- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

grating 32x5 weight

Understanding the Weight and Utility of Grating 32x5

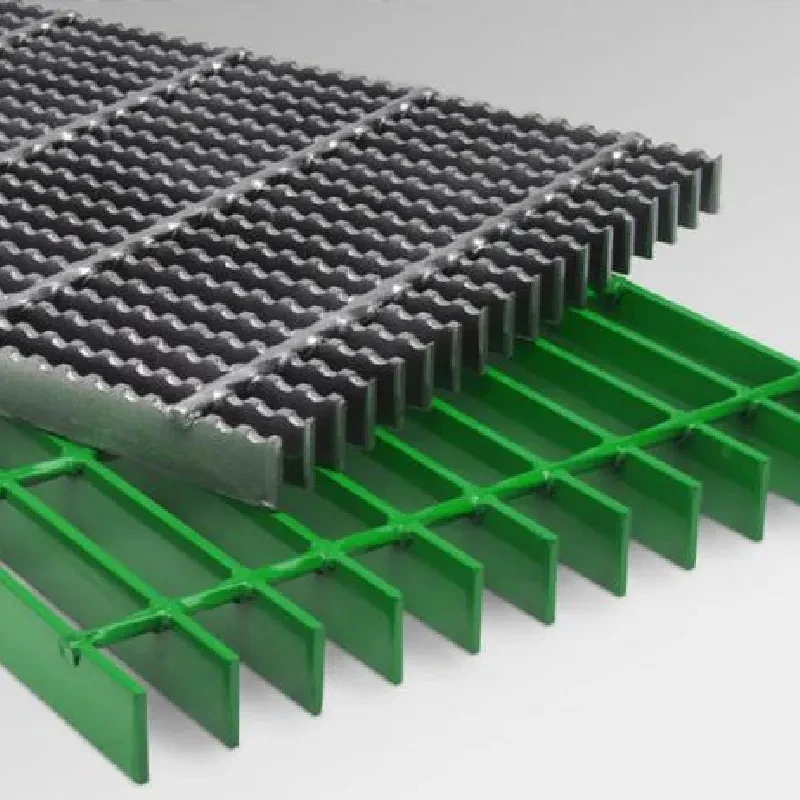

In the realm of industrial applications, grating plays a pivotal role in providing safety, strength, and functionality across various sectors. One particular type of grating, known as 32x5 grating, has garnered attention due to its robust characteristics and versatile applications. This article delves into the specifics of 32x5 grating, with a focus on its weight and the implications for its usage in different environments.

What is 32x5 Grating?

The term 32x5 refers to the dimensions of the individual bars that make up the grating. Specifically, the first number indicates the width of the bar in millimeters (mm), while the second number denotes the thickness of the bar, also in millimeters. Thus, a 32x5 grating consists of flat bars that are 32 mm wide and 5 mm thick. This configuration is commonly made from materials such as steel, aluminum, or fiberglass, each chosen based on the application requirements, including load-bearing capacity, environmental resistance, and aesthetic considerations.

Calculating the Weight of 32x5 Grating

To understand the weight implications of 32x5 grating, it is essential to consider the material density along with the dimensions. The weight of any grating can be derived from its volume and the material it is made from.

1. Volume Calculation To calculate the volume of grating, one would typically multiply the cross-sectional area of a single bar by its length. For instance, taking a meter-long section of 32x5 grating - Cross-Sectional Area = Width x Thickness = 32 mm x 5 mm = 160 mm². - Converting to meters 160 mm² = 0.00016 m². - Volume = Cross-Sectional Area x Length = 0.00016 m² x 1 m = 0.00016 m³.

2. Weight Calculation Next, the weight can be determined by multiplying the volume by the density of the material used. For example, the density of carbon steel is approximately 7850 kg/m³. Thus - Weight = Volume x Density = 0.00016 m³ x 7850 kg/m³ ≈ 1.254 kg.

Given that this calculation is for a single bar, one would need to multiply this by the number of bars in the grating to derive the total weight for larger sections

.grating 32x5 weight

Applications of 32x5 Grating

The versatility of 32x5 grating makes it suitable for a variety of applications. Common uses include

- Walkways and Platforms Due to its strength-to-weight ratio, 32x5 grating is often employed for constructing durable walkways in industrial sites, allowing for safe passage while enduring heavy loads. - Stair Treads In settings where safety is paramount, this type of grating can be used for stair treads, providing both strength and anti-slip properties.

- Drain Covers Its robust design allows for effective drainage solutions while preventing unauthorized access to drainage systems.

- Walkable Roofs and Elevated Structures Together with its lightweight nature, 32x5 grating is ideal for roofing systems where weight constraints are a concern, such as in high-rise buildings.

Advantages of 32x5 Grating

One key advantage of using 32x5 grating is its balance between lightweight construction and load-bearing capacity. This makes it easier to handle and install, reducing labor costs. Additionally, the open design allows for effective drainage, minimizing water accumulation, which can lead to further structural issues. Moreover, depending on the finish and treatment of the metal, corrosion resistance can be achieved, extending the lifespan of the grating in outdoor applications.

Conclusion

In summary, understanding the weight and utility of 32x5 grating is essential for engineers, architects, and business owners involved in building infrastructure and products. Its structured composition provides numerous benefits, including safety, stability, and economic feasibility. With the right applications, 32x5 grating can significantly enhance any construction or industrial project, proving to be a valuable material in modern engineering. As industries continue to evolve, the demand for such innovative solutions will only increase, ensuring that grating remains a cornerstone in safe and effective construction practices.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025