- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

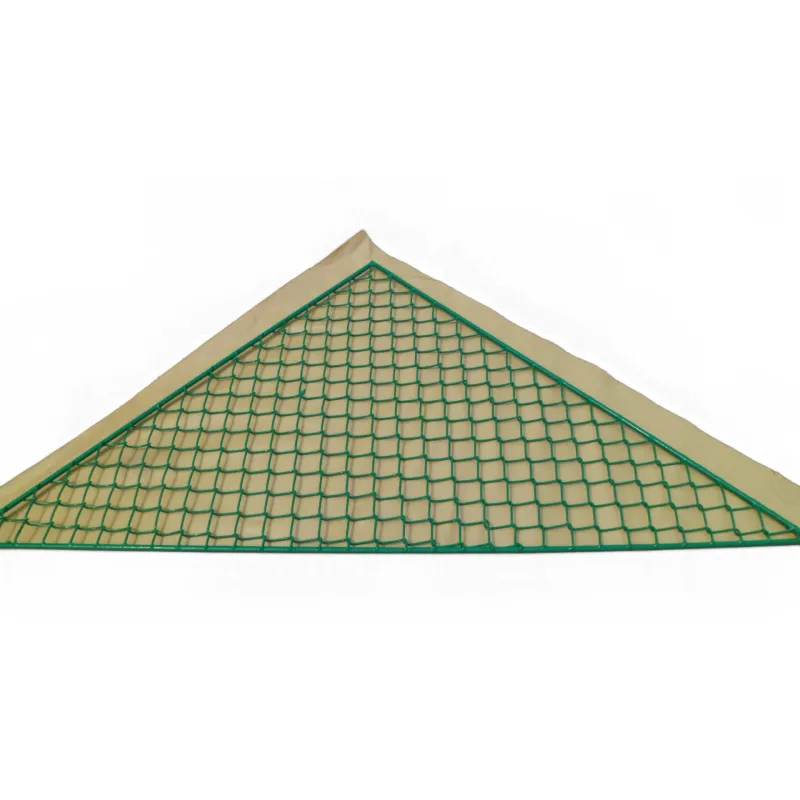

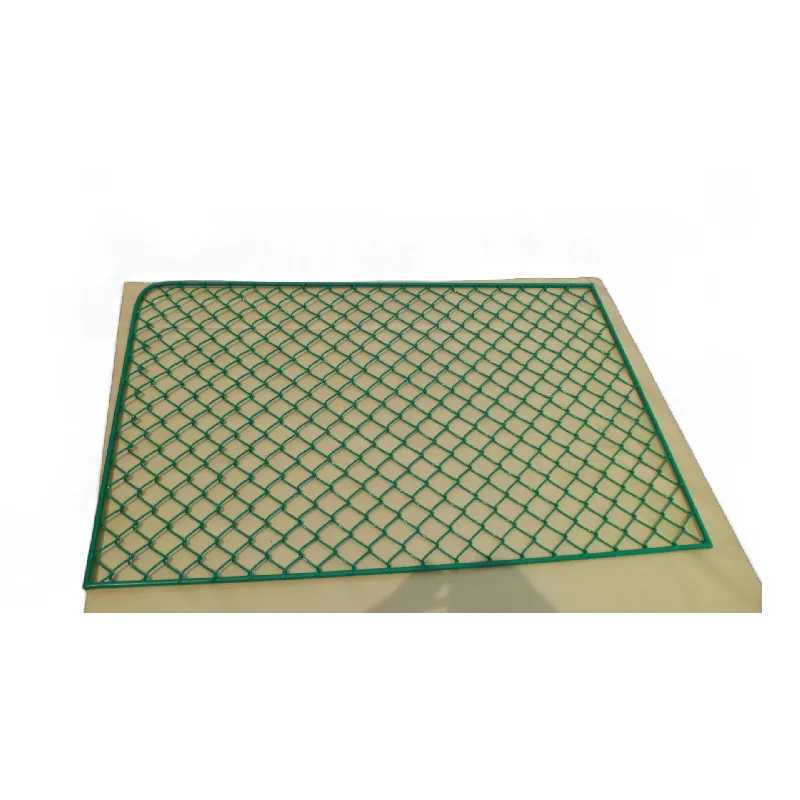

Perimeter Net | Heavy-Duty UV-Stable Safety Netting

perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net is a key solution in the Safety and Security industry, specifically within Industrial safety equipment and Fall prevention equipment. This article explores how Anping County Hangshun Wire Mesh Manufacture Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net Overview

- Benefits & Use Cases of perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net in Fall prevention equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Safety and Security

- Conclusion on perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net Overview

A perimeter net—often referred to as perimeter netting or a perimeter safety net—is an engineered barrier that prevents falls, stops debris, and defines safe zones around elevated platforms, rooftops, helidecks, scaffolds, and industrial walkways. In helipad environments, chain link helipad perimeter safety netting adds critical edge protection and helps mitigate rotor wash hazards by creating a robust, visible boundary.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd designs and manufactures perimeter safety solutions for demanding industrial settings. Typical specifications include hot-dip galvanized carbon steel or stainless steel (304/316) chain link mesh, with wire diameters commonly in the 3.0–5.0 mm range and mesh apertures tailored to site risk and visibility needs. Edges can be finished with reinforced selvedge, hem ropes, tension wires, and purpose-built frames. Surface treatments like galvanizing and optional PVC coating enhance corrosion resistance and service life, especially in coastal, offshore, and high-humidity locations.

From petrochemical plants to rooftop helipads, Hangshun’s perimeter netting systems are engineered for high tensile strength, impact resistance, and reliable performance. As a manufacturer, the company supports full-cycle delivery: design assistance, material selection, prefabricated panelization, and on-site installation guidance to help EHS and engineering teams meet internal safety protocols and applicable guidelines.

Benefits & Use Cases of perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net in Fall prevention equipment

Perimeter safety net systems deliver multi-layer protection in fall prevention programs. On helipads—offshore platforms, hospitals, commercial towers—chain link helipad perimeter safety netting offers a sturdy, low-deflection barrier around the deck, helping prevent personnel and equipment from being displaced by wind or rotor wash. In industrial facilities, perimeter netting secures mezzanines, conveyor walkways, material loading bays, scaffolding edges, and temporary work zones, reducing fall incidents and dropped-object risks.

Key advantages for B2B buyers include customization, durability, and installation efficiency. Hangshun’s perimeter net solutions can be tailored for height, mesh gauge, aperture, and finish to match hazard levels and environmental exposure. Stainless steel 316 is recommended for marine and offshore applications; galvanized or PVC-coated steel serves well for most land-based projects. Prefabricated panels, standardized mounting hardware, and tensioning accessories accelerate installation while achieving consistent line tension and neat alignment.

For decision makers overseeing multi-site portfolios, standardizing on Hangshun’s perimeter netting helps unify safety specifications, streamline maintenance, and simplify spare parts management. The company’s technical team supports drawings, job-site measurements, and compatibility with existing guardrails or support frames, which shortens project lead time from submittal to commissioning.

Cost, Maintenance & User Experience

Total cost of ownership improves when perimeter netting is specified for the operating environment. Galvanized chain link offers a cost-effective balance of strength and longevity for inland facilities, while stainless steel 304/316 maximizes corrosion resistance in harsh or marine settings and reduces replacement cycles. PVC-coated options add aesthetic uniformity and extra protection where visibility and branding are priorities.

Maintenance is straightforward: routine visual inspections (e.g., quarterly or per site policy) for tension, fastener integrity, corrosion points, and impact damage; periodic retensioning where required; and localized repairs using lacing wire or replacement of modular panels. These tasks can typically be performed without specialized tools, minimizing downtime. Many industrial customers value the ability to replace a single panel rather than an entire run, which keeps budgets predictable and assets in service.

Feedback from safety managers and facility engineers frequently highlights quick install times, solid tactile rigidity, and consistent quality control. Working with Anping County Hangshun Wire Mesh Manufacture Co., Ltd, buyers gain access to detailed submittals, packing lists, and installation guidance that help contractors deliver on schedule and within scope—supporting a clear ROI through reduced incidents and extended service life.

Sustainability & Market Trends in Safety and Security

Safety and Security markets are prioritizing durable, recyclable materials and lifecycle efficiency. Metal-based perimeter net systems—galvanized and stainless steel—are fully recyclable and compatible with long-life maintenance strategies, reducing waste and embodied carbon over time. Modular, repairable designs keep systems in the field longer, while protective coatings and stainless alloys minimize replacements in aggressive environments.

Regulatory expectations continue to tighten across construction, energy, aviation, and logistics. Perimeter safety netting can be configured to align with prevailing fall protection guidelines and helipad advisory frameworks, supporting compliance pathways when combined with site-specific risk assessments. Demand is rising for rooftop and urban helipads, offshore energy infrastructure, and high-bay warehousing—all scenarios where robust perimeter netting helps mitigate fall risk and dropped objects.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd invests in high-grade raw materials, surface treatments, and process controls to deliver consistent quality with an eye toward sustainability. Optimized packaging, precise takeoffs, and panel prefabrication help reduce transport volume and on-site waste, while technical support ensures right-first-time installation—a practical, eco-conscious approach for modern safety programs.

Conclusion on perimeter net,perimeter netting,chain link helipad perimeter safety netting,perimeter safety net from Anping County Hangshun Wire Mesh Manufacture Co., Ltd

For B2B leaders seeking reliable fall prevention, perimeter net, perimeter netting, chain link helipad perimeter safety netting, and perimeter safety net solutions from Anping County Hangshun Wire Mesh Manufacture Co., Ltd deliver strength, configurability, and long-term value. Backed by engineering support and robust materials, these systems help standardize safety across facilities and helipad operations with confidence.

Contact us: email: sales@hfpetromesh.com

Visit our website: https://www.hfpetromesh.com

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025