- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

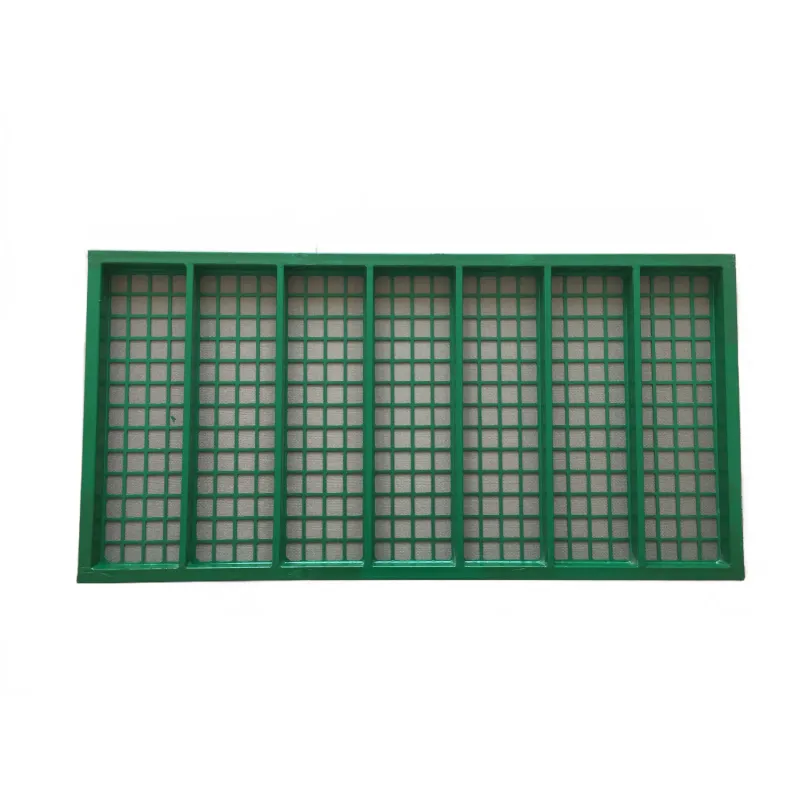

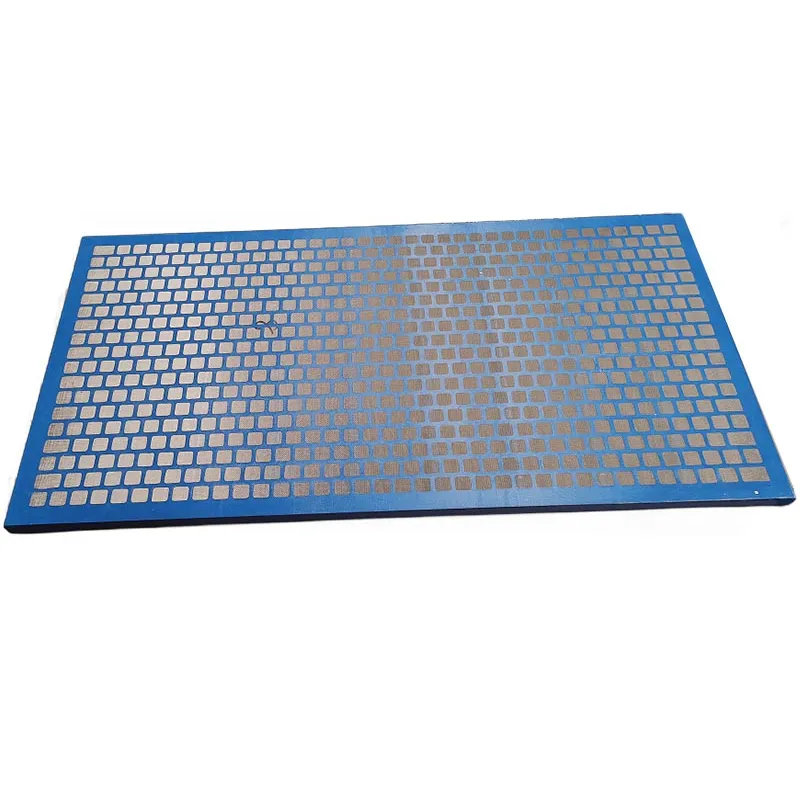

Shaker Screen for Sale - Durable, API-Rated, Fast Shipping

Steel Frame Shale Shaker Screen: Insider Notes, Real Specs, and What Buyers Actually Ask

If you’re scouting a Shaker Screen For Sale, you’re probably juggling API designations, mesh layers, and delivery timelines while your rig crew begs for something that lasts. I’ve been on enough yards to know: the best screen is the one that quietly survives a week of gumbo without drama.

What’s Trending in Screens (and why steel frames are back in vogue)

Two things are obvious in the field right now: operators want predictable API RP 13C labeling and fewer surprise tears. Steel-framed panels—especially those with pre-tensioned multi-layer SS304/SS316 meshes—are popular again. Not because they’re fancy, but because they’re strong, repairable, and easy to source fast from Hebei’s Anping manufacturing hub (the Industrial zone, South of Anping Town, Hengshui, Hebei, China—where this model comes from).

Product Snapshot

Steel Frame Shale Shaker Screen—built for oil and gas drilling, weighted muds, and solids control service. Many customers say conductance is consistent run-to-run, which, frankly, is what keeps mud engineers calm.

Core Specifications (typical values)

| Frame | Welded steel frame with ribbed support; epoxy-bonded mesh |

| Mesh material | SS304/SS316 multi-layer (2–3 layers) |

| API designation | API 20–325 (per API RP 13C) |

| D100 separation | ≈ 73–780 μm (model dependent) |

| Conductance | ≈ 1.2–6.5 kD/mm (real-world use may vary) |

| Non-blanked area | Up to ≈ 4.5–6.8 ft² depending on deck size |

| Dimensions | Common panels for Brandt®, Swaco®, Kemtron®, FSI® shaker footprints |

| Gasket/seal | NBR or PU perimeter gasket |

| Service temperature | Up to ≈ 120–150°C (mud chemistry dependent) |

| Expected service life | ≈ 40–120 rig hours in typical WBM; 30–90 in OBM, depending on solids loading |

How It’s Made (quick process flow)

- Materials: Q235 or equivalent steel frame; SS304/316 wire cloth; epoxy/PU bonding; NBR gasket.

- Methods: frame welding, surface prep, multi-layer pre-tensioning, epoxy bonding, curing, gasket fitment.

- Testing: API RP 13C D100 and conductance; mesh tension test; ASTM B117 salt-spray on coated frames; abrasion checks (ASTM G65 style).

- QC: dimensional gauge checks; deck fit test; leak test around perimeter seals.

Where It Works Best

- Oil and gas drilling shakers (surface hole to production hole).

- Workover rigs and HDD river crossings where fine solids control matters.

- Weighted muds with barite—screens hold up well when conductance stays consistent.

Why buyers pick this over others

Stronger steel support, decent filtering, and reasonable pricing. Honestly, the advantage is boring reliability. Less re-screening in the middle of the night.

Vendor Comparison (typical options I see)

| Vendor | API Range | Mesh Type | Lead Time | Certs | Notes |

|---|---|---|---|---|---|

| HF Petro Mesh (Anping) | 20–325 | SS304/316, multi-layer | ≈ 7–15 days | ISO 9001 | Strong steel frame value |

| Brand Local Dealer | 40–230 | Stainless + composite | Stock/Next-day | API 13C label | Fast but pricey |

| Regional Fabricator | 60–200 | SS304 | ≈ 10–20 days | ISO 9001 (varies) | Limited sizes |

Customization You Can Request

- API cuts matched to your mud rheology map.

- SS316 for aggressive OBM chemistry.

- Reinforced perimeter for high-G shakers.

- Logo printing, palletization, and set-kitting per rig.

Field Result (quick case)

West Texas, 12.6 ppg WBM, high sand. Switching to this steel-frame model (API 140 top deck) cut dilution by ≈ 11% and extended average panel life from ~46 to ~68 hours. The mud man told me—half joking—that the night tour finally stopped nagging him. Not bad.

Quality and Compliance

API RP 13C-compliant labeling for D100 and conductance. Factory QA typically follows ISO 9001 methods; frames see salt-spray checks (ASTM B117) and abrasion benchmarking (ASTM G65 style). In practice, what matters is repeatability—and this line holds up well.

If you need a dependable Shaker Screen For Sale with steady supply out of Hebei, this steel-frame build is an easy recommendation. And yes, it ships crated properly—nobody wants a bent corner showing up on spud day.

References

- API RP 13C: Recommended Practice on Drilling Fluids Processing Systems and Equipment.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM G65: Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus.

- ISO 9001: Quality management systems — Requirements.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025