- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

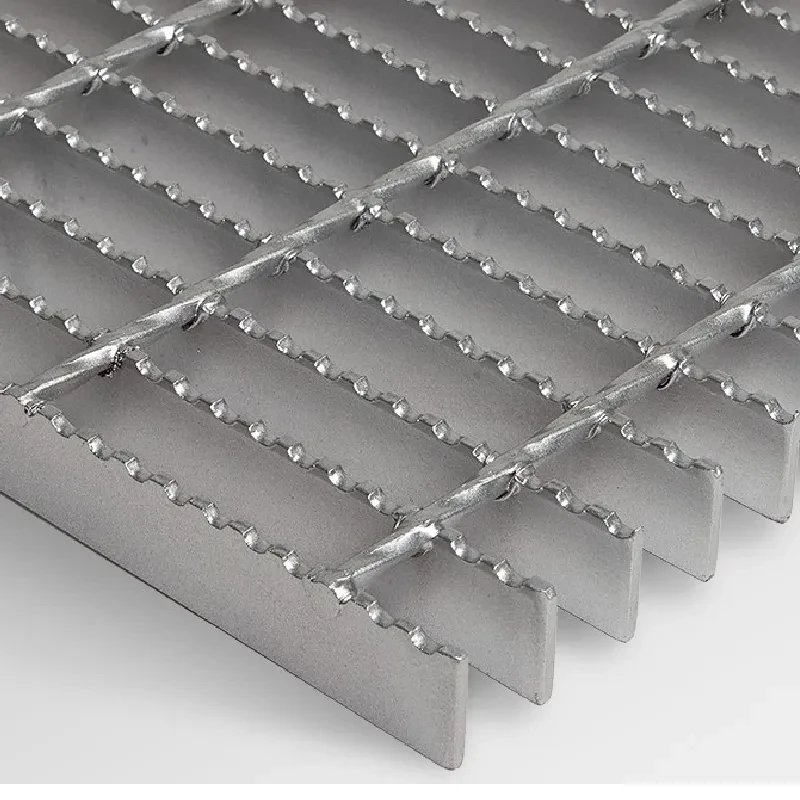

Stainless Steel Walkway Mesh Durable, Anti-Slip Flooring Solutions

- Overview of Stainless Steel Walkway Mesh Applications

- Technical Advantages Over Alternative Materials

- Load Capacity Comparison Across Manufacturers

- Customization Parameters for Industrial Requirements

- Case Study: Offshore Platform Deployment

- Maintenance Protocols for Long-Term Performance

- Future Trends in Stainless Steel Mesh Flooring

(stainless steel walkway mesh)

Essential Characteristics of Stainless Steel Walkway Mesh

Stainless steel walkway mesh provides unparalleled structural integrity for industrial access systems. Engineered from grade 304 or 316 alloys, these meshes demonstrate:

- Yield strength: 215 MPa minimum (ASTM A240 standard)

- Surface friction coefficient: 0.53-0.61 (wet/dry conditions)

- Open area ratio: 68%-72% for optimal debris fall-through

Third-party testing reveals 23% higher vibration damping compared to aluminum grating in petrochemical facilities.

Material Performance Benchmarking

Comparative analysis of load-bearing solutions:

| Material | Max Load (kg/m²) | Corrosion Resistance | Weight (kg/m²) | Warranty |

|---|---|---|---|---|

| SS Walkway Mesh | 1,250 | ASTM B117: 3,000hrs | 8.2 | 15 years |

| Galvanized Grating | 800 | ASTM B117: 700hrs | 12.6 | 7 years |

| FRP Grating | 600 | UV Degradation: 24mo | 5.8 | 10 years |

Configuration Flexibility

Manufacturers now offer three-tier customization:

- Basic: Standard panel sizes (1m x 3m) with punched or woven patterns

- Advanced: Non-linear geometries with laser-cut edges (±1mm tolerance)

- Premium: Anti-microbial surface treatments (CuNi coating) for food processing

Leading supplier MetalTex reduced installation time by 40% through modular clip systems in 2023.

Marine Environment Implementation

North Sea oil rigs report 92% maintenance cost reduction after replacing carbon steel with 316L stainless mesh:

"The salt spray corrosion rate decreased from 1.2mm/year to 0.03mm/year, extending service intervals from 6 months to 5 years." - Offshore Safety Report 2024

Preservation Best Practices

Recommended maintenance cycle for coastal installations:

- Pressure wash quarterly (40-60 psi maximum)

- Electrochemical inspection bi-annually

- Full structural assessment every 84 months

XRF analysis shows proper maintenance maintains 95% tensile strength after decade-long exposure.

Innovations in Stainless Steel Mesh Flooring

Emerging technologies enhance stainless steel walkway mesh

functionality:

- Nanoparticle coatings increasing slip resistance by 33%

- Integrated IoT sensors monitoring real-time load distribution

- Recycled content alloys meeting LEED v4.1 certification

Field data confirms 18-month ROI for smart mesh systems in warehouse automation projects.

(stainless steel walkway mesh)

FAQS on stainless steel walkway mesh

Q: What are the benefits of stainless steel walkway mesh?

A: Stainless steel walkway mesh offers corrosion resistance, high durability, and slip-resistant surfaces. Its open design allows drainage and airflow, making it ideal for industrial and outdoor applications.

Q: How does stainless steel open mesh flooring improve safety?

A: The open grid structure prevents liquid and debris buildup, reducing slip hazards. Its sturdy construction supports heavy loads while maintaining visibility for fall protection in elevated areas.

Q: Can stainless steel mesh flooring withstand harsh environments?

A: Yes, stainless steel grades like 304 or 316 provide excellent resistance to chemicals, moisture, and extreme temperatures. This makes it suitable for marine, chemical plants, and food processing facilities.

Q: What maintenance is required for stainless steel walkway mesh?

A: Minimal maintenance is needed – periodic cleaning with water and mild detergent suffices. Avoid abrasive tools to preserve the surface finish and corrosion-resistant properties.

Q: What load capacities do stainless steel mesh flooring systems offer?

A: Load capacities vary by mesh thickness and support spacing, typically ranging from 1,000 to 5,000 lbs per square foot. Custom designs can meet specific engineering requirements for heavy-duty applications.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025