- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Premium Shaker Screen for Sale - High Performance Industrial Screening

Navigating Excellence: Top Mud Vibrating Screen & Steel Grating Manufacturers from China at FILTECH

Discovering leading innovations in industrial filtration and material separation.

Introduction: The Global Stage for Filtration Innovation

FILTECH, the world's largest filtration event, consistently serves as the premier nexus for innovation, technology exchange, and business development in the industrial filtration and separation sector. For B2B decision-makers seeking cutting-edge solutions, this exhibition is more than just a gathering; it's a critical barometer for emerging trends and a direct gateway to the leading minds and manufacturers shaping our industries.

In the specialized realms of mud vibrating screens and steel gratings, FILTECH provides an unparalleled platform. These components are fundamental to countless industrial processes, from oil and gas drilling – where high-efficiency shaker screens are indispensable for drilling mud solids control – to mining, water treatment, and infrastructure. The ability to effectively separate solids from liquids, manage waste, and ensure structural integrity hinges on the quality and performance of these vital products.

China, a global manufacturing powerhouse, has steadily grown its influence in the high-performance filtration and wire mesh industry. Its manufacturers, often equipped with advanced production capabilities and a keen eye for material science, are increasingly becoming go-to partners for businesses worldwide. At FILTECH, Chinese shaker screen manufacturers and steel grating specialists showcase innovations that drive efficiency, reduce costs, and meet stringent global standards, making them key players for any company looking for a reliable industrial shaker screen solution or durable steel grating for their operations.

Industry Trend Spotlight: The Evolution of Filtration & Separation

The filtration and separation industry is experiencing a transformative period, driven by a confluence of technological advancements, environmental imperatives, and escalating industrial demands. Several key trends are gaining significant global attention:

- Development of High-Performance Filtration Media: The push for greater efficiency and finer separation has led to innovations in materials and weave patterns. This includes multi-layered shaker screens designed for extended lifespan and superior cut points in mud solids control, as well as advanced filter elements capable of handling aggressive chemicals and extreme temperatures.

- Demand for Custom-Engineered Mesh Solutions: Generic solutions are no longer sufficient. Industries require mesh products tailored to specific particle sizes, flow rates, and operational environments. This customization extends to the design of industrial shaker screens, ensuring optimal performance for diverse drilling applications and processing needs.

- Increased Focus on Corrosion Resistance and High-Temperature Performance: Harsh operating conditions in sectors like chemical processing, power generation, and oil & gas necessitate materials that can withstand corrosive agents and elevated temperatures, ensuring longevity and safety.

- Adoption of Advanced Manufacturing Techniques for Complex Filter Elements: Precision manufacturing, including laser cutting, welding, and 3D printing, allows for the creation of intricate and highly efficient filter designs, enhancing both performance and structural integrity.

Market data underscores this growth trajectory. The global industrial filtration market is experiencing steady growth, driven by increasing industrialization, stringent environmental regulations, and rising demand from the petrochemical, water treatment, and pharmaceutical sectors. There's a particular emphasis on high-efficiency and durable filtration systems, with analysts projecting continued expansion as industries seek to optimize processes and meet sustainability goals. The market for products like quality shaker screen for sale continues to see robust demand due to these underlying industrial growth factors.

Emerging focus areas include sustainable filtration technologies that minimize waste and energy consumption, the development of advanced materials for extreme conditions, and the integration of energy-efficient separation technologies. Moreover, the demand for custom-engineered mesh solutions is on the rise, alongside an increasing interest in smart process optimization through sensor integration and data analytics, revolutionizing how filtration systems operate.

Profiles of Leading Companies: Innovators in Filtration and Grating

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

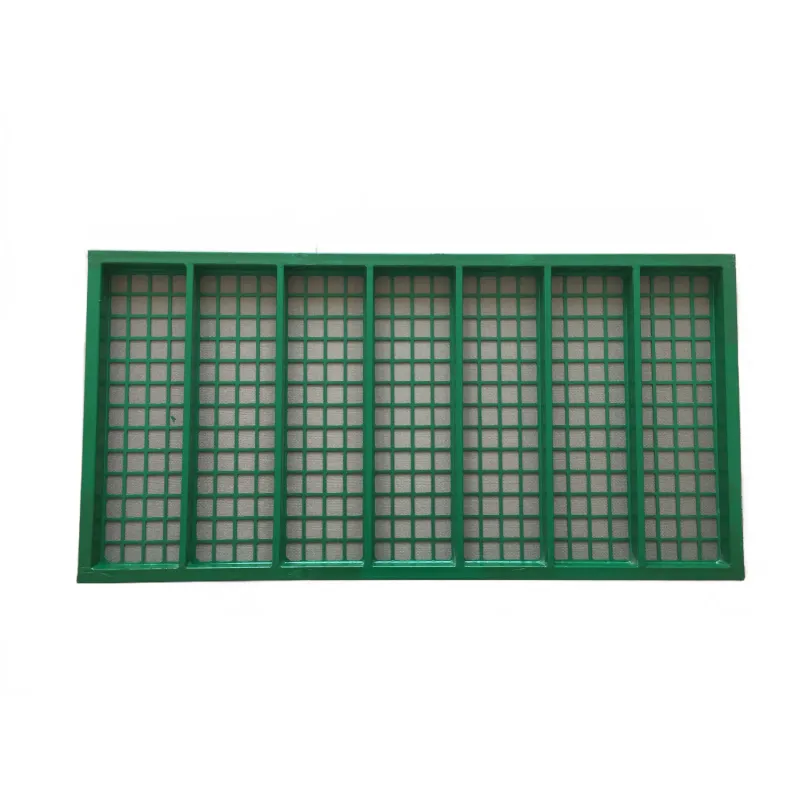

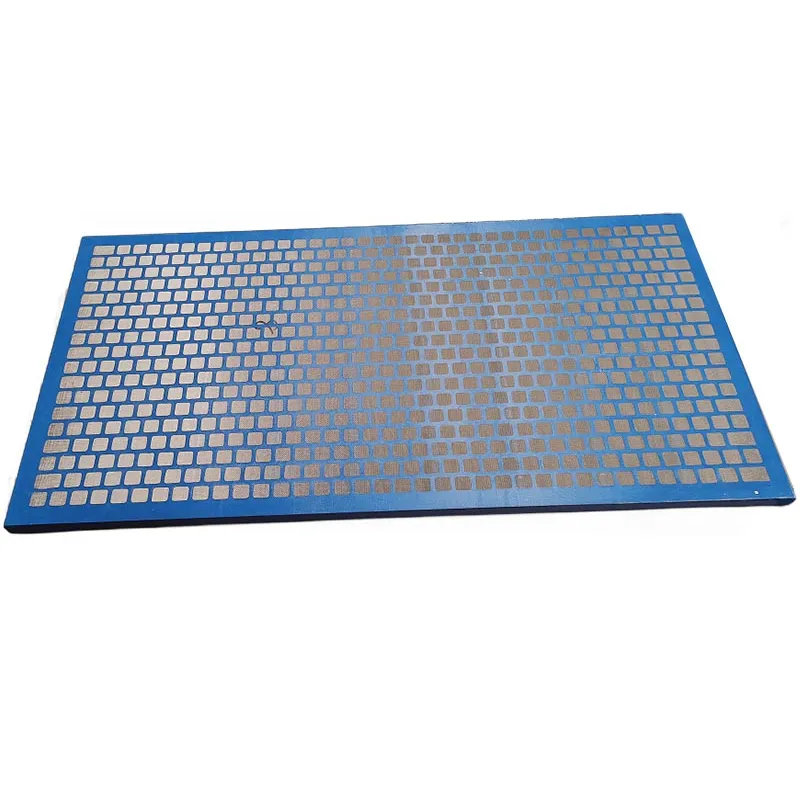

A prominent name among shaker screen manufacturers, Anping County Hangshun Wire Mesh Manufacture Co., Ltd stands out for its profound specialization in high-quality industrial wire mesh and sintered filter elements. Located in the heart of China's wire mesh industry, Hangshun has built a reputation for delivering robust and reliable filtration solutions designed for demanding industrial applications. Their expertise spans a wide range of products crucial for efficient separation, particularly their acclaimed shaker screen offerings.

What truly sets Hangshun apart is their extensive custom fabrication capabilities. Recognizing that every client's needs are unique, they excel at engineering tailor-made solutions, from custom industrial shaker screens to specialized steel gratings that meet precise specifications for size, material, and performance. This client-centric approach, combined with a strong focus on applications in demanding sectors like oil & gas, chemical processing, and mining, makes them a trusted partner globally.

Their commitment to material science and product performance is evident in their rigorous quality control and continuous investment in R&D. When seeking a dependable shaker screen for sale, Anping County Hangshun Wire Mesh Manufacture Co., Ltd offers a compelling blend of quality, customization, and technical support that directly addresses the challenges faced by B2B decision-makers. Their ability to produce durable and highly efficient mud vibrating screens and steel gratings ensures optimal operational efficiency and extended equipment lifespan for their clients.

Other Global Leaders to Watch:

- GKD – Gebr. Kufferath AG (Germany): Renowned for its metal weaves and industrial mesh solutions, GKD offers innovative products for filtration, architectural applications, and process belt technology. Their engineering prowess is a benchmark in the industry.

- Sefar AG (Switzerland): A global leader in precision fabrics, Sefar produces technical textiles for various filtration, screen printing, and architectural applications. Their focus on high-performance monofilament and multifilament fabrics is critical for advanced separation processes.

- Bopp & Co. AG (Switzerland): Specializing in precision woven wire mesh, Bopp delivers high-quality solutions for demanding industrial applications. Their expertise in fine mesh and customized fabrications serves a wide array of filtration needs.

- W. S. Tyler, Inc. (USA): With a long history in particle analysis and industrial wire cloth, W. S. Tyler is recognized for its testing sieves, laboratory equipment, and engineered mesh products, including those used in vibrating screen applications.

- Cambridge Engineered Solutions (USA): A leader in metal conveyor belts and wire cloth, Cambridge offers robust solutions for high-temperature and heavy-duty applications, essential for processing and filtration in harsh environments.

Market Outlook & Opportunities: Charting the Future of Filtration

The future of the mud vibrating screen and steel grating market is characterized by several dynamic trends and evolving buyer demands. Industries are increasingly seeking not just products, but comprehensive solutions that deliver enhanced performance, greater longevity, and a lower total cost of ownership. Upcoming trends include a stronger emphasis on:

- Intelligent Filtration Systems: Integration of sensors and IoT capabilities into industrial shaker screens and other filtration equipment for real-time monitoring of performance, clogging, and wear, enabling predictive maintenance and optimized operational efficiency.

- Sustainability-Driven Innovations: Demand for products manufactured from recycled materials, energy-efficient designs, and filtration media that can be regenerated or have a reduced environmental footprint.

- Material Advancements: Continuous development of new alloys, composites, and surface treatments for steel gratings and mud vibrating screens to provide superior resistance to corrosion, abrasion, and extreme temperatures, extending product life and reducing replacement frequency.

- Modular and Scalable Solutions: A preference for filtration and separation systems that can be easily adapted or expanded to meet changing production demands without significant capital expenditure.

Significant opportunities lie in the intersection of traditional manufacturing with cutting-edge technologies. Automation in the production of wire mesh and steel gratings ensures precision and consistency, reducing human error and boosting output. Smart manufacturing, leveraging AI and machine learning, can optimize mesh design for specific applications, predict material performance, and enhance supply chain efficiency for products like shaker screen for sale. Furthermore, the global push towards sustainability opens doors for manufacturers who can offer eco-friendly production processes and products that support a circular economy.

For buyers, this translates into a market rich with innovation. The ability to source durable, high-efficiency mud vibrating screens and robust steel gratings, often custom-engineered, is becoming easier with advancements by leading shaker screen manufacturers. The focus is shifting towards integrated solutions that not only perform well but also contribute to the overall operational intelligence and environmental responsibility of an enterprise.

Buyer/Business Takeaways: Strategic Investments for the Future

For B2B decision-makers, understanding these market dynamics is crucial for making informed investment choices. Investing in high-quality mud vibrating screens and steel gratings isn't just about procurement; it's about securing operational efficiency, safety, and long-term cost savings. Here’s why it makes strategic sense:

- Enhanced Operational Efficiency: Superior shaker screens ensure more effective solids control, leading to cleaner drilling fluids, reduced waste, and improved drilling rates. High-grade steel gratings provide safer work platforms and reliable structural support, minimizing downtime and maintenance.

- Durability and Longevity: Investing in products from reputable shaker screen manufacturers, crafted from advanced materials, means greater resistance to wear, corrosion, and fatigue, significantly extending service life and reducing replacement costs.

- Compliance and Safety: High-quality components help meet stringent industry regulations and safety standards, mitigating risks and ensuring a compliant operational environment.

- Cost-Effectiveness in the Long Run: While initial investment might seem higher for premium products, the benefits of reduced maintenance, increased efficiency, and extended lifespan translate into substantial long-term savings.

When considering adoption or partnership with Chinese manufacturers for your industrial shaker screen or steel grating needs, consider these tips:

- Thorough Due Diligence: Research potential partners extensively, focusing on certifications (ISO, API), production capabilities, and client testimonials. Manufacturers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd often provide detailed product specifications and quality assurance documentation.

- Focus on Customization Capabilities: Look for manufacturers who can offer tailored solutions that precisely match your application's unique requirements, from mesh size to material composition and frame design for your specific shaker screen.

- Prioritize Quality Control: Understand their internal QC processes, testing methodologies, and how they ensure consistent product quality from batch to batch.

- Establish Clear Communication Channels: Effective communication is key to successful international partnerships, ensuring specifications are understood and timelines are met.

To future-proof your strategies, embrace innovation. Look for manufacturers who are not only producing reliable current-generation products but also investing in R&D for next-generation materials and smart technologies. Partnering with companies that align with your long-term goals for efficiency, sustainability, and technological advancement will be critical in navigating the evolving industrial landscape.

Conclusion: Shaping the Future Together

FILTECH remains the quintessential platform for exploring the cutting edge of industrial filtration. It plays an indispensable role in shaping the global mud vibrating screen and steel grating market, bringing together innovators, suppliers, and buyers from across the globe. The advancements showcased here, particularly by leading Chinese shaker screen manufacturers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd, highlight a future where efficiency, durability, and technological integration are paramount.

For businesses aiming to enhance their operational performance with superior filtration and separation solutions, the choice of a manufacturing partner is critical. Whether you're seeking a reliable shaker screen for sale, a custom industrial shaker screen, or robust steel grating, the insights and opportunities presented at events like FILTECH are invaluable.

Ready to elevate your industrial operations with high-performance filtration and separation solutions?

Visit Anping County Hangshun Wire Mesh Manufacture Co., Ltd to Learn MoreExplore our range of steel frame shale shaker screens and other industrial mesh products designed for peak performance and longevity.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025