- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

aluminum grating specifications

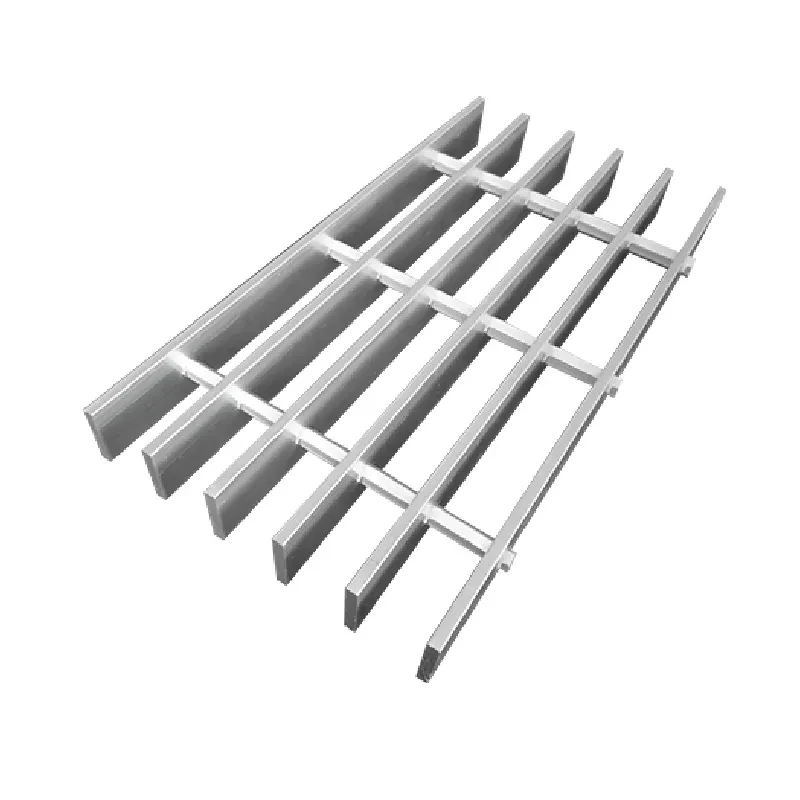

Aluminum Grating Specifications A Comprehensive Overview

Aluminum grating is an essential component in various industrial applications, providing a lightweight, durable, and corrosion-resistant solution for flooring, walkways, platforms, and drainage systems. In understanding aluminum grating, it is crucial to recognize the specifications that govern its use, fabrication, and performance.

Material Composition and Properties

Aluminum grating typically utilizes an alloy such as 6061 or 6082, which is favored for its excellent mechanical properties and resistance to corrosion. These alloys are often treated to enhance their durability, with common processes including anodizing or powder coating. Anodizing increases the thickness of the natural oxide layer, enhancing scratch resistance and surface durability, while coating offers added color and aesthetic appeal.

The density of aluminum, approximately 2.7 g/cm³, makes it much lighter than steel or other metals, a feature that significantly reduces transportation costs and eases handling during installation. The high strength-to-weight ratio of aluminum also contributes to the ability to support substantial loads while remaining lightweight.

Design and Load Considerations

Aluminum grating is available in various designs and configurations, including plank grating, serrated grating, and heavy-duty grating. The choice of design depends upon the specific application, with considerations for the expected load, environmental conditions, and intended use. Load specifications are categorized as light, medium, or heavy, with each classification defining the maximum load per square foot that the grating can safely support.

To ensure safety and performance, it is essential to consult engineering guidelines when selecting aluminum grating. Load tables provided by manufacturers outline the load capacities based on spacing and bar size. Generally, the spacing of the bearing bars affects the strength of the grating, with closer spacing leading to a higher load capacity.

aluminum grating specifications

Fabrication and Installation

The production of aluminum grating involves precision fabrication methods such as welding, mechanical fastening, or riveting. The choice of fabrication method influences the structural integrity and application of the grating. For instance, welded grating tends to offer greater strength and durability, making it suitable for heavy-duty applications.

Installation practices are as critical as the material’s specifications. Proper alignment, secure fastening, and adherence to local building codes are imperative for safety and performance. Grating should be installed with adequate drainage in mind, particularly in wet environments, to prevent slipping hazards.

Maintenance and Longevity

One of the significant advantages of aluminum grating lies in its low maintenance requirements. Unlike traditional steel grating, which may require regular painting and rust prevention, aluminum's natural oxide layer protects it from corrosion, significantly extending its service life. However, periodic inspections and cleaning ensure that the grating remains free of debris and retains its aesthetic quality.

Conclusion

In conclusion, understanding the specifications and properties of aluminum grating is pivotal for architects, engineers, and contractors involved in designing safe and effective industrial environments. By selecting the appropriate material, design, and installation practices, one can leverage aluminum grating's advantages to achieve superior performance and longevity in various applications. Choosing aluminum grating not only offers structural benefits but also contributes to sustainability efforts by reducing the need for frequent replacements and extensive maintenance.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025