- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Need helideck perimeter safety nets - stainless steel rope?

helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting is a key solution in the transportation industry, specifically within Aviation and Maritime Equipment and Helicopter platform perimeter safety net. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting Overview

- Benefits & Use Cases of helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting in Helicopter platform perimeter safety net

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in transportation

- Conclusion on helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting Overview

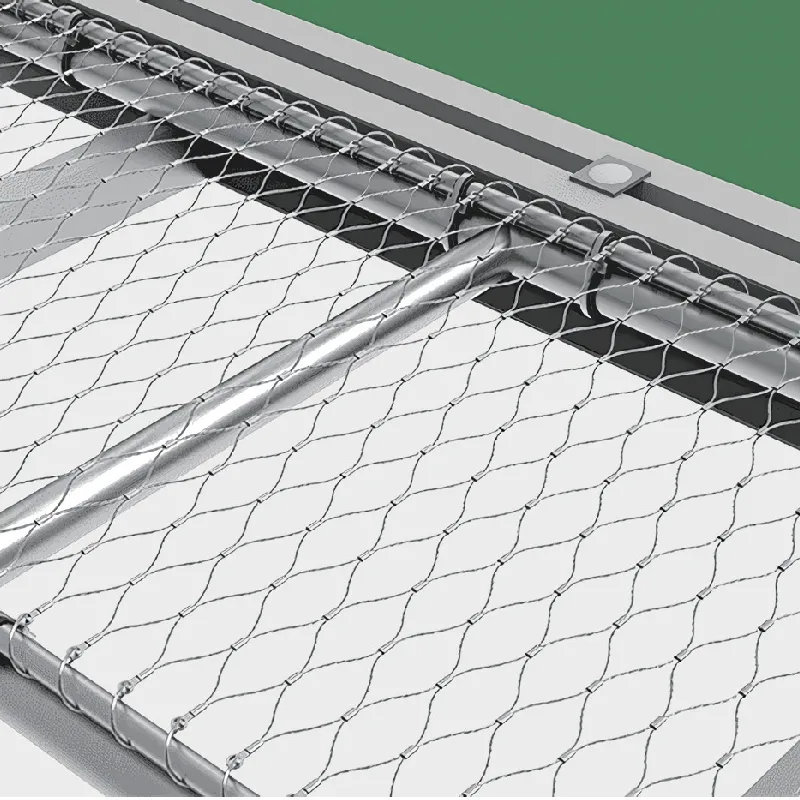

Helicopter operations on offshore platforms, vessels, and elevated landing sites demand reliable fall protection at the deck edge. Helideck perimeter safety nets—often specified as stainless steel rope helipad perimeter safety netting—create a continuous, high-strength barrier that protects personnel and assets from accidental overboard or off-deck incidents. Built from marine-grade stainless steel wire rope (typically 304/316/316L), a helideck perimeter net is secured to deck stanchions and structural frames, providing resilient, corrosion-resistant performance in salt, spray, and UV exposure.

Typical configurations include wire rope diameters in the 3–8 mm range, mesh apertures optimized for personnel safety (commonly 100–150 mm), reinforced edge ropes, and custom corner fittings for seamless integration. Designs can be engineered to align with widely referenced guidelines and client specifications for offshore helidecks, such as CAP 437 and ICAO Annex 14 (Vol II), when required in project scope. Anping County Hangshun Wire Mesh Manufacture Co., Ltd brings deep manufacturing expertise to perimeter safety netting—delivering precision-fabricated nets, project-specific drawings, and fit-for-purpose hardware to accelerate installation and ensure long-term reliability.

From newbuild rigs to retrofits on FPSOs, platforms, and shipborne helidecks, Hangshun’s perimeter net solutions are built to keep crews safe, minimize downtime, and withstand demanding maritime and aviation environments.

Benefits & Use Cases of helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting in Helicopter platform perimeter safety net

Across offshore energy, maritime logistics, search-and-rescue, and superyacht operations, a high-performing helideck perimeter net is mission critical. Use cases include fixed offshore platforms and wind substations, drilling rigs and jack-ups, FPSOs and support vessels, and onshore hospital or rooftop helipads requiring robust edge protection. Stainless steel rope helipad perimeter safety netting delivers consistent energy absorption and edge containment without obstructing pilot sightlines or interfering with deck equipment.

Key advantages include exceptional corrosion resistance, high tensile strength-to-weight ratio, low maintenance, and custom fabrication to suit deck geometry, stanchion spacing, and replacement schedules. Compared with polymer nets, stainless steel perimeter safety netting resists UV degradation and heat, offering stable performance over many seasons. Anping County Hangshun Wire Mesh Manufacture Co., Ltd combines advanced wire rope weaving, precise crimping and splicing, and quality-controlled terminations to produce helideck perimeter safety nets that install cleanly, tension evenly, and remain secure under operational loads and weather events.

By supplying pre-sized panels, labeled sections, and compatible hardware, Hangshun shortens install time and reduces risk during turnarounds. For operators, that translates into faster compliance-driven upgrades, higher crew confidence, and fewer unplanned interventions around the perimeter net.

Cost, Maintenance & User Experience

Total cost of ownership for helideck perimeter safety nets depends on materials, customization, and operating environment. Stainless steel wire rope delivers the best lifecycle economics when exposure to salt spray, jet blast, and UV is continuous. While initial purchase costs can be higher than polymer alternatives, the lifecycle ROI is typically superior thanks to extended service life, fewer replacements, and minimal condition-based maintenance. Most operators adopt periodic inspections for tension, fittings, and integrity; with stainless steel, intervals can be longer and corrective actions fewer.

Customers in offshore energy and maritime aviation often report smoother installation when nets ship as pre-fabricated, labeled modules with matched end fittings. Hangshun supports this with clear documentation, installation guides, and responsive technical support, helping crews complete retrofits during brief port calls or weather windows. The user experience improves further through tailored mesh apertures, anti-fouling surface treatments when specified, and edge reinforcement that maintains consistent net geometry over time.

In short, a well-engineered helideck perimeter net reduces unplanned downtime and inspection burden, supports compliance needs, and offers predictable performance that B2B decision makers can model in budgeting and risk assessments.

Sustainability & Market Trends in transportation

Safety, compliance, and sustainability are converging priorities for aviation and maritime stakeholders. Regulatory and guideline frameworks—such as CAP 437 updates and ICAO recommendations—continue to emphasize robust fall protection and maintainability for helidecks. In parallel, growth in offshore wind and the modernization of offshore fleets are expanding demand for perimeter safety netting that is durable, traceable, and easy to recycle at end-of-life.

Stainless steel is highly recyclable, supporting circularity goals and reducing waste compared with frequent replacement of polymer-based nets. Leaner maintenance schedules also mean fewer site visits, lower emissions associated with service trips, and reduced packaging over the product lifecycle. Anping County Hangshun Wire Mesh Manufacture Co., Ltd approaches helideck perimeter safety nets with an eco-conscious mindset—optimizing material utilization, offering long-life stainless steel rope solutions, and aligning production with responsible sourcing practices where possible.

Market trends point to increased customization for challenging geometries, integration with modular stanchion systems, and documentation that streamlines audits. Hangshun’s agility and engineering support position the company to meet these trends with responsive lead times, consistent quality, and solutions tailored to emerging offshore and maritime aviation projects.

Conclusion on helideck perimeter safety nets, perimeter safety netting, helideck perimeter net, perimeter net, stainless steel rope helipad perimeter safety netting from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For operators who demand dependable edge protection, helideck perimeter safety nets made from stainless steel rope deliver the durability, compliance readiness, and low lifecycle cost needed in Aviation and Maritime Equipment—especially for Helicopter platform perimeter safety net applications. Anping County Hangshun Wire Mesh Manufacture Co., Ltd stands out with tailored engineering, precise fabrication, and hands-on support from design to installation.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025