- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 20, 2025 11:05

Back to list

serrated steel grating

Serrated aluminum grating has emerged as a cornerstone in the realm of industrial and architectural applications, combining robustness with lightweight properties. As industries and architects continue to innovate, there's an escalating demand for materials that perform efficiently and withstand rigorous environments. Serrated aluminum grating meets these criteria and more, offering distinct advantages that go beyond traditional materials.

Scholarly research and industry reports advocate for the authoritative qualities of serrated aluminum grating. According to studies published in material science journals, aluminum alloys used in grating have a significantly extended life span compared to steel alternatives, especially in environments exposed to frequent moisture. Such findings underscore why industries operating under harsh chemical exposure or coastal climates consistently opt for aluminum grating solutions. Trustworthiness is a core attribute when selecting material for industrial use, and serrated aluminum grating excels in this aspect. Many manufacturers conduct rigorous quality control processes and provide extensive warranties, reassuring clients of the product’s reliability. Testimonials from facility managers who have implemented aluminum grating in their infrastructure often describe a reduction in maintenance requirements and enhanced operational safety, contributing to overall positive long-term asset management. In conclusion, serrated aluminum grating emerges as a prudent choice, both from economic and operational perspectives. Its slip resistance, coupled with unmatched durability and lightweight properties, offers significant advantages. Backed by expert recommendations and verifiable success in challenging environments, the use of serrated aluminum grating is not just a modern trend but a sound investment in safety and performance. For industries venturing into new projects or upgrading existing facilities, relying on this advanced material can significantly contribute to achieving optimal results with long-lasting benefits. Such informed choices foster not only effective resource management but also inspire confidence in the structures built and the safety of those who use them.

Scholarly research and industry reports advocate for the authoritative qualities of serrated aluminum grating. According to studies published in material science journals, aluminum alloys used in grating have a significantly extended life span compared to steel alternatives, especially in environments exposed to frequent moisture. Such findings underscore why industries operating under harsh chemical exposure or coastal climates consistently opt for aluminum grating solutions. Trustworthiness is a core attribute when selecting material for industrial use, and serrated aluminum grating excels in this aspect. Many manufacturers conduct rigorous quality control processes and provide extensive warranties, reassuring clients of the product’s reliability. Testimonials from facility managers who have implemented aluminum grating in their infrastructure often describe a reduction in maintenance requirements and enhanced operational safety, contributing to overall positive long-term asset management. In conclusion, serrated aluminum grating emerges as a prudent choice, both from economic and operational perspectives. Its slip resistance, coupled with unmatched durability and lightweight properties, offers significant advantages. Backed by expert recommendations and verifiable success in challenging environments, the use of serrated aluminum grating is not just a modern trend but a sound investment in safety and performance. For industries venturing into new projects or upgrading existing facilities, relying on this advanced material can significantly contribute to achieving optimal results with long-lasting benefits. Such informed choices foster not only effective resource management but also inspire confidence in the structures built and the safety of those who use them.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

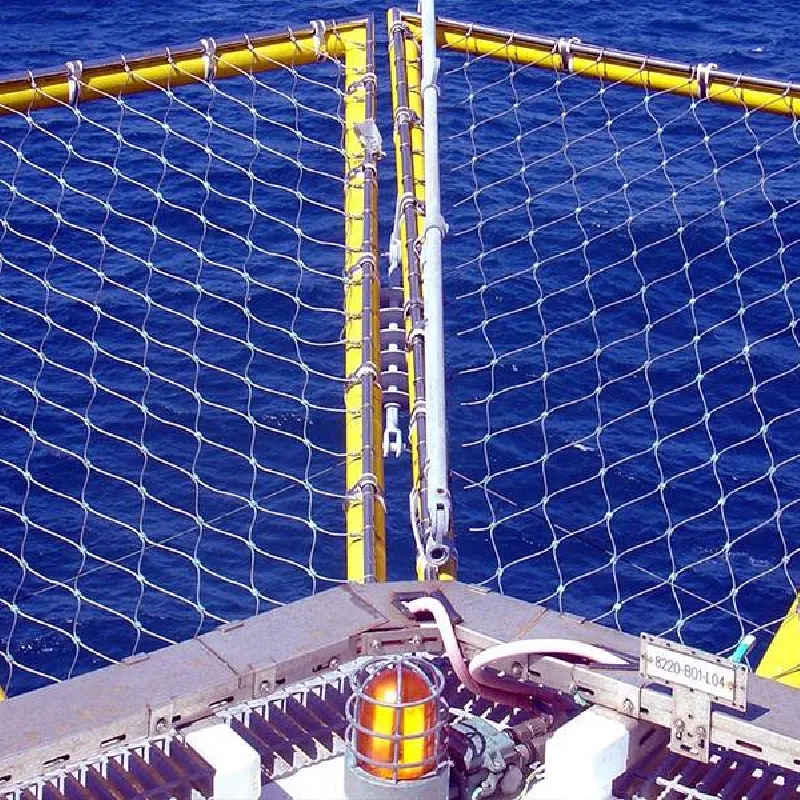

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025