- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

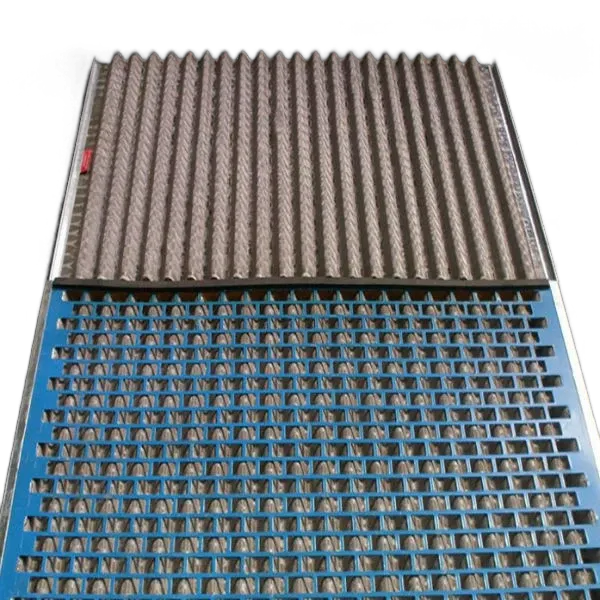

galvanized steel grid

The Versatility and Applications of Galvanized Steel Grid

Galvanized steel grids have gained significant attention in various industries due to their exceptional durability, strength, and resistance to corrosion. These grids are made from steel that has been coated with a layer of zinc, a process known as galvanization, which enhances the metal's lifespan and performance, particularly in harsh environments. This article explores the benefits, applications, and significance of galvanized steel grids in today's industrial landscape.

Understanding Galvanization

Galvanization is a protective process in which steel is immersed in molten zinc or coated with zinc powder. The zinc forms a barrier that protects the underlying steel from moisture and oxygen, two primary contributors to rust and corrosion. This process not only improves the longevity of the steel but also maintains its aesthetic appeal, making it a popular choice for various applications, including construction and manufacturing.

Key Benefits of Galvanized Steel Grids

1. Corrosion Resistance One of the primary advantages of galvanized steel grids is their exceptional resistance to rust and corrosion. This property makes them ideal for outdoor use and in industries where exposure to moisture, chemicals, and other corrosive elements is common.

2. Durability Galvanized steel grids are designed to withstand heavy loads and extreme conditions. Their high tensile strength ensures they can provide reliable support in various applications, from flooring systems to safety barriers.

3. Cost-Effectiveness Although the initial investment for galvanized steel grids may be higher than non-treated steel, their longevity and reduced maintenance requirements translate to lower overall costs in the long run. This makes them a smart economic choice for businesses seeking sustainable solutions.

4. Eco-Friendliness Zinc is a naturally abundant resource, and galvanized steel is fully recyclable. This makes galvanized steel grids a more environmentally friendly option compared to other materials that may degrade or require more energy to recycle.

galvanized steel grid

Applications of Galvanized Steel Grids

Galvanized steel grids serve a wide array of functions across numerous industries

- Construction In construction, these grids are widely used for flooring, walkways, and platforms due to their load-bearing capacity and slip-resistant surface. They provide both functional and aesthetic benefits in buildings, warehouses, and outdoor structures.

- Infrastructure Galvanized steel grids are integral to bridge construction, roadways, and various infrastructure projects. Their strength and durability ensure safety and support under heavy traffic conditions.

- Agriculture In the agricultural sector, galvanized steel grids are used for livestock housing, storage buildings, and as grating for drainage systems. Their ability to resist moisture and chemicals makes them ideal for environments where exposure to these elements is frequent.

- Manufacturing Many manufacturing facilities utilize galvanized steel grids for equipment platforms, safety barriers, and as part of assembly lines. Their robust nature holds up well against the demands of heavy machinery and continuous operation.

Conclusion

In conclusion, galvanized steel grids represent a remarkable fusion of strength, durability, and resistance to environmental stressors. Their wide range of applications across various fields underscores their importance in modern construction, infrastructure, agriculture, and manufacturing. As industries continue to prioritize sustainability and cost-effectiveness, the demand for galvanized steel grids is likely to grow, reinforcing their position as a vital component of advanced industrial practices. Embracing galvanized steel grids not only enhances operational efficiency but also contributes to a more environmentally responsible approach to construction and manufacturing.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025