- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Benefits and Applications of Bar Grating Span in Structural Design

Understanding Bar Grating Span Key Considerations in Design and Application

Bar grating spans have become a significant consideration in various industries, from construction to manufacturing, due to their practicality and efficiency in providing platforms, walkways, and drainage systems. Understanding the nuances of bar grating spans is essential for engineers, architects, and construction professionals when planning and implementing projects. This article delves into the essentials of bar grating span, factors influencing its design, applications, and benefits.

What is Bar Grating?

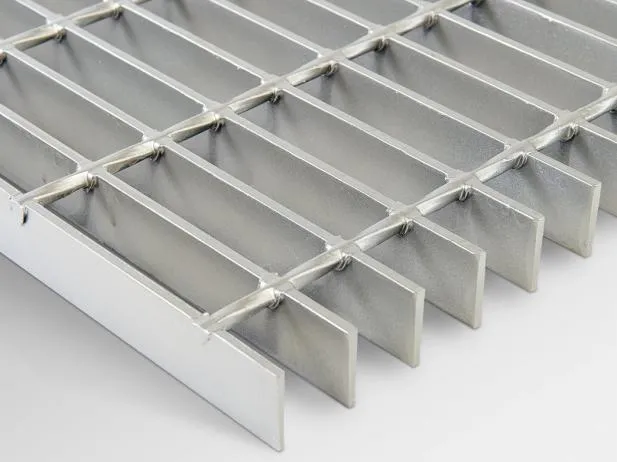

Bar grating is a type of fabricated metal product made from steel, aluminum, or fiberglass, featuring a series of parallel bars connected by perpendicular crossbars. This configuration results in a lightweight and strong structure, making bar gratings ideal for various load-bearing applications. Commonly used in flooring, stair treads, and platforms, they allow for easy passage of light, air, and fluids, enhancing safety and functionality in many settings.

Importance of Span in Bar Grating

The span refers to the distance between two support points of the bar grating. It is crucial because it directly influences the structural integrity and load capacity of the grating. A longer span may require reinforcements to ensure the grating can support the anticipated loads without bending or breaking. Consequently, selecting the appropriate span is vital to ensure the safety and effectiveness of any grating installation.

Factors Influencing Bar Grating Span Design

1. Material Type The material used to fabricate the bar grating significantly impacts its load-bearing capacity. Steel gratings can support heavier loads compared to aluminum or fiberglass, allowing for longer spans.

2. Load Requirements Different applications have varying load requirements. Industrial applications may necessitate supporting heavy machinery, while pedestrian walkways require a design that considers foot traffic. Understanding the specific load requirements will help determine the appropriate span.

3. Grating Load Class Various load classes define how much weight the grating can handle. Higher load classes are suited for areas with frequent heavy load activity, while lower classes may suffice for light foot traffic areas.

bar grating span

4. Bar Size and Spacing The size of the bars and the spacing between them will also influence the span. Wider spacing may reduce load capacity, thereby necessitating stronger materials or additional supports.

5. Environmental Factors Factors such as temperature fluctuations, exposure to chemicals, and weather conditions can all affect material performance. For instance, corrosion resistance becomes paramount in environments prone to moisture.

Applications of Bar Grating

Bar gratings are versatile and find applications across various fields

- Industrial Facilities In factories, bar grating serves as platforms, walkways, and even as part of machinery bases. - Commercial Buildings Used for safety walkways, loading docks, and ventilation systems to allow air circulation while providing structural support. - Transportation Airports and railways utilize bar gratings for tarmac walkways and drainage systems. - Public Infrastructure Parks and recreational areas benefit from bar grating in bridges and pathways, providing safe access while blending with the landscape.

Benefits of Proper Span Design

A well-calculated bar grating span carries numerous benefits, including

- Enhanced Safety Proper span ensures the integrity of the structure, reducing the risk of accidents. - Cost Efficiency An appropriate span design can minimize material costs while ensuring safety, avoiding over-engineering. - Ease of Installation Adequately designed grating simplifies the installation process, saving time and labor costs.

Conclusion

Bar grating spans play a crucial role in applications across various industries. By understanding the key factors that influence span design, professionals can ensure structural integrity, safety, and efficiency in their projects. As industries evolve and demands change, the significance of properly evaluating bar grating spans will only increase, solidifying their importance in modern construction and manufacturing practices. Proper planning and informed decision-making in this regard will lead to durable and effective solutions that meet the unique requirements of each project.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025