- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 15, 2025 05:17

Back to list

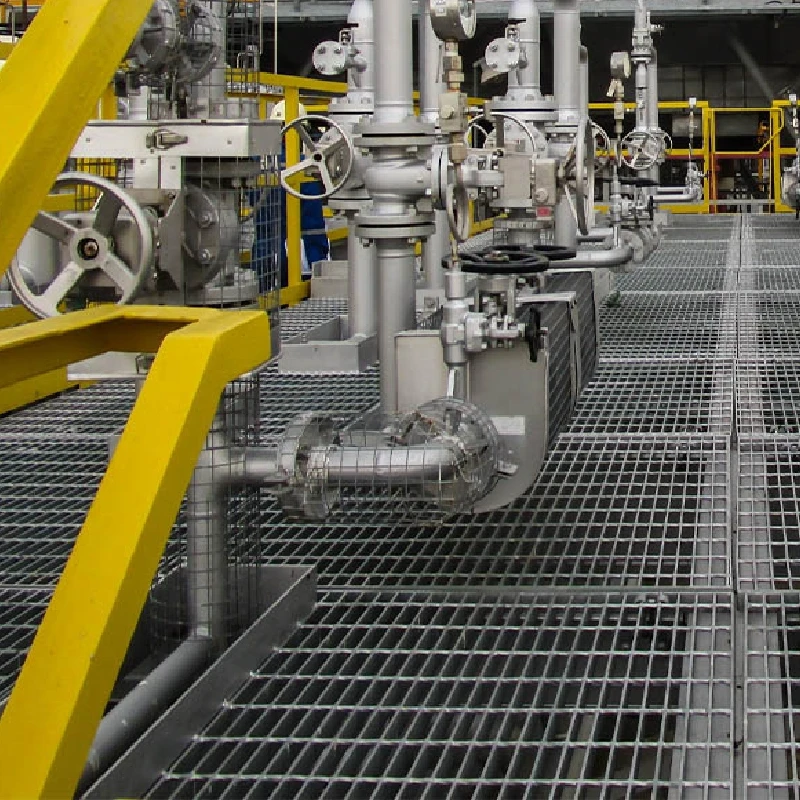

Swage-Locked Steel Grating

Galvanised metal grating has emerged as a critical component in various industrial sectors, ranging from construction to manufacturing. Designers and engineers increasingly rely on this material due to its remarkable durability and cost-effectiveness. The unique galvanisation process enhances the steel grating's natural properties, offering an unparalleled level of protection against corrosion, which is a major concern in industrial applications.

In the realm of trustworthiness, galvanised metal grating distinguishes itself by consistently outperforming alternative materials in independent tests and projects. Its quality and reliability have been validated by countless installations worldwide. Industry standards like ASTM A123/A123M and ISO 1461 ensure that the galvanised coatings are applied correctly, giving additional peace of mind to architects and engineers who specify these materials in their projects. Moreover, galvanised metal grating contributes to sustainability efforts, an increasingly critical factor in modern construction and industrial operations. The galvanisation process is environmentally conscious, producing minimal waste, and the longevity of the metal reduces the frequency of replacements, further conserving resources. Companies looking to enhance their green credentials find galvanised metal grating an appealing option. The authoritative voice of galvanised metal grating is cemented by its ubiquitous application across demanding scenarios. From offshore platforms exposed to salty marine environments to metropolitan building sites facing urban pollution, the resilience of galvanised metal grating is unmatched. Its versatile applications underline the material's standing as an indispensable resource in industrial efficiency and safety. In summary, galvanised metal grating is more than just a component; it is a foundation of industrial infrastructure, backed by years of experience and rigorous testing. As industries continue to evolve, the role of high-quality, reliable materials like galvanised metal grating becomes increasingly indispensable, underscoring its significance in our relentless pursuit of safety and sustainability.

In the realm of trustworthiness, galvanised metal grating distinguishes itself by consistently outperforming alternative materials in independent tests and projects. Its quality and reliability have been validated by countless installations worldwide. Industry standards like ASTM A123/A123M and ISO 1461 ensure that the galvanised coatings are applied correctly, giving additional peace of mind to architects and engineers who specify these materials in their projects. Moreover, galvanised metal grating contributes to sustainability efforts, an increasingly critical factor in modern construction and industrial operations. The galvanisation process is environmentally conscious, producing minimal waste, and the longevity of the metal reduces the frequency of replacements, further conserving resources. Companies looking to enhance their green credentials find galvanised metal grating an appealing option. The authoritative voice of galvanised metal grating is cemented by its ubiquitous application across demanding scenarios. From offshore platforms exposed to salty marine environments to metropolitan building sites facing urban pollution, the resilience of galvanised metal grating is unmatched. Its versatile applications underline the material's standing as an indispensable resource in industrial efficiency and safety. In summary, galvanised metal grating is more than just a component; it is a foundation of industrial infrastructure, backed by years of experience and rigorous testing. As industries continue to evolve, the role of high-quality, reliable materials like galvanised metal grating becomes increasingly indispensable, underscoring its significance in our relentless pursuit of safety and sustainability.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025