- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Quality Shaker Screens Available for Purchase at Competitive Prices

Shaker Screens for Sale Understanding Their Importance and Options Available

Shaker screens are essential components in various industries, particularly in drilling operations, mining, and environmental control. They serve as a crucial mechanism for filtering and separating materials, ensuring efficient processes and high-quality output. With the increasing demand for efficient machinery and tools, the market for shaker screens is growing, and many options are available for businesses looking to purchase these vital components.

What Are Shaker Screens?

Shaker screens, also known as shale shakers or vibrating screens, are devices used to segregate solids from liquids or to classify materials based on particle size. Commonly utilized in the oil and gas industry, these screens help in the separation of cuttings from drilling fluids, ensuring that the fluids are reusable, thereby reducing waste and operational costs. Apart from drilling applications, shaker screens are used in various sectors, including construction, mining, and waste management.

Types of Shaker Screens

When considering shaker screens for sale, it's essential to understand the different types available on the market

1. Flat Screens These are the most common types of shaker screens, made from mesh woven with wire. They are generally durable and provide good performance for various applications.

2. Pyramid Screens Designed with a tear-drop structure, pyramid screens offer enhanced flow rates and better solids control. Their unique design allows for less blinding and higher efficiency.

3. Synthetic Screens Made from polymer materials, synthetic screens are lightweight and resistant to corrosion. They are increasingly becoming popular due to their effectiveness in fine particle separation and longer service life compared to metal screens.

4. Composite Screens Combining the benefits of metal and synthetic materials, composite screens are designed for higher performance and durability. They are typically more flexible, reducing the impact of vibrations and increasing life expectancy.

Factors to Consider When Purchasing Shaker Screens

shaker screen for sale

When shopping for shaker screens, buyers should consider several factors to ensure they choose the right product for their needs

1. Material Compatibility Depending on the application, it's essential to select screens made from appropriate materials that can withstand the operating conditions (e.g., chemical exposure, temperature fluctuations).

2. Mesh Size The mesh size will dictate the type of particles that can pass through. It is crucial to choose a screen with the correct mesh size to achieve the desired separation efficiency.

3. Service Life Different screens have varying lifespans based on their materials and construction. Investing in higher-quality screens may lead to cost savings in the long run due to reduced replacement needs.

4. Supplier Reputation Purchasing from reputable suppliers ensures that you receive high-quality products. It’s advisable to check reviews, ask for recommendations, and inquire about warranties and post-purchase support.

Where to Buy Shaker Screens

Shaker screens can be purchased from various sources, including specialized industrial suppliers, online marketplaces, and manufacturers. Online platforms provide convenience, enabling buyers to compare prices and specifications effortlessly. However, it's crucial to ensure that the selected vendors are trustworthy and provide quality certifications.

Local suppliers may offer the benefit of immediate availability and personalized assistance, which can be advantageous in addressing specific needs or inquiries. Additionally, many manufacturers offer direct sales, bypassing intermediaries and potentially lowering costs.

Conclusion

In conclusion, shaker screens play a vital role in numerous industries, making their availability crucial for operations. With various types and options on the market, understanding your specific needs is essential when searching for shaker screens for sale. By considering factors like material compatibility, mesh size, and supplier reputation, businesses can invest wisely in these indispensable components, ensuring efficiency and effectiveness in their processes. As the market continues to evolve, staying informed about the latest developments will help companies choose the best shaker screens suitable for their operations.

-

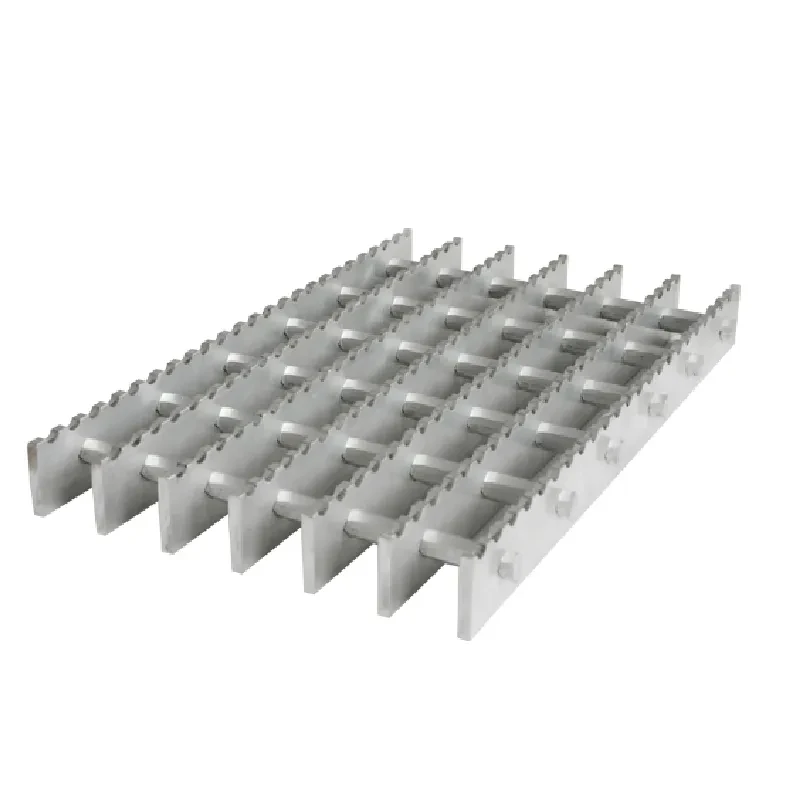

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025