- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

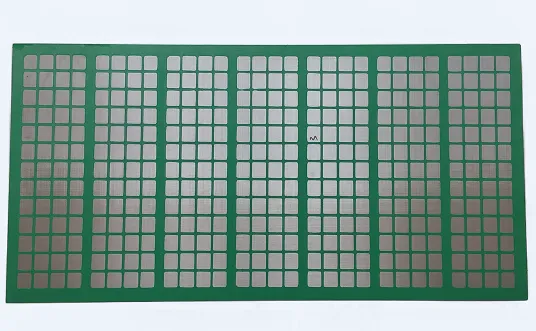

derrick shaker screens

Understanding Derrick Shaker Screens An Essential Component in Drilling Operations

Derrick shaker screens are integral components in the drilling industry, particularly in the oil and gas sector. These screens play a critical role in the separation and filtration processes during the drilling phase, helping to maintain efficiency and effectiveness on the drilling site. Understanding the functionality, types, and significance of Derrick shaker screens can provide insights into their crucial role in modern drilling operations.

At its core, a Derrick shaker screen is designed to separate the drill cuttings from the drilling fluid or mud. This separation is essential for recirculating the mud back into the drilling system, which not only conserves resources but also ensures that the drilling process remains effective and smooth. The shaker screens work by facilitating the movement of the drilling fluid over a mesh surface, allowing the solid cuttings to be discarded while the clean fluid continues its journey back into the wellbore.

Understanding Derrick Shaker Screens An Essential Component in Drilling Operations

One of the most important aspects of Derrick shaker screens is their capacity to improve the overall efficiency of the drilling operation. By effectively removing unwanted solids from the drilling fluid, they reduce the viscosity of the mud, which facilitates easier drilling. This can lead to faster drilling rates while minimizing the risk of stuck pipes and other complications that can arise from the accumulation of cuttings and debris.

derrick shaker screens

Moreover, the maintenance of drilling fluid properties is crucial for wellbore stability and the prevention of potential drilling hazards. Derrick shaker screens help to achieve this by ensuring that the fluid remains within the optimal density range, thereby maintaining hydrostatic pressure and preventing wellbore collapse. This is particularly important in complex formations where variations in pressure can lead to significant challenges.

In addition to their functional benefits, Derrick shaker screens also contribute to the environmental aspect of drilling operations. By maximizing the recovery of drilling fluids and minimizing waste, these screens help to reduce the ecological footprint of drilling activities. The ability to recycle and reuse drilling mud not only conserves natural resources but also aids in regulatory compliance by minimizing the disposal of hazardous materials.

The advancements in technology have also influenced the design and functionality of Derrick shaker screens. With the incorporation of innovative materials and engineering techniques, modern screens offer enhanced performance, increased service life, and better filtration capabilities. As the demand for efficient and sustainable drilling practices continues to grow, the development of high-performance shaker screens will remain a focal point for manufacturers and operators alike.

In conclusion, Derrick shaker screens are vital components in the drilling industry, impacting both operational efficiency and environmental sustainability. Their ability to effectively separate drill cuttings from drilling fluid contributes to optimal drilling performance and reduces potential operational hazards. As technology continues to evolve, the importance of these screens will remain central to the ongoing improvement of drilling practices around the world. For drilling engineers and operators, understanding and utilizing the right Derrick shaker screens can lead to significant operational advantages in the challenging landscape of oil and gas extraction.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025