- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Helideck Perimeter Safety Nets: Robust Stainless Steel Protection

Industry Trends and the Imperative of Helideck Safety

The global offshore energy sector, encompassing oil & gas, wind energy, and maritime logistics, continues its expansion, driving an unparalleled demand for robust safety infrastructure. Helidecks, critical for personnel transfer and emergency services on offshore platforms, vessels, and remote land-based facilities, necessitate the highest safety standards. A paramount component in this safety regimen is the helideck perimeter safety nets, engineered to prevent personnel and equipment falls from helideck edges. The market trend indicates a clear shift towards advanced materials, superior engineering, and strict compliance with international aviation and marine safety regulations, such as those stipulated by the International Civil Aviation Organization (ICAO) Annex 14, Volume II, and various national maritime authorities. The focus is increasingly on maintenance-free solutions, enhanced durability, and sustainable operational lifecycles to minimize downtime and reduce total cost of ownership in harsh marine environments.

Technological advancements in material science, particularly in high-grade stainless steel alloys, have revolutionized the performance and longevity of perimeter safety netting. These developments address the perennial challenges of corrosion, UV degradation, and extreme weather conditions prevalent in offshore and coastal installations. Furthermore, intelligent design methodologies are incorporating modularity and ease of installation, significantly reducing project lead times and associated labor costs. The emphasis is on proactive risk mitigation, ensuring that every helideck, from fixed platforms to floating production storage and offloading (FPSO) units and superyachts, is equipped with reliable perimeter net systems that meet or exceed stringent safety benchmarks.

Technical Specifications and Material Excellence

The performance of any perimeter net is directly correlated with its material composition, design, and manufacturing precision. Our Rope Perimeter Safety Netting utilizes premium-grade materials, predominantly AISI 316 and AISI 316L stainless steel, renowned for their exceptional corrosion resistance, particularly against chlorides found in marine atmospheres. These materials exhibit superior tensile strength and fatigue resistance, crucial for applications subjected to dynamic loading and continuous exposure to environmental stressors.

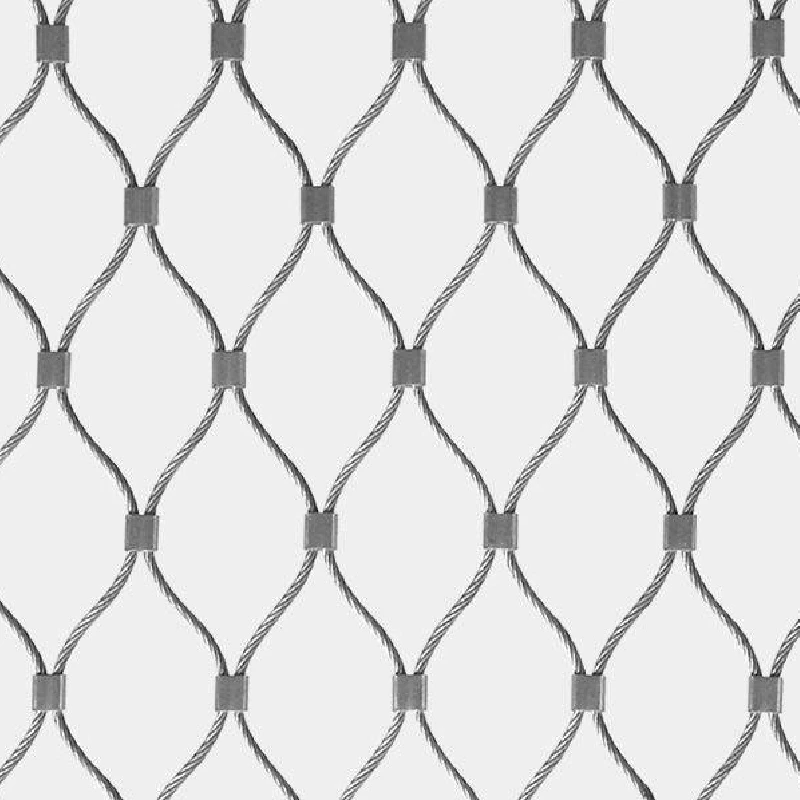

Key technical parameters include wire rope diameter, mesh aperture size, net dimensions, and ultimate breaking strength (UBS). The wire rope construction typically employs a 7x7 or 7x19 strand configuration, offering optimal flexibility and strength. Mesh apertures are meticulously designed to prevent passage of personnel while maintaining aerodynamic stability, typically ranging from 50mm to 100mm. The entire system, including border ropes, thimbles, and ferrules, is fabricated from compatible stainless steel grades to prevent galvanic corrosion and ensure uniform structural integrity.

Product Specification Table: Rope Perimeter Safety Netting

| Parameter | Specification | Description / Standard |

|---|---|---|

| Material | AISI 316 / 316L Stainless Steel | High corrosion resistance, marine grade. |

| Wire Rope Diameter | 1.5mm - 4.0mm (standard) | Customizable based on load requirements. |

| Mesh Aperture (Opening) | 50mm x 50mm to 100mm x 100mm | Optimal fall protection, ICAO compliant. |

| Net Construction | Ferrule-pressed, flexible | Robust, seamless connections for strength. |

| Ultimate Breaking Strength (UBS) | Varies by wire dia. and mesh size | Calculated per international safety factors. |

| Service Life Expectancy | 15-20+ years (typical) | Dependent on environmental conditions and maintenance. |

| Compliance Standards | ICAO Annex 14, CAP 437, IMO, ISO | Adherence to international aviation & maritime safety. |

The selection of wire rope diameter and mesh size is critical and directly impacts the net's load-bearing capacity and personnel fall arrest capabilities. Our nets are designed with a minimum safety factor, often exceeding 5:1, ensuring they can safely absorb dynamic loads. The flexibility of the stainless steel rope allows for effective energy absorption, minimizing injury risk in the event of a fall. All components undergo rigorous material traceability and quality checks to ensure compliance with specifications.

Application Scenarios and Industry Reach

The versatility and critical safety function of perimeter safety netting extend across a broad spectrum of industries where helicopter operations are integral to logistics, emergency response, and personnel transport. Our solutions are deployed in:

- Offshore Oil & Gas Platforms: Providing vital perimeter protection on drilling rigs, production platforms, and living quarters. The corrosive marine environment demands materials with exceptional longevity.

- Offshore Wind Farms: Ensuring safety on transformer stations, crew transfer vessels, and service operation vessels (SOVs) with integrated helidecks.

- Maritime Vessels: Essential for naval ships, coast guard vessels, commercial ferries, luxury yachts, and supply vessels that feature helipads.

- Land-Based Helipads: Including hospital helipads, corporate headquarters, and remote industrial sites where helicopter transport is routine.

- Specialized Applications: Such as temporary helidecks for humanitarian aid missions or military operations, requiring rapid deployment and robust performance.

In each scenario, the objective remains consistent: to provide an impenetrable barrier against falls, thereby protecting lives and preventing costly equipment damage. The design must accommodate the specific wind loading, temperature fluctuations, and operational dynamics of each installation. For example, on floating structures, the perimeter net must withstand constant motion and vibrations without compromising its structural integrity or attachment points. Our expertise ensures that these nuanced requirements are met with precision engineering and high-quality materials.

Technical Advantages of Our Rope Perimeter Safety Netting

Our Rope Perimeter Safety Netting delivers a range of significant technical advantages, setting it apart in the demanding field of helideck safety. These advantages stem from our commitment to advanced material science, precision engineering, and adherence to global safety standards.

- Unparalleled Corrosion Resistance: Utilizing AISI 316/316L stainless steel, our nets offer superior resistance to salt spray, chlorides, and other corrosive agents prevalent in marine and industrial environments. This significantly extends the service life compared to alternative materials or lower-grade stainless steels.

- Exceptional Durability and Longevity: Engineered for a long service life, typically exceeding 15-20 years. The robust wire rope construction and ferrule-pressed connections resist wear, abrasion, and fatigue, minimizing the need for frequent replacement.

- High Strength-to-Weight Ratio: Stainless steel wire rope nets provide formidable strength and impact absorption capabilities while maintaining a relatively low weight, reducing structural load on the helideck and simplifying installation.

- UV and Temperature Stability: Stainless steel is inherently resistant to UV degradation and retains its mechanical properties across a wide range of temperatures, from polar cold to tropical heat, unlike synthetic alternatives which can become brittle or degrade over time.

- Minimal Maintenance Requirements: The intrinsic properties of stainless steel mean these nets require minimal maintenance, largely limited to periodic inspections. This translates into lower operational expenditures and reduced helideck downtime.

- Compliance with International Standards: Designed and manufactured to meet or exceed ICAO Annex 14, CAP 437, and IMO regulations, ensuring global acceptability and the highest level of safety.

- Aesthetics and Visibility: The slender profile of stainless steel wire rope provides excellent transparency, minimizing visual obstruction for pilots during approach and landing, while maintaining an aesthetically pleasing, modern appearance.

These advantages cumulatively result in a cost-effective, highly reliable safety solution that contributes significantly to operational efficiency and personnel protection in critical environments. The long-term savings from reduced maintenance and replacement cycles, coupled with enhanced safety, underscore the value proposition of our helideck perimeter safety nets.

Manufacturing Process Flow and Quality Assurance

The production of high-performance perimeter safety netting involves a meticulously controlled manufacturing process, emphasizing precision, material quality, and adherence to stringent engineering standards. Our process ensures that every net delivered meets the highest benchmarks for safety and durability.

Schematic Process Steps:

- Material Selection & Sourcing:

- Procurement of certified AISI 316/316L stainless steel wire ropes from approved suppliers. Material traceability documentation (e.g., Mill Certificates) is verified for chemical composition and mechanical properties (tensile strength, yield strength).

- Design & Engineering Review:

- Detailed review of customer specifications, helideck dimensions, and relevant industry standards (ICAO, CAP 437, DNV GL, ABS). CAD modeling and finite element analysis (FEA) may be employed for complex designs to optimize load distribution and stress points.

- Wire Rope Cutting & Preparation:

- Precision cutting of stainless steel wire ropes to required lengths for individual mesh elements and border ropes using automated machinery to ensure accuracy and minimize waste.

- Mesh Weaving/Crimping (Ferrule-Pressing):

- The core of the manufacturing process where individual wire ropes are interwoven and secured using high-pressure ferrule pressing (CNC machining for accuracy) to form the specified mesh aperture. This creates robust, permanent connections, ensuring uniform strength throughout the net.

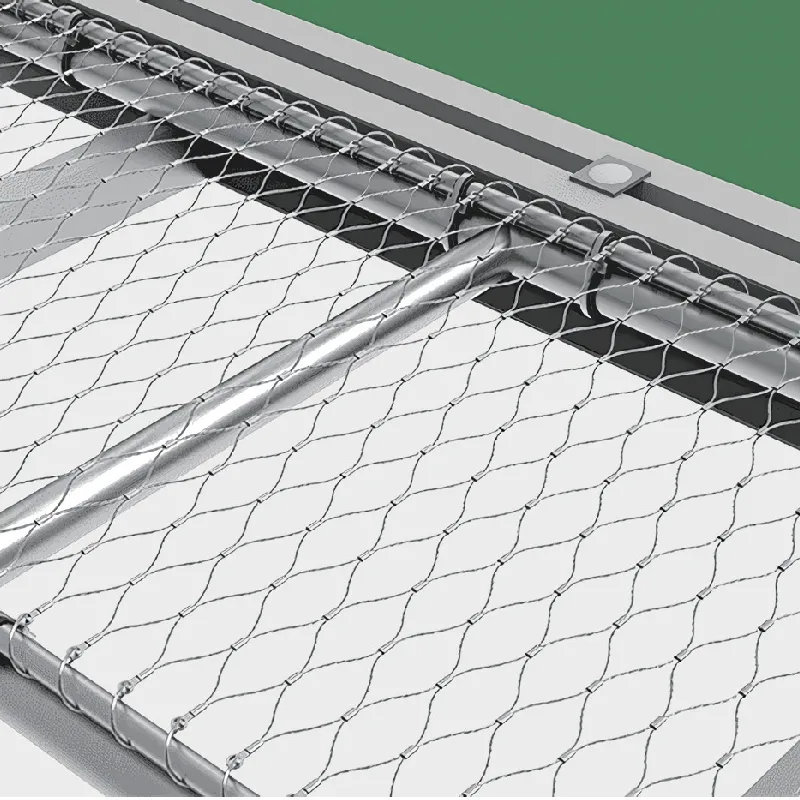

- Border Rope Integration & Edge Finishing:

- The main net body is secured to heavier gauge border ropes, often incorporating thimbles and specialized ferrules at attachment points to distribute load and protect against abrasion. Edges are finished to prevent fraying and ensure a clean, safe perimeter.

- Quality Control & Testing:

- Dimensional Inspection: Verification of overall dimensions, mesh size, and rope diameters.

- Visual Inspection: Checking for defects, consistent crimping, and proper material finish.

- Load Testing (Sample): Destructive and non-destructive load tests on material samples and selected net sections to confirm ultimate breaking strength (UBS) and compliance with design safety factors. (e.g., ISO 2307, ASTM A931 for wire ropes, DNVGL-ST-0377 for offshore applications).

- Material Verification: Positive Material Identification (PMI) may be performed to confirm alloy composition.

- Packaging & Documentation:

- Nets are carefully packaged to prevent damage during transit. Comprehensive documentation, including material certifications, test reports, and installation guides, accompanies each shipment.

This meticulous process flow, coupled with rigorous testing against international standards like ISO and ANSI for materials and structural integrity, ensures that every product represents the pinnacle of safety engineering. Our long-standing commitment to quality and process control minimizes the risk of defects and guarantees a reliable, long-lasting product.

Vendor Comparison: Key Differentiators

Selecting the right vendor for helideck perimeter safety nets is a critical decision impacting safety, longevity, and operational expenditure. While several manufacturers offer perimeter netting solutions, key differentiators lie in material quality, engineering expertise, certification adherence, and commitment to customized solutions. Our firm distinguishes itself through a blend of technical superiority and customer-centric service.

Vendor Comparison Table:

| Feature | Our Company Offering | Typical Competitor Offering |

|---|---|---|

| Primary Material Grade | AISI 316/316L Stainless Steel | AISI 304 Stainless Steel or Galvanized Steel |

| Corrosion Resistance | Excellent (high resistance to chlorides) | Good (lower resistance to chlorides) |

| Manufacturing Process | Precision Ferrule-Pressed (CNC) | Basic Crimping or Knotting |

| Certification & Compliance | ICAO, CAP 437, IMO, ISO 9001, DNV GL/ABS traceability | Basic industry standards; less comprehensive traceability |

| Customization Capability | Full engineering support for bespoke dimensions, attachments | Limited, standard sizes and configurations |

| Warranty Period | Extended (5-10 years on materials & workmanship) | Standard (1-2 years) |

| Project Support | Consultation, design, installation guidance, after-sales | Product delivery only |

Our commitment to using AISI 316/316L stainless steel, coupled with advanced manufacturing techniques, significantly enhances the product's lifespan and reduces lifecycle costs. While initial investment might be slightly higher for premium materials, the long-term benefits in reduced maintenance, fewer replacements, and unparalleled safety assurance provide a superior return on investment. Our comprehensive certification and project support further mitigate risks and streamline implementation for our B2B clients.

Customized Solutions for Unique Requirements

Recognizing that no two helideck installations are identical, we specialize in providing tailored helideck perimeter safety nets solutions. Helideck dimensions, operational environment, existing structural interfaces, and specific regulatory interpretations can vary widely. Our engineering team collaborates closely with clients from the initial design phase to final installation, ensuring the netting system perfectly integrates with the helideck's unique architecture and operational parameters.

- Dimension and Shape Adaptability: From circular helidecks on offshore vessels to rectangular platforms on hospital rooftops, our nets are custom-fabricated to exact dimensions, including irregular shapes or sections requiring cut-outs for equipment.

- Attachment System Design: We develop bespoke attachment hardware and methodologies to integrate with diverse helideck structures, whether bolted, clamped, or welded. This includes custom stanchion designs, tensioning systems, and quick-release mechanisms for emergency access.

- Material and Wire Rope Specification: While AISI 316/316L is standard, specific applications might require adjustments in wire rope diameter or mesh aperture to meet extraordinary load requirements or specialized environmental conditions.

- Environmental Considerations: For extremely harsh environments (e.g., Arctic conditions, high-sulfur regions), specific material coatings or enhanced passivation treatments can be incorporated to further augment corrosion resistance.

- Modular Design for Large Installations: For very large helidecks or complex structures, we can design modular netting sections that facilitate easier installation, inspection, and maintenance, reducing overall operational impact.

Our design process includes detailed engineering drawings, 3D modeling, and consultation with classification societies (e.g., DNV GL, ABS, Lloyd's Register) to ensure full compliance and optimal performance. This bespoke approach guarantees that the safety solution is not merely compliant but also optimized for the specific operational context, maximizing safety and extending asset life.

Application Case Studies and Customer Success

Our reputation is built on successful deployments and the trust of our clients across various demanding industries. Here are illustrative examples of how our helideck perimeter safety nets have provided critical safety solutions:

Case Study 1: North Sea Oil Platform Refit

An offshore oil and gas operator in the North Sea required a complete replacement of their helideck perimeter netting system during a scheduled platform refit. The existing system, made of a lower-grade material, had shown significant signs of corrosion and fatigue after 10 years of service, necessitating costly repairs and posing safety concerns. We provided a custom-engineered solution using AISI 316L stainless steel wire rope netting, designed to withstand the severe wind loads and corrosive conditions of the North Sea. The nets were prefabricated into modular sections, allowing for rapid installation during a narrow weather window. The client reported a significant improvement in perceived safety, simplified maintenance protocols, and an expected service life exceeding 20 years, contributing to a substantial reduction in projected lifecycle costs. Our proactive engineering support and adherence to DNV GL standards were key factors in the project's success.

Case Study 2: Hospital Rooftop Helipad Upgrade

A major metropolitan hospital sought to upgrade its rooftop helipad perimeter safety for enhanced patient and staff safety during air ambulance operations. The challenge involved integrating a robust netting system with an existing concrete structure, requiring minimal disruption to critical hospital services. Our team engineered a lightweight, high-strength stainless steel net system with custom-designed mounting brackets that utilized existing anchor points where possible, minimizing new structural work. The translucent nature of the stainless steel mesh maintained unobstructed views for air traffic control and emergency personnel. The project was completed on schedule, within budget, and passed stringent local aviation authority inspections, significantly improving the helipad's operational safety profile and receiving positive feedback from helipad ground crew regarding ease of operation and maintenance.

Case Study 3: Superyacht Helideck Integration

A prominent superyacht builder required an aesthetically pleasing yet exceptionally robust perimeter safety net for a new luxury vessel's helideck. The primary challenges included precise integration with the yacht's sleek design, minimal visual impact, and full compliance with both ICAO and SOLAS regulations for passenger vessels. Our customized solution featured ultra-fine gauge AISI 316 wire rope netting with polished stainless steel fixtures, ensuring high corrosion resistance in a saltwater environment while maintaining the yacht's luxurious aesthetic. The system was designed for quick deployment and retraction, offering flexibility during different operational modes. The successful implementation underscored our capability to deliver high-performance, visually discreet, and compliant safety solutions even for the most discerning clients.

Frequently Asked Questions (FAQ)

- Q: What is the expected service life of your helideck perimeter safety nets?

- A: Our Rope Perimeter Safety Netting, manufactured from AISI 316/316L stainless steel, is designed for a service life of 15-20+ years under typical operating conditions in marine and industrial environments. This longevity is attributed to superior material selection and robust manufacturing processes.

- Q: Are your nets compliant with international safety standards?

- A: Absolutely. Our products are engineered and tested to meet or exceed relevant international standards, including ICAO Annex 14 Volume II, CAP 437 (Standards for Offshore Helicopter Landing Areas), and various IMO/SOLAS regulations where applicable. We also provide full material traceability and test certifications.

- Q: Can you provide custom sizes and designs for unique helidecks?

- A: Yes, customization is a core service. We excel in designing and fabricating bespoke perimeter netting solutions to fit any helideck dimension, shape, or specific structural interface. Our engineering team works closely with clients to develop optimal solutions.

- Q: What kind of maintenance do the stainless steel nets require?

- A: Due to the inherent corrosion resistance and durability of AISI 316/316L stainless steel, our nets require minimal maintenance. Periodic visual inspections for damage, wear, or loose connections are typically sufficient. Unlike synthetic nets, they do not require UV treatment or extensive cleaning for degradation.

- Q: What is the lead time for an order?

- A: Lead times vary based on the complexity and size of the order. For standard configurations, typically 4-6 weeks from order confirmation to shipment. For highly customized projects, it might range from 8-12 weeks, including design and engineering phases. We always provide a detailed production schedule upon project initiation.

- Q: What warranty is provided with your products?

- A: We offer a comprehensive warranty of 5 to 10 years on materials and workmanship, depending on the specific product and application. This commitment reflects our confidence in the quality and durability of our helideck perimeter safety nets. Full warranty details are provided with each quotation and contract.

- Q: What kind of customer support do you offer post-purchase?

- A: Our customer support extends beyond product delivery. We provide installation guidance, technical documentation, and readily available expert advice for any operational queries or future maintenance needs. Our team is committed to ensuring long-term satisfaction and optimal performance of our safety solutions.

Lead Time, Fulfillment, and Warranty Commitments

We understand the critical nature of project timelines and the importance of reliable delivery in the B2B sector. Our supply chain and manufacturing processes are optimized to ensure efficient fulfillment without compromising on quality.

- Lead Time: For standard configurations and typical project sizes, our lead time generally ranges from 4 to 6 weeks from the receipt of a confirmed order and final specifications. Complex or large-scale customized projects may require 8 to 12 weeks, inclusive of detailed design, engineering, and approval phases. We maintain transparent communication regarding production schedules and milestones throughout the order process.

- Fulfillment & Logistics: Our logistics team coordinates global shipping, ensuring products are delivered safely and efficiently to your specified location, whether an offshore platform, shipyard, or onshore facility. All products are meticulously packaged to protect against transit damage, and comprehensive documentation, including shipping manifests, customs declarations, and installation manuals, is provided.

- Warranty: We stand behind the quality and durability of our Rope Perimeter Safety Netting with an industry-leading warranty. We offer a 5-year warranty on material integrity and workmanship for our standard products, extendable to 10 years for specific project-based solutions and conditions. This warranty covers manufacturing defects and material failures under normal operating conditions. Our commitment ensures peace of mind and protection for your investment.

- Customer Support: Our dedicated after-sales support team is available to assist with any technical queries, provide guidance on installation, maintenance, and inspection, or address any concerns that may arise during the operational lifespan of the helideck perimeter safety nets. We believe in building lasting relationships with our clients through continuous support and service excellence.

Our goal is to provide not just a product, but a complete solution backed by expertise, reliability, and unparalleled customer service, ensuring your helideck operations remain safe and efficient for decades to come.

Conclusion: Setting the Standard for Helideck Safety

The deployment of advanced helideck perimeter safety nets is not merely a regulatory requirement but a fundamental pillar of operational safety in critical industries. Our commitment to utilizing premium-grade materials, employing precision manufacturing techniques, and adhering to rigorous international standards ensures that our Rope Perimeter Safety Netting solutions offer superior durability, corrosion resistance, and unparalleled reliability. By addressing the specific challenges of offshore, maritime, and demanding land-based environments, we provide a product that minimizes risk, reduces maintenance overheads, and guarantees long-term performance.

Through continuous innovation, custom-engineered solutions, and a steadfast dedication to customer satisfaction, we empower our clients to achieve the highest levels of safety and operational efficiency. Partner with us for robust helideck safety infrastructure that protects personnel and assets, now and for the future.

References

- International Civil Aviation Organization (ICAO). (2013). Annex 14, Volume II – Aerodromes: Heliports. Montréal, Canada.

- Civil Aviation Authority (CAA). (2020). CAP 437: Standards for Offshore Helicopter Landing Areas. Thirteenth Edition. London, UK.

- DNV GL. (2016). DNVGL-ST-0377: Helideck Safety and Operations. Høvik, Norway.

- International Maritime Organization (IMO). (2000). International Convention for the Safety of Life at Sea (SOLAS). London, UK.

- American Society for Testing and Materials (ASTM). (2015). ASTM A931: Standard Test Methods for Load-Controlled Fatigue Testing and Flexural Fatigue Testing of Steel Wire Ropes for the Production of Wire Rope for Naval Aircraft. West Conshohocken, PA.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025