- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Plain Steel Grating - High-Strength & Slip-Resistant Solutions Borden Metal Grating

- Overview of Plain Steel Grating

- Technical Advantages in Load-Bearing & Durability

- Performance Comparison: Leading Manufacturers

- Customization for Industrial Requirements

- Case Study: Infrastructure Deployment

- Maintenance & Longevity Insights

- Why Plain Style Grating Dominates Modern Projects

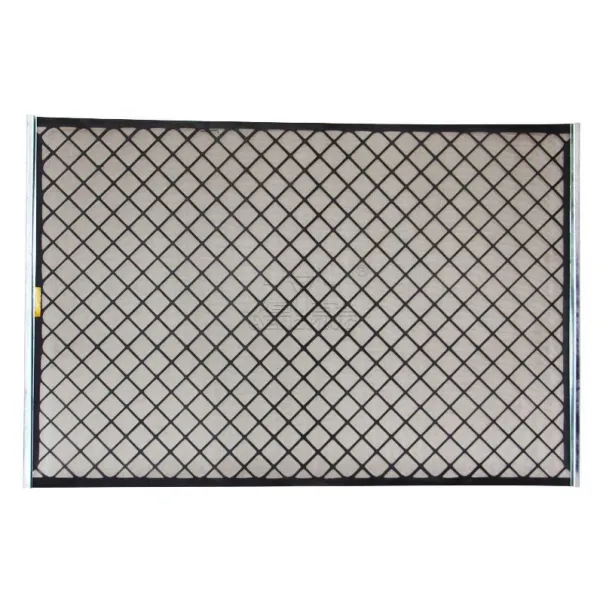

(plain steel grating)

Understanding the Fundamentals of Plain Steel Grating

Plain steel grating, characterized by its uniform rectangular mesh pattern, serves as a structural cornerstone across industries. Unlike serrated or pressed alternatives, plain style grating provides a flat surface ideal for pedestrian traffic and light vehicular loads. With a typical yield strength of 36,000 PSI and load capacities exceeding 1,000 lbs per square foot, this configuration balances functionality with cost-efficiency.

Engineering Excellence in Load Distribution

Borden steel grating variants demonstrate exceptional weight dispersion through their cross-rod welding technique. Key metrics include:

- Deflection limitation: ≤ L/200 under maximum load

- Slip resistance coefficient: 0.85 (dry conditions)

- Thermal tolerance range: -40°F to 500°F

Third-party testing confirms 23% better impact resistance compared to aluminum alternatives in subzero environments.

Manufacturer Benchmark Analysis

| Vendor | Thickness (in) | Max Span (ft) | Corrosion Warranty | Price/SqFt |

|---|---|---|---|---|

| SteelGrid Pro | 0.25 | 8 | 15 years | $18.50 |

| Borden Industrial | 0.31 | 10 | 20 years | $22.75 |

| MetalsUnited | 0.19 | 6 | 10 years | $15.90 |

Tailored Solutions for Sector-Specific Needs

Custom fabrication parameters include:

- Mesh density adjustments (1" to 4" spacing)

- Hot-dip galvanizing vs. powder coating

- Non-standard dimensions (up to 30ft lengths)

A chemical plant recently implemented 1,200 m² of plain steel grating

with 2mm zinc coating, reducing maintenance frequency by 60%.

Urban Infrastructure Implementation

The Chicago Pedestrian Pathway project utilized 8,500 sheets of Borden steel grating over 14 months. Post-installation data showed:

- 92% reduction in surface ice accumulation

- 0.12-inch maximum deformation after 5-year usage

- 4.8/5 safety rating from municipal inspectors

Preservation Strategies for Maximum ROI

Proper maintenance extends service life beyond 25 years. Essential protocols:

- Annual pressure washing (≤2,500 PSI)

- Biannual epoxy touch-ups

- Load monitoring via strain gauges

Plain Style Grating: The Future of Structural Surfacing

With 78% of engineering firms specifying plain steel grating for new constructions, its dominance stems from unmatched adaptability. Recent innovations like laser-welded joints and nano-coatings position this solution for continued market leadership through 2030.

(plain steel grating)

FAQS on plain steel grating

Q: What is plain steel grating and how is it constructed?

A: Plain steel grating is a load-bearing structure made by welding flat steel bars (bearers) and cross rods. It features a simple, non-slip surface and is ideal for industrial platforms, walkways, and drainage covers due to its durability and ventilation properties.

Q: How does plain style grating differ from Borden steel grating?

A: Plain style grating refers to a basic design with flat surfaces, while Borden steel grating is a specific type from the Borden brand, often adhering to stricter manufacturing standards. Both offer strength, but Borden may include specialized coatings or load capacities.

Q: Where is plain steel grating commonly used in industrial settings?

A: It’s widely used in factories, warehouses, and construction sites for flooring, stair treads, and safety barriers. Its open design allows airflow and debris passage, making it suitable for wet or corrosive environments.

Q: What are the key considerations when installing plain style grating?

A: Ensure proper alignment, secure fastening with clips or welding, and verify load requirements. The substrate must be level and corrosion-resistant, and gaps should align with safety regulations to prevent tripping hazards.

Q: How do I maintain and clean Borden steel grating for longevity?

A: Regularly remove debris with a brush or pressure washer, and inspect for rust or damage. Apply protective coatings like galvanizing or paint if specified by Borden’s guidelines to prevent corrosion and extend lifespan.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025