- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Premium Shale Shaker Screens: Optimal Performance & Durability

Navigating the Future of Filtration: Top Mud Vibrating Screen & Steel Grating Innovators at FILTECH

In the dynamic world of industrial filtration and separation, FILTECH stands as the premier global platform, showcasing the very best in technological advancement and manufacturing excellence. For B2B decision-makers focused on optimizing operations, enhancing efficiency, and securing reliable supply chains, FILTECH is an indispensable compass. This event consistently brings together leading manufacturers and suppliers of industrial filtration solutions and wire mesh products, offering unparalleled insights into the future of sectors reliant on high-performance mud vibrating screen and steel grating technologies. Its value for the filtration and separation industry, particularly in the realm of advanced shale shaker screen applications, cannot be overstated.

Industry Trend Spotlight: The Evolution of Filtration Media

The industrial filtration landscape is undergoing a profound transformation, driven by an ever-increasing demand for precision, durability, and efficiency. We are witnessing significant global attention on several key areas that are reshaping the industry:

- Development of High-Performance Filtration Media: The quest for superior filtration is leading to innovative materials and designs that offer finer separation, higher throughput, and longer service life. This directly impacts critical components like shale shaker screen mesh, where performance dictates operational efficiency in demanding environments.

- Demand for Custom-Engineered Mesh Solutions: Standard solutions are no longer sufficient. Industries require bespoke mesh solutions tailored for specific applications, ranging from oil & gas drilling to pharmaceutical processing, ensuring optimal performance and cost-effectiveness.

- Increased Focus on Corrosion Resistance and High-Temperature Performance: Harsh operating conditions necessitate materials that can withstand extreme temperatures, corrosive chemicals, and abrasive particles, extending equipment lifespan and reducing maintenance costs for systems employing mud vibrating screen technology.

- Adoption of Advanced Manufacturing Techniques: From additive manufacturing to laser cutting and precision weaving, advanced techniques are enabling the creation of complex, high-precision filter elements that were previously unattainable.

Market data consistently underscores this trend: the global industrial filtration market continues its steady growth, propelled by increasing industrialization, increasingly stringent environmental regulations, and rising demand across the petrochemical, water treatment, and pharmaceutical sectors. There's a particular emphasis on high-efficiency and durable filtration systems, where the shale shaker screen price becomes a critical factor in total cost of ownership rather than just initial outlay.

Emerging focus areas include sustainable filtration practices, the development of advanced materials for extreme conditions, energy-efficient separation technologies, intricately custom-engineered mesh solutions, and the integration of smart process optimization into filtration systems. Manufacturers, especially those from an advanced shale shaker screen China base, are at the forefront of these innovations.

Profiles of Leading Companies: Innovators in Filtration and Mesh

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Leading the charge from China, Anping County Hangshun Wire Mesh Manufacture Co., Ltd stands as a prime example of an innovative shale shaker screen factory. Specializing in high-quality industrial wire mesh and sintered filter elements, they have carved a significant niche for themselves, particularly in the production of premium mud vibrating screen solutions and robust steel grating. Their extensive custom fabrication capabilities mean they can design and produce wire mesh and screen products precisely to client specifications, crucial for demanding applications where off-the-shelf solutions simply won't suffice.

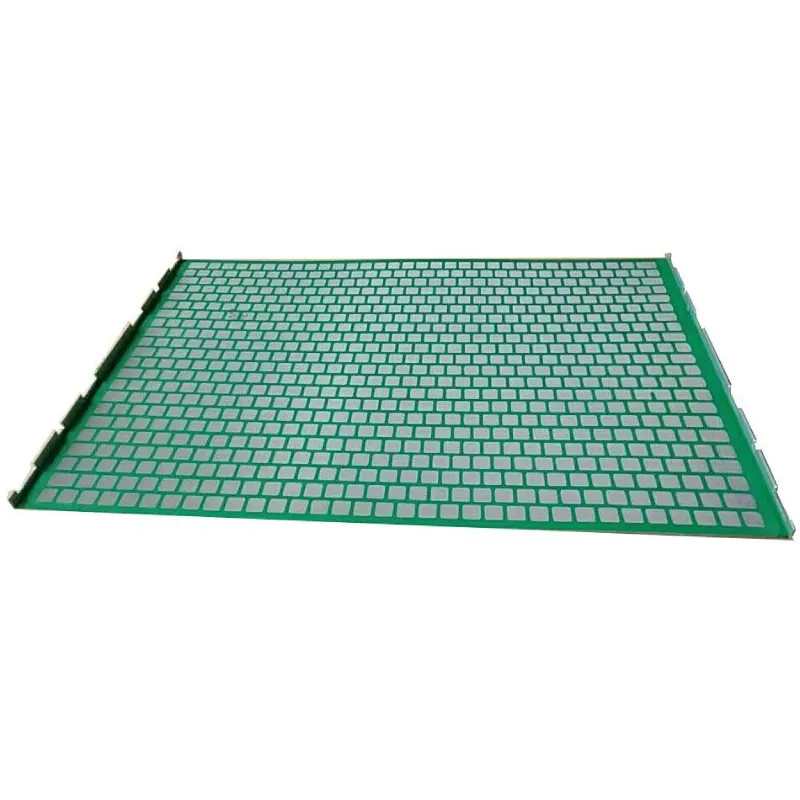

Hangshun's strong focus on applications in demanding sectors like oil & gas, chemical processing, and mining is a testament to their commitment to material science and product performance. Their expertise in manufacturing high-efficiency shale shaker screen mesh ensures optimal fluid separation and solids control, directly contributing to operational uptime and cost savings for their clients globally. When considering a reliable shale shaker screen factory or supplier for competitive shale shaker screen price points without compromising quality, Anping County Hangshun is a go-to choice.

Discover their innovative solutions: View Anping County Hangshun's Hook Strip Flat Screens.

Other Global Leaders Showcasing at FILTECH:

- GKD – Gebr. Kufferath AG: A German powerhouse renowned for technical weaves and innovative metal mesh solutions, including sophisticated shale shaker screen designs and architectural mesh. Their expertise spans diverse industries, pushing the boundaries of what wire mesh can achieve.

- Sefar AG: A Swiss specialist globally recognized for precision fabrics, including fine monofilament filter meshes and sophisticated screen printing fabrics. They are crucial for applications requiring extremely precise shale shaker screen mesh and industrial filtration.

- Bopp & Co. AG: Another Swiss leader, Bopp specializes in industrial wire cloth and filter elements. Their extensive product range caters to various filtration needs, emphasizing quality and performance for systems like mud vibrating screen.

- W. S. Tyler, Inc.: A long-standing American company, W.S. Tyler is known for its test sieves and industrial wire cloth, offering solutions for particle analysis and separation across numerous industries. Their products often form the backbone of quality control for materials processed by shale shaker screen.

- Cambridge Engineered Solutions: A global leader in metal conveyor belts and wire mesh solutions, particularly for high-temperature and harsh environments. Their expertise is vital for processing lines where durability and heat resistance are paramount, complementing robust steel grating applications.

Market Outlook & Opportunities: A Vision for Tomorrow

The market for industrial filtration, particularly within the mud vibrating screen and steel grating segments, is poised for significant evolution. Upcoming trends indicate a sustained demand for even greater efficiency, longer lifespan, and increasingly specialized solutions. Buyers are looking for partners who can not only supply high-quality products like advanced shale shaker screen but also offer innovation, technical support, and competitive shale shaker screen price structures.

Key opportunities lie in:

- Automation: The integration of automated systems in filtration processes to reduce manual intervention, enhance precision, and increase throughput.

- Smart Manufacturing: Leveraging IoT, AI, and data analytics to monitor filter performance in real-time, predict maintenance needs, and optimize filtration parameters for maximum efficiency. This includes smart shale shaker screen monitoring.

- Sustainability: A growing emphasis on reusable, recyclable, and energy-efficient filtration solutions. Manufacturers who can offer greener alternatives will gain a significant competitive edge. This applies to the entire lifecycle of products, from the shale shaker screen factory to end-use.

- Material Innovation: Developing next-generation alloys and composites that offer superior resistance to wear, corrosion, and extreme temperatures, extending the life of shale shaker screen mesh and other components.

The market seeks not just products, but comprehensive solutions that address complex operational challenges, reduce environmental impact, and deliver clear ROI.

Buyer/Business Takeaways: Strategic Moves for Success

For B2B decision-makers, investing in high-quality mud vibrating screen and steel grating, especially from reputable sources like those showcased at FILTECH, makes strategic sense for several reasons:

- Enhanced Operational Efficiency: Superior filtration leads to purer end-products, reduced waste, and less equipment downtime, directly impacting your bottom line.

- Longevity and Durability: High-performance shale shaker screen and other mesh products are engineered to withstand rigorous conditions, offering extended service life and lower replacement costs.

- Regulatory Compliance: Meeting increasingly strict environmental and safety standards requires advanced filtration capabilities.

- Competitive Advantage: Adopting cutting-edge technology and materials can give your business a significant edge in your respective market.

When considering partnerships, particularly with Chinese manufacturers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, keep these tips in mind:

- Verify Certifications and Quality Control: Ensure manufacturers adhere to international quality standards (e.g., ISO certifications) and have robust QC processes in place for every shale shaker screen produced.

- Assess Customization Capabilities: Look for partners who can offer tailor-made solutions for your specific operational needs, beyond just standard sizes and materials. A strong shale shaker screen factory will offer this.

- Evaluate Technical Support and After-Sales Service: A strong partner provides ongoing support, from product selection to installation and troubleshooting.

- Understand the Shale Shaker Screen Price vs. Value Equation: While cost is important, focus on the total value proposition, including product lifespan, efficiency gains, and reliability, rather than just the lowest initial shale shaker screen price. High-quality shale shaker screen mesh is an investment.

Future-proof strategies involve embracing innovation, prioritizing sustainable solutions, and forging strong, collaborative relationships with manufacturers who are investing in R&D and advanced manufacturing technologies, particularly those from leading centers like shale shaker screen China.

Conclusion: Shaping the Future of Filtration

FILTECH continues to be a pivotal event, shaping the global mud vibrating screen and steel grating market by bringing together innovators, fostering collaboration, and setting new benchmarks for quality and performance. The advancements in filtration media, driven by companies like Anping County Hangshun Wire Mesh Manufacture Co., Ltd and other global leaders, are critical for industries worldwide. For B2B decision-makers, understanding these trends and identifying the right manufacturing partners is key to unlocking future growth and operational excellence.

To explore cutting-edge shale shaker screen solutions and see how Anping County Hangshun can meet your specific industrial filtration needs, we encourage you to:

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025