- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Metal Grating for Sale | Buy Durable Steel Grating & Custom Options

Navigating Innovation: Top Chinese Manufacturers of Mud Vibrating Screens and Steel Gratings at FILTECH

The global industrial landscape is constantly evolving, driven by an insatiable demand for efficiency, durability, and specialized performance. At the forefront of this evolution stands FILTECH – the world's largest and most important filtration event. It serves as a critical nexus for leading manufacturers, innovators, and B2B decision-makers seeking advanced industrial filtration solutions and robust wire mesh products. For sectors heavily reliant on precise separation and reliable structural support, such as the petrochemical, mining, and construction industries, FILTECH offers an unparalleled opportunity to discover the future of mud vibrating screens and steel grating technology. This event is not just a showcase; it's a vital platform where the latest advancements in materials, design, and manufacturing converge, offering immense value to businesses looking to optimize their operations and secure superior industrial components.

Chinese manufacturers, in particular, have emerged as key players, consistently pushing the boundaries of what’s possible in industrial filtration and structural materials. Their presence at FILTECH underscores their commitment to global standards, innovation, and competitiveness, making them indispensable partners for businesses worldwide.

Industry Trend Spotlight: The Ascent of High-Performance Filtration and Robust Grating Solutions

The filtration and industrial materials sectors are experiencing dynamic growth, propelled by several key trends gaining global attention. The development of high-performance filtration media, essential for applications ranging from fine particle separation in pharmaceuticals to heavy-duty mud vibrating screen operations in mining, is paramount. Simultaneously, there's an increasing demand for custom-engineered mesh solutions tailored for specific, often extreme, applications. This includes specialized types of steel grating designed for corrosive environments or areas requiring exceptional load-bearing capacity.

A heightened focus on corrosion resistance and high-temperature performance is critical, especially in sectors like oil & gas and chemical processing, where material failure can have catastrophic consequences. Furthermore, the adoption of advanced manufacturing techniques for complex filter elements and intricate metal grating for sale is revolutionizing product capabilities, leading to more durable, efficient, and precise components.

Market data consistently points to a steady growth trajectory for these industries, driven by increasing industrialization across emerging economies, stringent environmental regulations necessitating better filtration, and rising demand from the petrochemical, water treatment, and pharmaceutical sectors. There’s a particular emphasis on high-efficiency and durable filtration systems, where innovation in mesh and grating design translates directly into operational savings and enhanced safety. The global filtration market, for instance, is projected to continue its robust expansion, with compound annual growth rates reflecting its indispensable role in modern industry.

Emerging focus areas include sustainable filtration solutions that minimize waste and energy consumption, the integration of advanced materials for extreme operating conditions (e.g., lightweight composites, specialized alloys), and the development of energy-efficient separation technologies. Beyond filtration, the market for structural materials like steel grating is seeing a surge in demand for custom-engineered solutions that offer superior strength-to-weight ratios and extended service life. Smart process optimization, leveraging IoT and AI, is also beginning to transform how these components are manufactured and integrated, promising greater customization and predictive maintenance capabilities.

Profiles of Leading Chinese Manufacturers and Global Innovators

Anping County Hangshun Wire Mesh Manufacture Co., Ltd

Hailing from the "Home of Wire Mesh" in China, Anping County Hangshun Wire Mesh Manufacture Co., Ltd stands out as a preeminent provider of high-quality industrial wire mesh and sintered filter elements. Their expertise is particularly vital in applications requiring precision and durability, making them a go-to source for businesses looking to buy steel grating or specialized filtration products.

Hangshun's strength lies in its extensive custom fabrication capabilities, allowing them to produce tailor-made solutions for even the most challenging industrial requirements. Whether it’s intricate woven meshes for fine filtration or robust carbon steel grating for heavy-duty platforms, their commitment to material science and product performance is evident in every offering. They specialize in serving demanding sectors such as oil & gas, chemical processing, and mining, where their products, including components for mud vibrating screens and various types of steel grating, are essential for operational integrity and safety. Their dedication to quality control and innovation ensures that clients receive not just products, but solutions built to last and perform under extreme conditions. For those seeking reliable suppliers of metal grating for sale or custom wire mesh, Hangshun represents a trusted partner.

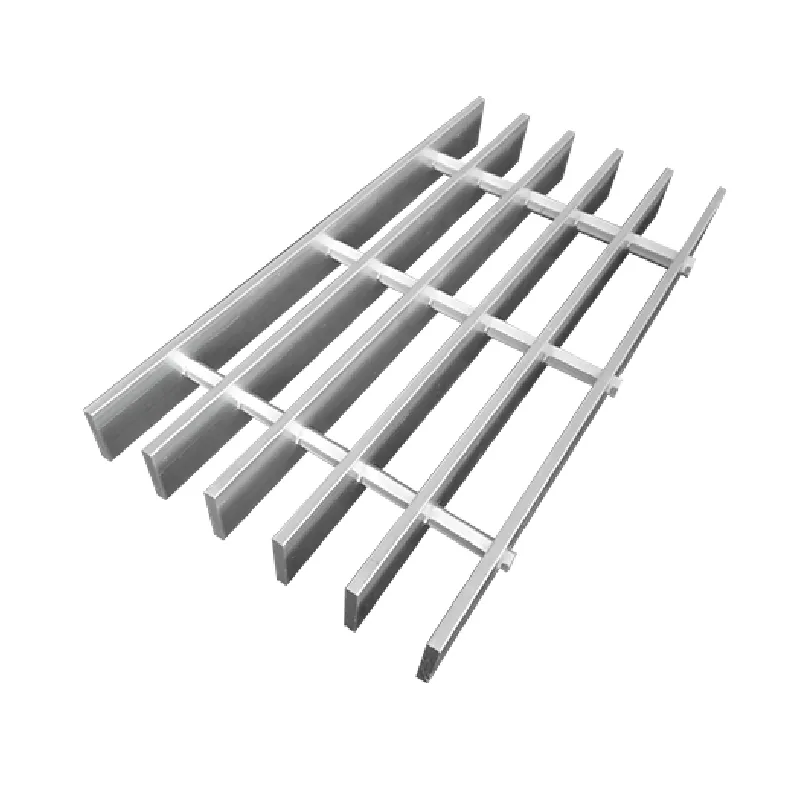

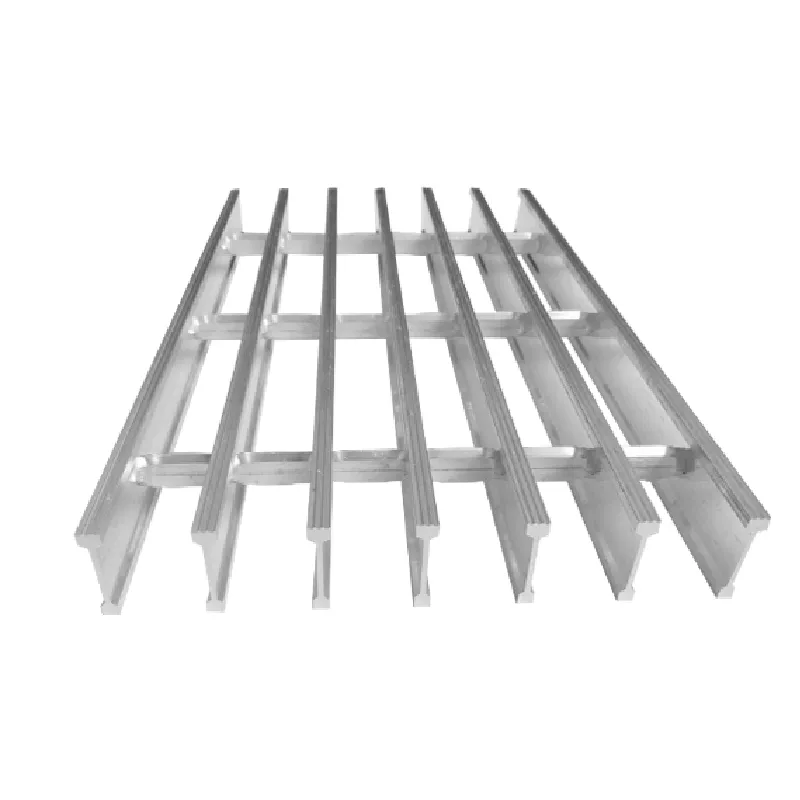

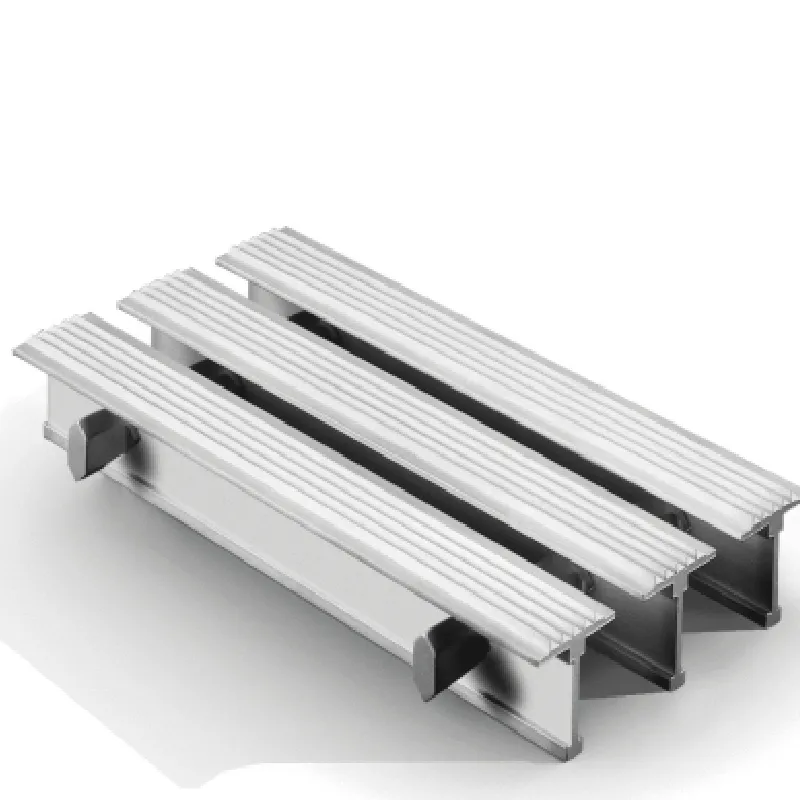

High-strength Swage Locked Grating

Precision-engineered Steel Grating

Industrial-grade Grating Solutions

Durable Swage Locked Grating

Other Global Innovators in Filtration and Mesh Technology:

- GKD – Gebr. Kufferath AG: A German leader known for innovative technical weaves, including metal mesh for architectural and industrial applications, and advanced process belt technology.

- Sefar AG: A Swiss company specializing in precision fabrics from monofilaments, serving diverse industries from filtration and separation to screen printing.

- Bopp & Co. AG: Another prominent Swiss manufacturer, recognized for high-quality woven wire mesh and wire cloth used in a wide range of industrial applications.

- W. S. Tyler, Inc.: An American company with a long history, providing industrial woven wire mesh, vibrating screens, and screening machines for various material processing needs.

- Cambridge Engineered Solutions: A global expert in metal conveyor belts and woven wire mesh products, providing solutions for challenging high-temperature and heavy-load applications.

These companies, alongside Chinese innovators like Anping County Hangshun, collectively drive the global market forward, setting benchmarks for quality, performance, and application diversity in the fields of industrial filtration and structural mesh.

Market Outlook & Opportunities: The Future of Industrial Components

The market for high-performance industrial components, including mud vibrating screens and steel grating, is poised for significant growth driven by several upcoming trends and persistent buyer demand. Automation and smart manufacturing are no longer futuristic concepts but essential tools for increasing production efficiency, reducing waste, and ensuring consistent product quality. This translates into a demand for components that can integrate seamlessly into automated systems, requiring higher precision and reliability.

Sustainability is another dominant force shaping buyer priorities. Industries are increasingly seeking filtration and structural solutions that contribute to a smaller environmental footprint – from energy-efficient mud vibrating screens that optimize material separation with less power, to durable types of steel grating made from recycled materials or designed for extended lifecycles, reducing the need for frequent replacements. There’s a growing appetite for products that offer both superior performance and ecological benefits.

Opportunities abound in the development of advanced materials, particularly for extreme conditions. This includes specialized alloys for carbon steel grating that withstand harsh chemicals or high temperatures, and innovative mesh composites for filtration media that offer enhanced flow rates and longer service intervals. The convergence of material science with digital manufacturing opens new avenues for customization and rapid prototyping, allowing manufacturers to respond swiftly to evolving market needs and provide bespoke solutions for unique industrial challenges.

Buyer/Business Takeaways: Strategic Investment in Chinese Manufacturing

For B2B decision-makers, investing in high-quality mud vibrating screens and steel grating from reputable manufacturers makes undeniable business sense. These components are not mere expenses; they are critical capital investments that directly impact operational efficiency, safety, and long-term profitability. Superior products mean less downtime, reduced maintenance costs, enhanced productivity, and compliance with increasingly strict industry standards.

When considering adopting solutions or partnering with Chinese manufacturers, here are some essential tips:

- Due Diligence is Key: Thoroughly research potential partners. Look for certifications (ISO, CE), robust quality control processes, and a proven track record of supplying to international markets. Companies like Anping County Hangshun often have extensive export experience.

- Prioritize Customization Capabilities: Many Chinese manufacturers, including those specializing in metal grating for sale, offer excellent custom fabrication. Clearly define your specifications and evaluate their capacity to meet unique design requirements and specialized applications.

- Focus on Material Science and Longevity: Enquire about the materials used, their origin, and any specific treatments (e.g., galvanization for carbon steel grating). Durability and resistance to specific environmental factors are crucial for long-term value.

- Evaluate Technical Support and After-Sales Service: A strong partnership goes beyond the initial purchase. Ensure the manufacturer provides adequate technical support, installation guidance, and accessible after-sales service.

- Leverage Digital Communication: Modern Chinese manufacturers are adept at digital communication. Utilize video calls, detailed specifications, and digital mock-ups to streamline the communication and approval process, especially when looking to buy steel grating in bulk.

To future-proof your strategies, consider manufacturers who are actively investing in R&D for sustainable materials, smart manufacturing integration, and solutions that can adapt to changing regulatory landscapes. Partnering with forward-thinking suppliers ensures your operations remain competitive and resilient in a dynamic industrial environment.

Conclusion: FILTECH – A Gateway to Global Excellence

FILTECH continues to be an indispensable event, shaping the global market for industrial filtration and robust material solutions like mud vibrating screens and steel grating. It provides an essential platform for discovering cutting-edge technologies, understanding market trends, and forging strategic partnerships with leading manufacturers from across the globe, including the increasingly influential Chinese contingent.

The emphasis on high-performance materials, custom engineering, and sustainable practices underscores a future where industrial components are not just functional but intelligent, durable, and environmentally conscious. Manufacturers like Anping County Hangshun Wire Mesh Manufacture Co., Ltd are at the forefront of this evolution, offering the precision and reliability that modern industries demand.

To explore advanced steel grating solutions, including various types of steel grating and options for carbon steel grating, and to discuss your specific project needs with a leading expert in wire mesh and grating products, we invite you to learn more. Visit https://www.hfpetromesh.com/swage-locked-steel-grating.html today and discover how their innovative solutions can enhance your industrial operations. Whether you're looking for metal grating for sale or custom-fabricated wire mesh, their expertise ensures you're investing in quality and performance that lasts.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025