- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Need Welded Bar Grating that's Strong, Anti-Slip & Custom?

Welded Steel Grating: practical notes from the field

If you’re specifying welded bar grating for stairs, catwalks, or trench covers, here’s the short version: materials and finish matter as much as load tables. I’ve walked enough plants to see what lasts. This product comes out of the industrial zone south of Anping, Hebei — a region that basically breathes metalwork — and, to be honest, the manufacturing maturity shows.

What’s trending

Across petrochemical, water treatment, and power generation, buyers are leaning toward serrated, hot-dip galvanized panels, tighter cross-bar pitch for smaller-wheeled carts, and pre-banded edges to cut install time. Surprisingly, sustainability questions now pop up in RFQs: zinc coating mass, service-life expectation, and recyclability.

How it’s made (quick process flow)

Materials: mild steel bearing bars (ASTM A36 or ASTM A1011), cross bars (usually twisted square or round).

Methods: resistance welding under pressure (consistent fusion ≈ full contact), optional serration milling, then cutting, banding, toe-plate/nosing, and final QC.

Finishes: black steel, primer/paint, or hot-dip galvanizing per ASTM A123 / ISO 1461.

Testing: load/deflection to NAAMM MBG 531; coating thickness checks; dimensional tolerances; slip resistance where required (site tests vary). Real-world deflection at 1.0 m span under 5 kN/m² is typically ≈ 3–5 mm, within 1/200–1/240 span for common sizes (your mileage will vary).

Service life: black steel ≈ 3–7 years outdoors; painted ≈ 5–10; galvanized ≈ 20–30 depending on environment and maintenance.

Product snapshot (specs)

| Product | Welded Steel Grating |

| Bearing bar sizes | 25×3 to 50×5 mm (others on request) |

| Bar spacing (center-to-center) | 30, 34.3, 40 mm common; cross bar 50 or 100 mm |

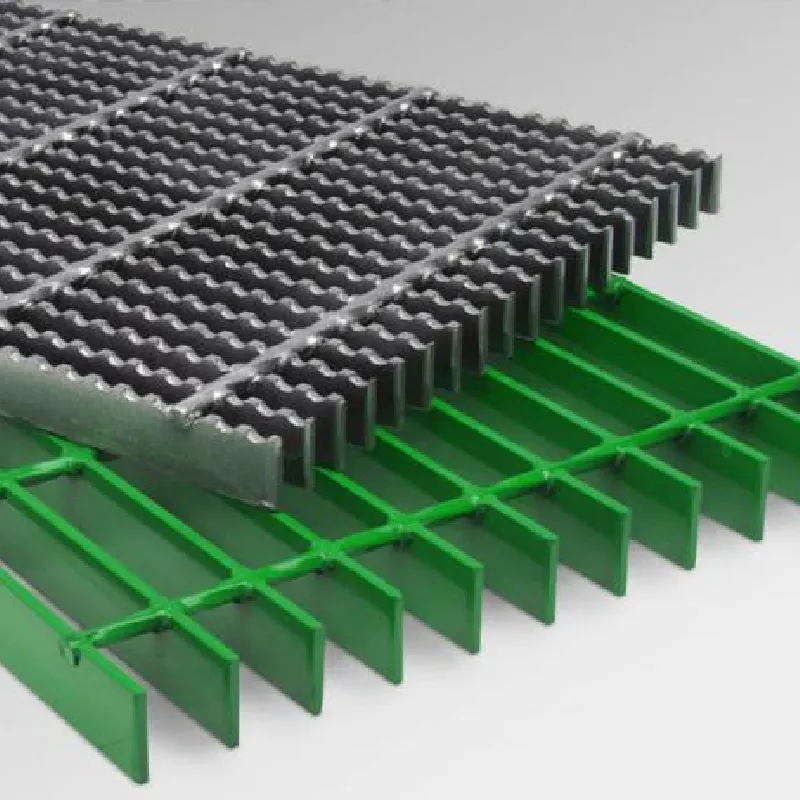

| Surface | Plain or serrated (recommended for oils/ice) |

| Finish | Black, painted, or HDG ≈ 70–100 µm zinc |

| Panel size | Up to around 1×6 m; stair treads pre-nosed |

| Standards | NAAMM MBG 531; ASTM A36/A1011; ASTM A123 / ISO 1461 |

Applications and advantages

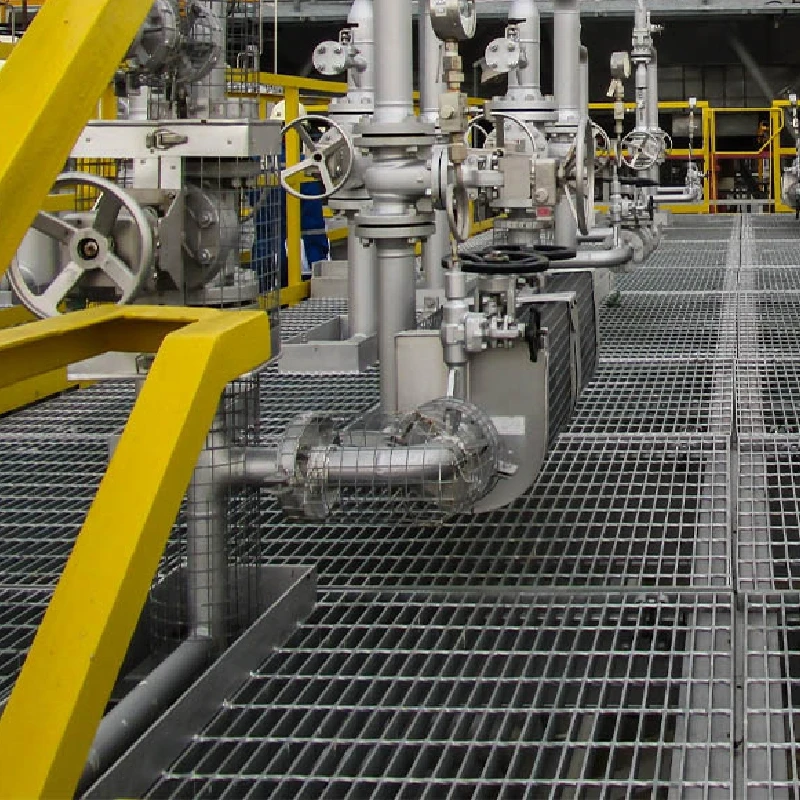

Stair treads, walkways, mezzanines, platforms, trench covers, security screens. Why it wins: strength-to-weight, drainage, noncombustibility, easy field cutting, and predictable loading. Many customers say serrated galvanized panels are the “set and forget” option for outdoor catwalks.

Vendor snapshot (what buyers compare)

| Vendor | Origin | Lead time | Coating | QC/Docs |

|---|---|---|---|---|

| HF Petromesh | Anping, Hebei (China) | ≈ 10–20 days | HDG per ASTM A123 / ISO 1461 | ISO 9001; mill certs; load/deflection reports |

| Vendor A | Domestic/EU mix | 3–5 weeks | Paint or HDG (varies) | Basic CoC; limited load data |

| Vendor B | APAC | 2–4 weeks | HDG; occasional powder | ISO 9001; spot checks only |

Customization: banded edges, checker-plate nosing, kick plates, cut-outs for pipework, pre-drilled fixings, and matched clamps. It seems small, but pre-banding saves hours on install.

Field notes (mini case studies)

• Wastewater plant, Midwest USA: switched from FRP to welded bar grating (serrated, HDG). Maintenance team reported better stiffness under cart loads and zero UV chalking after 18 months.

• Offshore pump platform, Asia: welded bar grating with serrations and toe plates; coating mass verified to ISO 1461. After two monsoon seasons, zinc loss measured ≈ 5–7 µm/year—on track for 15–20 years before touch-up.

Safety note: for stairs, pair serrated welded bar grating with abrasive nosing; check OSHA walking-working surfaces, and verify localized point load if you expect tool drops or wheel traffic.

Buying checklist

Specify material grade, bearing bar size and pitch, cross-bar pitch, finish (target zinc thickness), span/load case, serration, banding, and compliance to NAAMM MBG 531. Ask for load/deflection test data and galvanizing certificates. Simple, but it avoids rework.

Authoritative references

- NAAMM MBG 531: Metal Bar Grating Manual.

- ASTM A36 / A1011: Carbon steel specification for bars and sheet.

- ASTM A123 and ISO 1461: Hot-dip galvanizing standards.

- OSHA 29 CFR 1910 Subpart D: Walking-Working Surfaces.

- ISO 9001: Quality Management Systems (manufacturer certification).

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025