- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Durable Steel Walkway Grating & Metal Grates for Safety

Understanding Steel Walkway Grating: An Essential Guide for B2B Professionals

In industrial and commercial environments, the demand for robust, safe, and durable flooring solutions is paramount. Among the leading options, steel walkway grating stands out as a superior choice, offering unparalleled strength, ventilation, and slip resistance. This comprehensive guide delves into the intricacies of these essential structural components, providing B2B decision-makers and engineers with the technical insights needed to make informed procurement decisions. We will explore industry trends, technical specifications, application scenarios, manufacturing processes, and the critical advantages that make steel grating an indispensable asset in various sectors.

Our focus is on delivering an authoritative and trustworthy perspective, ensuring compliance with Google's standards by detailing expertise, illustrating experience, establishing authoritativeness through industry standards and certifications, and building trustworthiness with transparent operational details.

Current Industry Trends and Market Outlook for Steel Walkway Grating

The global market for industrial gratings, particularly steel walkway grating, is experiencing steady growth, driven by expansion in infrastructure projects, industrial manufacturing, and energy sectors. Key trends include an increasing emphasis on safety standards, the adoption of advanced corrosion-resistant coatings, and the demand for lightweight yet high-strength solutions. Digitalization in design and manufacturing, including the use of Building Information Modeling (BIM) and Computer-Aided Design (CAD), is optimizing production processes and enabling more complex, customized designs. Furthermore, sustainability concerns are leading to greater interest in recycled content and energy-efficient manufacturing processes. The market is also seeing a rise in specialized applications requiring specific material grades, such as stainless steel for corrosive environments or galvanized steel for outdoor industrial settings.

Modern industrial applications of steel walkway grating.

The demand for metal walkways gratings is also influenced by stringent regulatory requirements, particularly in sectors like oil and gas, chemical processing, and power generation, where robust and non-slip surfaces are critical for worker safety and operational efficiency. Predictive analytics and IoT integration are slowly making their way into facility management, enabling better maintenance scheduling for grating systems, thus extending their service life and ensuring continuous compliance.

Manufacturing Process Flow of Steel Walkway Grating

The production of high-quality steel walkway grating is a sophisticated process involving several critical stages to ensure structural integrity, durability, and compliance with international standards. The primary materials typically include low carbon steel (e.g., ASTM A36, A1011 SS Grade 36, or equivalent), stainless steel (e.g., 304, 316 for enhanced corrosion resistance), and aluminum alloys for lighter weight requirements.

Key Manufacturing Steps:

- Material Selection & Preparation: Selection of high-grade steel plates and bars. These raw materials undergo initial quality checks for chemical composition and mechanical properties, ensuring they meet specified standards like ASTM A36 or ASTM A569.

- Cutting and Shearing: Bearing bars are precisely cut to the required lengths using hydraulic shears or plasma cutters. Cross bars are also cut to size, often with notches to facilitate interlocking.

- Notching and Punching: For press-locked gratings, slots are precisely notched into the bearing bars, and for swage-locked, cross bars are swaged. For welded gratings, no notching is required for the bearing bars, as cross bars are resistance welded. CNC machining ensures high precision for these cuts.

-

Assembly and Welding/Locking:

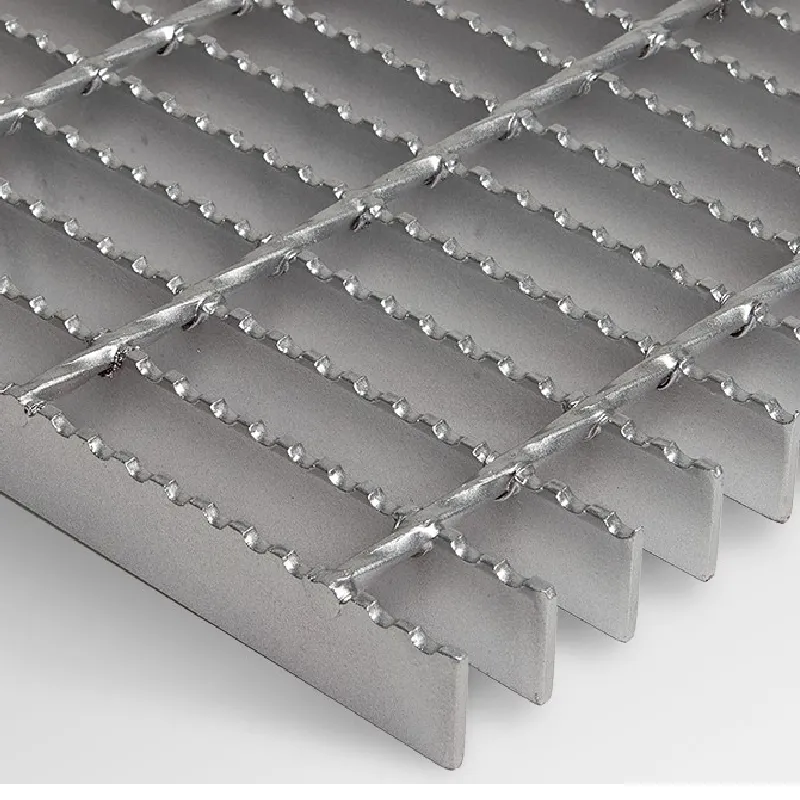

- Welded Grating: Bearing bars and cross bars are joined through a high-pressure resistance welding process, fusing the metals at their intersections. This process, often automated, ensures a strong and durable joint.

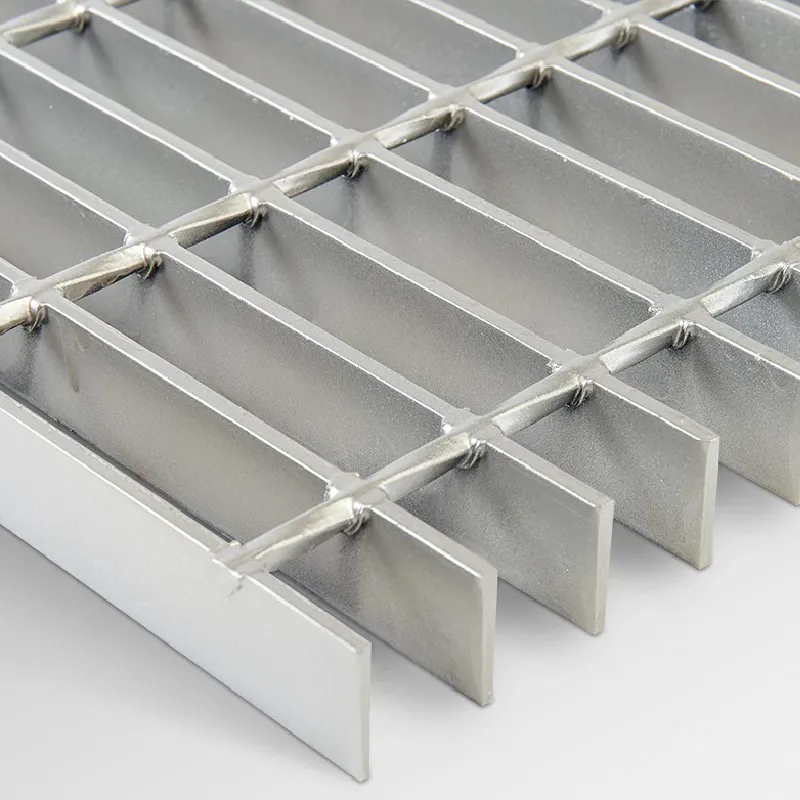

- Press-Locked Grating: Cross bars are hydraulically pressed into pre-cut slots in the bearing bars, creating a secure, interlocked connection without welding.

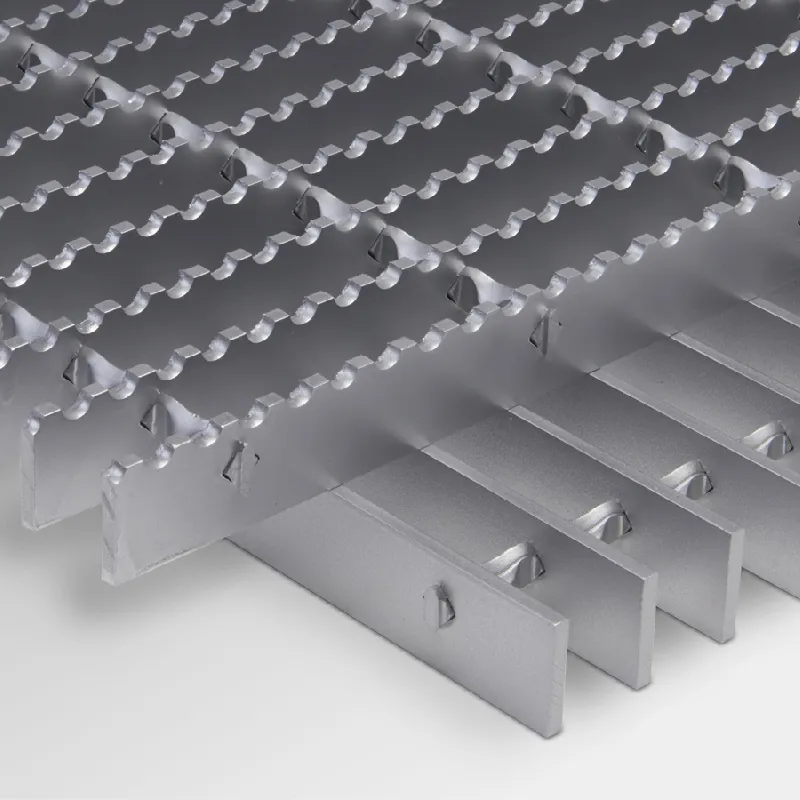

- Swage-Locked Grating: Pre-notched bearing bars are fitted with round cross bars which are then cold-swaged (deformed) into place under high pressure.

- Edging and Banding: The grating panels are often banded on the edges with flat bars, welded to the ends of the bearing bars. This enhances load distribution, rigidity, and overall aesthetic appeal.

-

Surface Treatment:

- Hot-Dip Galvanization: Most common treatment. The fabricated grating is immersed in molten zinc, creating a metallurgical bond that provides exceptional corrosion resistance. Adheres to standards like ASTM A123.

- Painting/Powder Coating: Applied for specific aesthetic requirements or additional environmental protection.

- Pickling and Passivation: For stainless steel gratings, this process removes surface contaminants and restores the passive chromium oxide layer, maximizing corrosion resistance.

- Final Inspection & Quality Control: Each panel undergoes rigorous inspection, including visual checks for welding integrity, dimensional accuracy, flatness, and coating thickness. Testing standards typically conform to ISO 9001 quality management systems, ANSI/NAAMM MBG 531 for metal bar grating, and relevant ASTM standards for material properties and galvanization.

Precision welding in the manufacturing of steel walkway grating.

This meticulous process ensures that the finished steel walkway mesh product boasts a service life often exceeding 20-30 years in standard environments, even longer with proper maintenance and suitable surface treatments, offering significant long-term value for target industries such as petrochemical, metallurgy, power generation, water supply & drainage, shipbuilding, and construction.

Technical Specifications and Parameters

The performance of walkway grates is defined by a set of critical technical specifications, which are crucial for engineers and procurement specialists to consider. These parameters ensure the grating meets structural load requirements, environmental resistance, and safety standards.

Typical Steel Walkway Grating Specifications:

| Parameter | Description | Common Range/Value | Standard |

|---|---|---|---|

| Material Grade | Low Carbon Steel, Stainless Steel (304, 316), Aluminum | ASTM A36, A1011, 304/316 SS | ASTM |

| Bearing Bar Depth | Height of the load-carrying bars | 20mm to 100mm (0.75" to 4") | NAAMM MBG 531 |

| Bearing Bar Thickness | Width of the load-carrying bars | 3mm to 10mm (1/8" to 3/8") | NAAMM MBG 531 |

| Bearing Bar Spacing | Center-to-center distance between bearing bars | 30mm, 40mm, 60mm (1-3/16", 1-1/2", 2-3/8") | NAAMM MBG 531 |

| Cross Bar Spacing | Center-to-center distance between cross bars | 50mm, 100mm (2", 4") | NAAMM MBG 531 |

| Surface Treatment | Protection against corrosion | Hot-dip Galvanized, Painted, Self-color | ASTM A123 |

| Load Capacity | Maximum distributed/concentrated load | Varies by bar size & spacing (e.g., 20kPa to 150kPa) | AASHTO H-20, EN ISO 14122-2 |

| Grating Type | Method of bar interconnection | Welded, Press-Locked, Swage-Locked | Manufacturer Specific |

These parameters collectively determine the suitability of a steel walkway grating for specific applications, influencing factors such as structural integrity, pedestrian comfort, and vehicle load-bearing capacity. Engineers frequently utilize load tables and deflection charts provided by manufacturers, which are developed in accordance with international standards, to specify the correct grating for their project requirements.

Application Scenarios and Technical Advantages

Steel walkway grating is highly versatile and finds extensive use across a multitude of industries, primarily due to its combination of strength, open area, and durability.

Typical Application Scenarios:

- Industrial Platforms and Catwalks: Essential in power plants, chemical factories, and manufacturing facilities for access to machinery and elevated work areas. The open design allows for light, air, and heat penetration, optimizing energy efficiency and safety.

- Stair Treads: Providing anti-slip properties and excellent load-bearing capabilities for industrial staircases, especially in outdoor or wet environments.

- Trench Covers and Drainage Systems: Used in municipal works, water treatment plants, and factories to cover trenches while allowing efficient drainage and preventing debris accumulation. Corrosion resistance is paramount here.

- Bridge Decking: For pedestrian bridges and light-duty vehicular bridges, offering a lightweight yet strong surface with good traction.

- Marine and Offshore Structures: In shipbuilding and offshore platforms, where metal walkways gratings are exposed to harsh saline environments, demanding superior corrosion resistance (often achieved with hot-dip galvanization or stainless steel).

- Storage Facilities and Racking: As durable shelving or flooring in warehouses, offering excellent load distribution and fire suppression system penetration.

Steel walkway grating deployed in an industrial facility for elevated access.

Technical Advantages:

- High Strength-to-Weight Ratio: Steel gratings provide exceptional load-bearing capacity while maintaining a relatively low weight, reducing structural load on supporting elements.

- Excellent Ventilation and Light Penetration: The open mesh design allows for free flow of air, heat, and light, contributing to better energy efficiency (e.g., natural lighting, reduced HVAC load) and a safer environment by preventing heat build-up and ensuring visibility.

- Superior Corrosion Resistance: Hot-dip galvanization (ASTM A123 standard) provides a sacrificial zinc coating that protects the steel from rust and extends service life, particularly in harsh outdoor or corrosive industrial atmospheres. Stainless steel options offer even greater resistance for specialized applications.

- Slip Resistance: Plain or serrated bearing bars provide effective anti-slip surfaces, enhancing safety in areas prone to wetness, oil, or ice, thereby reducing workplace accidents.

- Easy Maintenance: The open structure prevents the accumulation of dirt, debris, and liquids, making cleaning simple and reducing maintenance costs.

- Durability and Long Service Life: Designed to withstand heavy loads, constant traffic, and environmental exposure, leading to a long operational lifespan and reduced replacement frequency.

Vendor Comparison and Selection Criteria

Choosing the right supplier for steel walkway grating is a critical decision that impacts project timelines, budget, and long-term performance. A thorough vendor comparison should extend beyond just price, focusing on factors that ensure quality, reliability, and support.

Key Vendor Comparison Parameters:

| Criterion | Vendor A (Example) | Vendor B (Example) | Importance Score (1-5) |

|---|---|---|---|

| Certifications (ISO, ASTM, etc.) | ISO 9001, ASTM A123 | ISO 9001, EN 1090 | 5 |

| Manufacturing Capabilities | Welded, Press-locked, CNC cutting | Welded, Swage-locked, Custom Fabrication | 4 |

| Customization Options | Material, size, shape, surface | Material, size, loading, specific coatings | 4 |

| Lead Time & Delivery Reliability | Avg. 3-4 weeks, 95% on-time | Avg. 4-5 weeks, 90% on-time | 4 |

| Pricing Competitiveness | Competitive mid-range | Slightly higher, premium quality | 3 |

| Technical Support & Design Aid | CAD services, load calculation | Full engineering support, site visits | 5 |

| Warranty & After-Sales | 5-year structural warranty | 10-year structural warranty, quick issue resolution | 5 |

It is imperative for buyers to evaluate a vendor's experience, particularly their track record with similar projects or within the target industry. A supplier with robust quality control processes, demonstrated by ISO 9001 certification and adherence to standards like ASTM for material and galvanization, offers greater assurance of product integrity and longevity. Strong technical support, including CAD services and load calculation assistance, can significantly streamline project execution.

Customized Solutions for Specialized Needs

While standard steel walkway grating offers broad applicability, many industrial projects require tailored solutions to meet unique operational, structural, or environmental demands. Leading manufacturers excel in providing customization options that ensure optimal fit, performance, and compliance.

Areas of Customization:

- Material Selection: Beyond standard carbon steel, options include specific stainless steel grades (e.g., 304, 316, 316L) for extreme corrosion resistance, or aluminum for lightweight, non-magnetic, and non-sparking applications.

- Bearing Bar and Cross Bar Configurations: Custom dimensions (depth, thickness) and spacing to achieve precise load-bearing capacities, deflection limits, and open area percentages. This is crucial for matching specific structural engineering requirements.

- Surface Profiles: Options for serrated bearing bars to enhance slip resistance in oily, wet, or icy conditions, or plain surfaces where aesthetics are prioritized.

- Panel Shapes and Sizes: Fabrication of irregular shapes (e.g., curved panels, cut-outs for pipes or equipment), and specialized panel sizes to minimize on-site cutting and waste, optimizing installation efficiency.

- Finishes and Coatings: In addition to hot-dip galvanization, custom paint colors (epoxy, polyurethane) for aesthetic matching or additional chemical resistance, and specialized anti-static coatings.

- Accessories: Integration of toe plates, nosing for stair treads, hinged panels for access, and specialized clamping systems.

The ability to provide highly customized steel walkway mesh solutions, backed by experienced engineering teams and advanced fabrication capabilities, distinguishes a premier vendor. This ensures that even the most complex project requirements can be met with precision and adherence to international safety and quality standards.

Application Case Studies

Real-world applications demonstrate the practical advantages and reliability of steel walkway grating in challenging industrial environments. Our company has served numerous clients across various demanding sectors for over two decades, delivering robust and compliant grating solutions.

Case Study 1: Offshore Oil Platform Decking

- Challenge: A leading energy company required durable, corrosion-resistant decking for an offshore oil platform, capable of withstanding extreme marine environments, heavy foot traffic, and equipment loads. The solution also needed to provide excellent drainage and slip resistance for worker safety.

- Solution: We supplied customized metal walkways gratings fabricated from marine-grade stainless steel (316L) with serrated bearing bars. The panels were designed to specific dimensions and load capacities, and included specialized banding for secure installation.

- Outcome: The grating provided a safe, non-slip walking surface that resisted saltwater corrosion and extreme weather. The open design allowed for efficient drainage of seawater and optimized ventilation around critical equipment, contributing to the platform's overall operational safety and longevity. Customer feedback highlighted improved worker confidence and reduced maintenance requirements.

Case Study 2: Wastewater Treatment Plant Walkways

- Challenge: A municipal wastewater treatment facility needed grating for elevated walkways and access platforms. The environment presented significant challenges due to constant moisture, chemical exposure, and the need for hygiene and easy cleaning.

- Solution: Hot-dip galvanized steel walkway grating with a 40mm x 40mm mesh opening was provided. This configuration ensured excellent load-bearing capabilities and allowed easy wash-through of water and sludge, preventing accumulation. Specialized trench covers were also fabricated to match.

- Outcome: The galvanized grating delivered superior corrosion resistance against the aggressive chemicals and moisture prevalent in the plant. The design facilitated easy cleaning, maintaining hygienic conditions, and the robust construction provided a long-lasting, safe walking surface for plant personnel. The solution significantly reduced the plant's long-term maintenance burden and enhanced operational safety.

Robust steel walkway grating providing safe access in an industrial setting.

Trustworthiness and Support: FAQ, Lead Time, Warranty, and Customer Service

Establishing trustworthiness is paramount in B2B transactions. We provide clear commitments regarding product quality, delivery, and post-sales support.

Frequently Asked Questions (FAQ):

-

Q: What is the typical lead time for custom steel walkway grating orders?

A: Standard orders typically have a lead time of 3-4 weeks from design approval to dispatch. Custom or large-volume orders may require 5-7 weeks. Expedited options are available upon request.

-

Q: What are the primary differences between welded and press-locked grating?

A: Welded walkway grates are manufactured by resistance welding cross bars to bearing bars, offering high strength and rigidity. Press-locked grating involves hydraulically pressing cross bars into bearing bar notches, resulting in a cleaner aesthetic with slightly less direct load transfer but excellent lateral stability.

-

Q: How do you ensure the corrosion resistance of your steel grating products?

A: Our primary method is hot-dip galvanization, strictly conforming to ASTM A123 standards, which provides a durable, sacrificial zinc coating. For highly corrosive environments, we offer stainless steel (304, 316) options with pickling and passivation treatments.

-

Q: Can you provide engineering calculations for load capacities and deflections?

A: Yes, our engineering team provides comprehensive load tables and deflection calculations based on industry standards (e.g., NAAMM MBG 531, AASHTO) to ensure the specified grating meets your project's structural requirements.

Lead Time and Fulfillment:

We operate with efficient production schedules and robust logistics to ensure timely delivery. Our standard manufacturing lead time for most steel walkway grating orders is 3-4 weeks. For large-scale projects or complex custom designs, lead times are confirmed at the quotation stage, with clear communication throughout the production cycle. We leverage a network of trusted freight partners to ensure secure and on-time global delivery.

Warranty Commitments:

We stand behind the quality of our steel walkway grating products. All gratings come with a comprehensive 5-year structural warranty, covering defects in materials and workmanship under normal use conditions. Our hot-dip galvanized products are warranted against red rust for 10 years, reflecting our confidence in the longevity and protective qualities of our surface treatments. Specific warranty details are provided with each order.

Customer Support and After-Sales Service:

Our commitment extends beyond delivery. We offer dedicated customer support through experienced technical representatives who can assist with installation guidance, maintenance advice, and troubleshooting. Our after-sales service team is readily available to address any concerns, ensuring a smooth and satisfactory product lifecycle. We prioritize rapid response times and effective resolution of any issues that may arise, fostering long-term partnerships with our clients.

Conclusion

Steel walkway grating remains an indispensable component in modern industrial and architectural infrastructure, valued for its inherent strength, safety features, and adaptability. From the meticulous manufacturing processes adhering to stringent international standards like ISO and ASTM, to its widespread application in diverse and demanding environments, the advantages of high-quality steel walkway grating are clear. By understanding the technical specifications, leveraging customization options, and partnering with authoritative manufacturers, B2B professionals can ensure the selection of grating solutions that deliver optimal performance, longevity, and return on investment for their projects.

References:

- National Association of Architectural Metal Manufacturers (NAAMM). (2009). Metal Bar Grating Manual (MBG 531-09). NAAMM.

- ASTM International. (2017). ASTM A123/A123M - 17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems – Requirements. ISO.

- American Association of State Highway and Transportation Officials (AASHTO). (2017). AASHTO LRFD Bridge Design Specifications (8th Ed.). AASHTO.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025