- Zòn endistriyèl, Sid Anping Town, Hengshui, Hebei, Lachin.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  angle

angle  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- angle

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

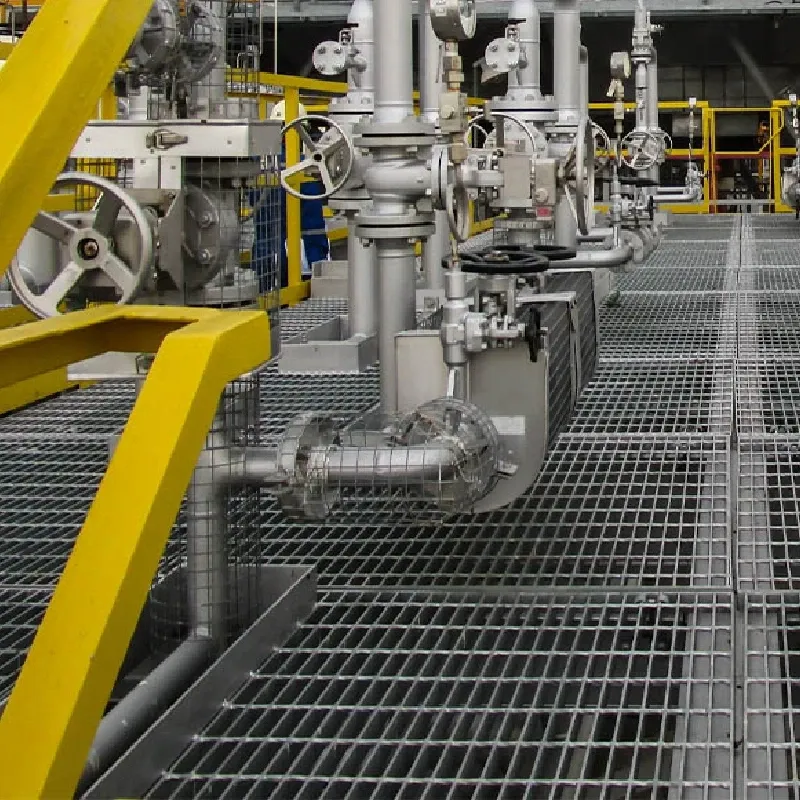

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and Longevity

As a cornerstone of industrial flooring, welded steel bar grating combines superior strength, simplicity, and cost-efficiency into one high-performance platform. Whether installed on factory walkways, maintenance platforms, or drainage trenches, it continues to lead the market for its impressive load-bearing capacity and versatility in heavy-duty settings.

Welded Steel Bar Grating vs. Press-Locked Grating: Load Capacity Matters

One of the most critical comparisons in the world of industrial grating is between welded steel bar grating and press-locked grating. While both have their place, welded bar grating typically surpasses press-locked designs in load-bearing capacity for equivalent sizes and bar spacing.

This strength advantage is due to the process of electrically fusing crossbars to bearing bars under intense pressure and heat. This weld creates a permanent, rigid joint that efficiently transfers loads throughout the grating surface. As a result, welded grating can bear heavier rolling loads—like forklifts or transport carts—without deformation or fatigue, making it the go-to option in manufacturing, shipping, and processing facilities.

Unlike press-locked grating, which is better suited to architectural or pedestrian applications, welded steel bar grating thrives under weight. It is ideal for trenches, pits, and driveways where industrial traffic is constant and reliability is non-negotiable.

How to Select the Right Welded Steel Bar Grating for Your Needs

Choosing the right welded steel bar grating starts with understanding the specific load requirements, environment, and safety standards of your project. Several factors influence selection: bearing bar size, spacing, material grade, finish, and serration.

For high-impact areas or places exposed to vehicular traffic, larger bearing bars (e.g., 1/4" thick) with closer spacing ensure better load distribution and surface integrity. In facilities where slip resistance is crucial—such as food processing plants or oil refineries—serrated welded bar grating offers extra grip and personnel safety.

Material options also play a key role. While standard carbon steel is ideal for most general industrial uses, galvanized or stainless steel versions of welded grating offer better corrosion resistance in outdoor, marine, or chemically aggressive environments.

The open-grid design supports excellent air and light flow, making it suitable for elevated walkways, mezzanine flooring, or ventilation platforms. With a range of custom fabrication options—like toe plates, banding bars, cut-outs, and powder coatings—welded steel bar grating can be tailored to meet project-specific dimensions and aesthetics.

Industry Applications That Rely on Welded Bar Grating Every Day

Welded steel bar grating is indispensable in a wide range of industries where strength and long service life are essential. In the oil and gas sector, it is used on drilling platforms, catwalks, and pipe racks, where both safety and load-bearing strength are paramount. The petrochemical industry favors it for floor grates and elevated service corridors where hazardous spills and heavy equipment traffic are common.

In power generation and utility stations, welded grating is used for transformer platforms, maintenance access decks, and cooling tower bases, offering both drainage and stability. Water treatment plants use welded bar grating over pits and tanks to ensure open flow and corrosion resistance with safe access for workers.

Even in commercial and architectural settings—such as shopping centers, transit hubs, and sports arenas—welded steel bar grating provides an industrial aesthetic while delivering serious structural support.

Enhanced Safety and Easy Maintenance with Welded Steel Bar Grating

Beyond strength, welded steel bar grating is also a champion of workplace safety and long-term maintenance. Its open design prevents water and debris buildup, reducing slip risks and allowing easy cleaning. When fitted with serrated bearing bars, it becomes a slip-resistant surface for wet or oily environments.

The durability of welded grating means fewer replacements and minimal downtime. Galvanized surfaces resist rust, while stainless steel options can endure chemical washdowns and outdoor exposure for years without compromising appearance or strength. These characteristics make welded bar grating an asset to safety compliance and operational efficiency.

Its modular structure also supports quick installation and simple replacement. Whether mounted with saddle clips, weld-on tabs, or bolt-down brackets, the system adapts easily to existing structures without requiring extensive alterations or welding on-site.

Welded Steel Bar Grating FAQs

What makes welded steel bar grating stronger than other types?

Welded steel bar grating is created by welding crossbars to bearing bars, forming a rigid structure that efficiently distributes loads. This process enhances its strength compared to press-locked alternatives.

Where is welded bar grating typically used?

Welded bar grating is widely used in oil and gas facilities, factories, power plants, wastewater treatment plants, and construction sites where heavy loads and harsh conditions demand superior strength and safety.

How do I choose the right welded grating for a project?

Selection depends on load-bearing needs, environmental exposure, and slip-resistance requirements. Key variables include bar size, spacing, finish (galvanized or stainless), and whether serration is needed.

Is welded steel bar grating easy to maintain?

Yes. The open design allows easy drainage and cleaning. Galvanized or stainless welded grating resists corrosion, reducing the need for frequent maintenance or replacement.

Can welded bar grating be customized?

Absolutely. Welded bar grating can be fabricated to custom sizes, shapes, and finishes. Options like toe plates, cut-outs, and edge banding allow adaptation to any industrial or commercial need.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNouvèlAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNouvèlAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNouvèlAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNouvèlAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNouvèlAug.08,2025

-

Maximize Performance with Steel Walkway GratingNouvèlAug.08,2025