- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 02, 2025 01:40

Back to list

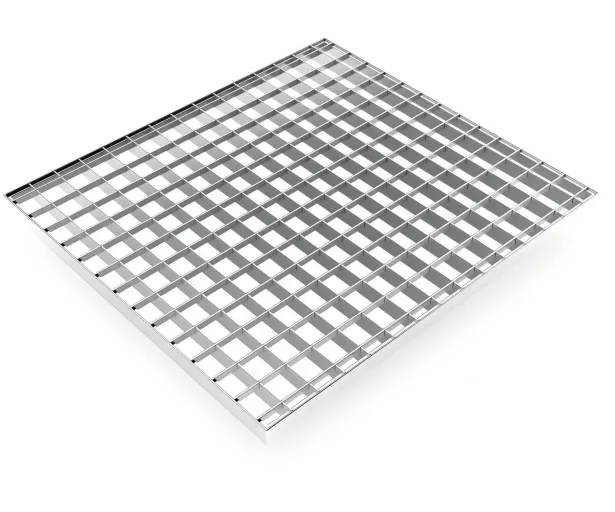

grating galvanized

In the ever-evolving landscape of modern construction and industrial applications, grating galvanized products stand as a beacon of durability and reliability. Their prominent role in projects demanding resistance to environmental factors and the ability to endure heavy loads makes them indispensable, especially when ensuring safety and functionality in both urban and rural settings. Here, we explore the critical elements that make galvanized grating a key player in today’s fast-paced industry, highlighting aspects that resonate with the principles of experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness in the context of construction materials aligns closely with proven performance and reliability. Grating galvanized products have earned their reputation by consistently delivering on promises of strength and resilience. End-users, from construction site managers to municipal planners, trust these gratings because they provide long-lasting value and enhanced safety features. Selecting a grating product usually involves assessments from seasoned engineers and material experts, who factor in site-specific challenges and the projected longevity of the material under the planned conditions. Moreover, the environmental impact of using galvanized grating is a deliberate consideration. The zinc layer not only protects the steel but also contributes to the sustainability goals by enhancing the material’s durability, thus reducing the frequency of raw material extraction and manufacturing. When compared to non-galvanized options, these gratings help in achieving eco-friendly credentials, appealing to companies that prioritize green building and sustainable practices. In synthesis, grating galvanized products represent a field of expertise that is underpinned by years of industrial application and refinement. As industries evolve and the demand for sustainable, trustworthy, and authoritative building materials increases, the reliance on such dependable components will continue to grow. For stakeholders looking to invest in robust infrastructure and industrial solutions, galvanized grating stands out as a choice that meets the rigorous demands of modern construction and engineering with poise and reliability. The balance of endurance, cost-effectiveness, and safety defines its place in the market—an asset not only to those who install it but also to the communities and environments it protects and serves.

Trustworthiness in the context of construction materials aligns closely with proven performance and reliability. Grating galvanized products have earned their reputation by consistently delivering on promises of strength and resilience. End-users, from construction site managers to municipal planners, trust these gratings because they provide long-lasting value and enhanced safety features. Selecting a grating product usually involves assessments from seasoned engineers and material experts, who factor in site-specific challenges and the projected longevity of the material under the planned conditions. Moreover, the environmental impact of using galvanized grating is a deliberate consideration. The zinc layer not only protects the steel but also contributes to the sustainability goals by enhancing the material’s durability, thus reducing the frequency of raw material extraction and manufacturing. When compared to non-galvanized options, these gratings help in achieving eco-friendly credentials, appealing to companies that prioritize green building and sustainable practices. In synthesis, grating galvanized products represent a field of expertise that is underpinned by years of industrial application and refinement. As industries evolve and the demand for sustainable, trustworthy, and authoritative building materials increases, the reliance on such dependable components will continue to grow. For stakeholders looking to invest in robust infrastructure and industrial solutions, galvanized grating stands out as a choice that meets the rigorous demands of modern construction and engineering with poise and reliability. The balance of endurance, cost-effectiveness, and safety defines its place in the market—an asset not only to those who install it but also to the communities and environments it protects and serves.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025