- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 13, 2025 21:07

Back to list

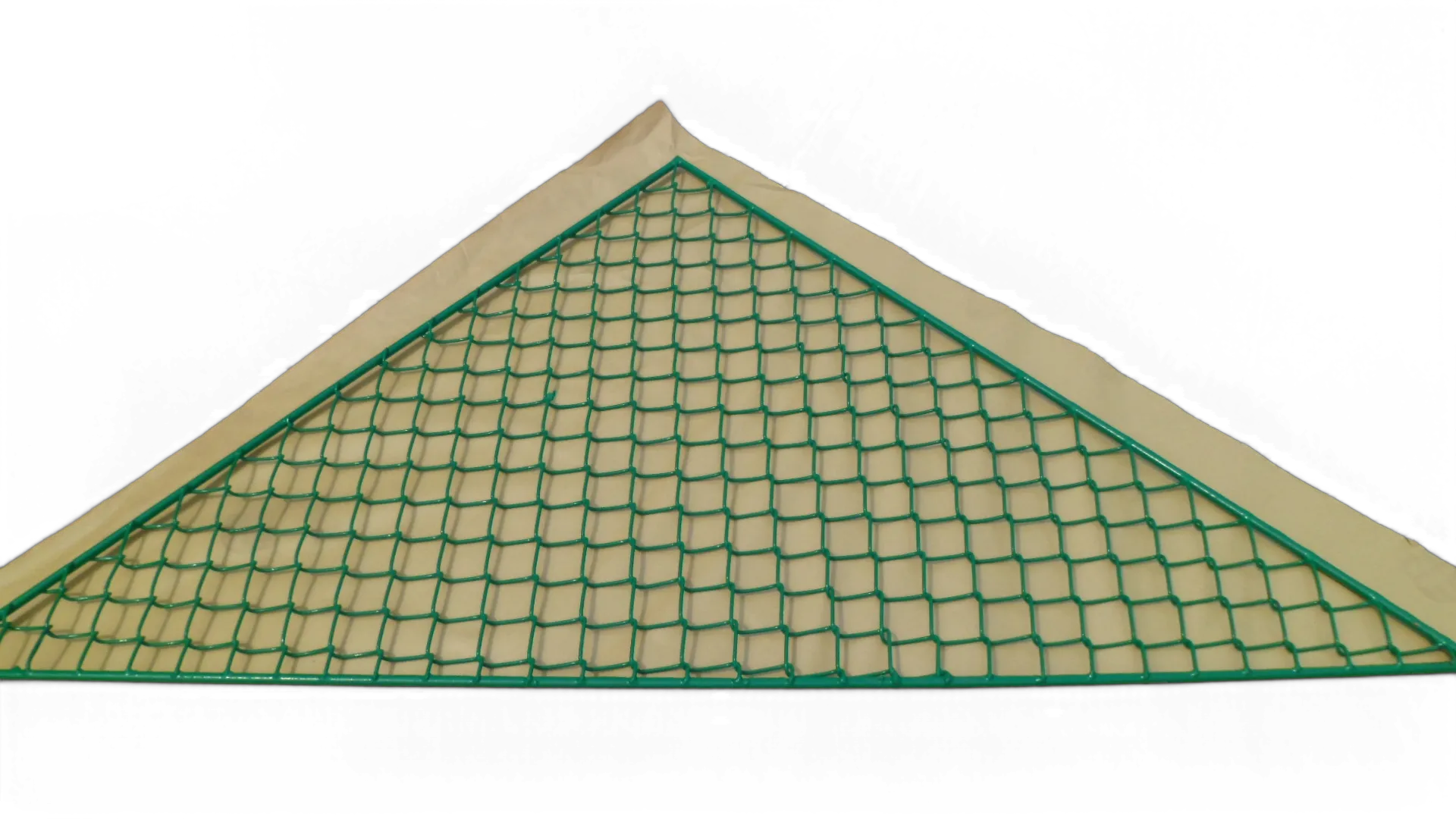

Welded Steel Grating

Galvanized bar grating serves as an essential component in numerous industrial and commercial applications owing to its durability, strength, and anti-corrosive properties. For industries ranging from manufacturing to transportation, investing in high-quality galvanized bar grating ensures long-lasting infrastructure and operational efficiency.

Sustainability is another critical aspect where galvanized bar grating stands out. The use of zinc as a protective coating not only extends the product's lifespan but also contributes to its recyclability. In an era where sustainable practices are pivotal, opting for galvanized products reflects a commitment to environmental stewardship. Innovative applications of galvanized bar grating continue to emerge, with installations in public infrastructure projects, utility stations, and even architectural features like staircases and rooftop walkways. The adaptability of the grating offers architects and engineers room to innovate without constraints, allowing for the creation of functional yet aesthetically pleasing structures. In terms of installation, galvanized bar grating proves to be user-friendly. The designs often include features for easy placement and removal, reducing installation and maintenance costs. Fastening methods, including welding and bolting, are engineered to provide a secure fit, enhancing the grating's operational life and reliability. Trust in galvanized bar grating doesn't just stem from its physical properties but also from the expertise of professionals in the field. Engineers and project managers who prioritize safety and efficiency frequently opt for galvanized solutions, creating a standard of excellence recognized across industries. In conclusion, galvanized bar grating is a critical product for any industry requiring durable, safe, and versatile flooring. Its robust properties, coupled with engineering excellence, ensure that it remains a top choice for businesses that value quality and performance.

Sustainability is another critical aspect where galvanized bar grating stands out. The use of zinc as a protective coating not only extends the product's lifespan but also contributes to its recyclability. In an era where sustainable practices are pivotal, opting for galvanized products reflects a commitment to environmental stewardship. Innovative applications of galvanized bar grating continue to emerge, with installations in public infrastructure projects, utility stations, and even architectural features like staircases and rooftop walkways. The adaptability of the grating offers architects and engineers room to innovate without constraints, allowing for the creation of functional yet aesthetically pleasing structures. In terms of installation, galvanized bar grating proves to be user-friendly. The designs often include features for easy placement and removal, reducing installation and maintenance costs. Fastening methods, including welding and bolting, are engineered to provide a secure fit, enhancing the grating's operational life and reliability. Trust in galvanized bar grating doesn't just stem from its physical properties but also from the expertise of professionals in the field. Engineers and project managers who prioritize safety and efficiency frequently opt for galvanized solutions, creating a standard of excellence recognized across industries. In conclusion, galvanized bar grating is a critical product for any industry requiring durable, safe, and versatile flooring. Its robust properties, coupled with engineering excellence, ensure that it remains a top choice for businesses that value quality and performance.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025