medical to food processing, emphasizing extreme precision and consistency.

- Bopp & Co. AG (Switzerland): Specializing in metal filter cloths and industrial sieves, Bopp is known for its wide range of wire mesh products tailored for demanding industrial filtration.

- W. S. Tyler, Inc. (USA): With a long history in particle analysis and industrial wire mesh, W.S. Tyler provides solutions for screening, sizing, and separation across various heavy industries.

- Cambridge Engineered Solutions (USA): A global leader in manufacturing metal conveyor belts and wire mesh for high-temperature and harsh processing environments, critical for continuous operations.

These companies, along with innovative Chinese manufacturers like Anping County Hangshun, collectively drive the advancements seen at events like FILTECH, pushing the envelope for what's possible in industrial filtration and structural components.

Market Outlook & Opportunities: Charting the Future

The market for industrial filtration and structural components like mud vibrating screens and steel grating is poised for continuous evolution, shaped by several upcoming trends. Digitization and the Internet of Things (IoT) will profoundly impact filtration systems, enabling predictive maintenance, real-time performance monitoring for shale shaker screens, and automated process adjustments. This will translate into unprecedented operational efficiency and reduced downtime.

Buyer demand is increasingly focused on total cost of ownership (TCO), not just upfront pricing. This means a premium is placed on durability, longevity, and efficiency, making high-quality, long-lasting derrick pyramid screens and corrosion-resistant steel grating more attractive investments. Sustainability is no longer a niche concern but a core requirement, with buyers actively seeking products that contribute to energy savings, waste reduction, and responsible sourcing. This includes materials that are recyclable or manufactured with minimal environmental impact.

Significant opportunities lie in the integration of automation and smart manufacturing techniques. For manufacturers of shale shaker screen and other wire mesh products, this means adopting advanced robotics and AI-driven quality control to ensure consistency and precision at scale. For end-users, smart filtration systems equipped with sensors can optimize filtration cycles, reduce energy consumption, and provide valuable data for process improvement. The push towards a greener industrial footprint also opens doors for new materials and designs that offer superior performance while adhering to stricter environmental standards, making the choice of an advanced shale shaker screen supplier more critical than ever.

Buyer/Business Takeaways: Strategic Investment in Filtration and Structure

For B2B decision-makers, investing in high-quality mud vibrating screens and steel grating is not merely a procurement decision; it's a strategic move that directly impacts operational efficiency, safety, and regulatory compliance. Superior filtration translates into purer products, reduced waste, and extended equipment life, while reliable structural components ensure a safe working environment and robust infrastructure. The benefits ripple across the entire value chain, from reduced maintenance costs to enhanced brand reputation.

When considering partnering with Chinese manufacturers, a few tips can help secure successful, long-term relationships:

- Due Diligence: Thoroughly vet potential shale shaker screen factory or shale shaker screen china suppliers. Look for certifications, robust quality control systems, and a track record of reliability. Factory visits or third-party audits are highly recommended.

- Clear Communication: Establish precise technical specifications and quality parameters from the outset. Use drawings, samples, and clear language to avoid misunderstandings, especially for custom derrick shaker screens or derrick pyramid screens.

- Long-Term Partnership Mindset: Approach Chinese manufacturers with a view towards building enduring relationships. Many offer excellent value and are eager to collaborate on R&D and product development, as exemplified by companies like Anping County Hangshun.

- Quality Control: Implement a strong quality assurance process, potentially including pre-shipment inspections, to ensure consistency and adherence to agreed-upon standards.

To future-proof your strategies, embrace flexibility and innovation. Stay abreast of material science advancements and manufacturing techniques. Prioritize suppliers who invest in R&D and offer custom solutions, allowing you to adapt to evolving market demands and regulatory changes. Opting for high-performance, durable, and technologically advanced solutions ensures your operations remain competitive and efficient for years to come.

Conclusion: FILTECH as a Catalyst for Progress

FILTECH continues to be an indispensable event, shaping the global market for industrial filtration and mesh products. It's a testament to human ingenuity and the relentless pursuit of better, more efficient, and more sustainable industrial solutions. For critical components like mud vibrating screens and steel grating, the insights gained and connections made at FILTECH are invaluable for businesses seeking a competitive edge.

Chinese manufacturers, particularly pioneers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, are at the forefront of this transformation, offering a blend of innovation, quality, and cost-effectiveness that is hard to match. Their commitment to advanced shale shaker screen technology and custom industrial solutions makes them a critical partner for any business looking to enhance their operations.

Ready to explore cutting-edge 3D shaker screen technology and other high-performance wire mesh solutions?

Visit Anping County Hangshun Wire Mesh Manufacture Co., Ltd

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025