- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

galvanised iron grating

The Versatility and Applications of Galvanised Iron Grating

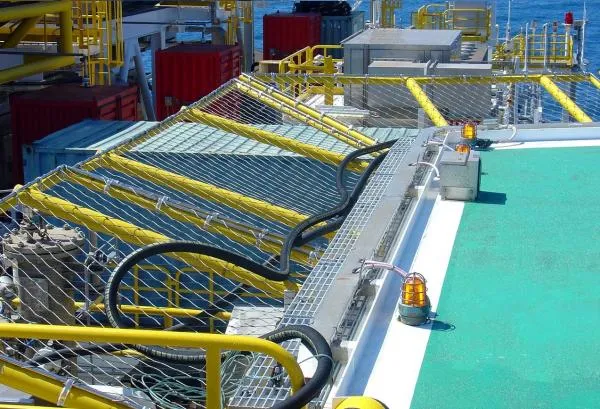

Galvanised iron grating is an essential component in various industrial and architectural applications, renowned for its strength, durability, and resistance to corrosion. The process of galvanization, which entails coating iron or steel with zinc, provides a protective barrier against environmental factors that can lead to rust and deterioration. This characteristic makes galvanised iron grating particularly valuable in settings where exposure to moisture and corrosive elements is common.

One of the most significant advantages of galvanised iron grating is its structural integrity. It is designed to withstand heavy loads and harsh conditions, making it ideal for use in industrial environments such as factories, warehouses, and construction sites. The open design of the grating allows for excellent drainage, reducing the risk of water pooling, which can lead to safety hazards. This feature is especially beneficial in walkways, platforms, and crosswalks where slip resistance is vital.

In addition to its functionality, galvanised iron grating also offers aesthetic benefits

. Many architects and designers appreciate the versatile appearance of this material, which can complement a range of building styles. It can be used for everything from flooring to architectural barriers, providing a modern and industrial look that can enhance the overall design of a structure. The ease of customization further adds to its appeal; grating can be cut and molded into various shapes and sizes to fit specific project requirements.Moreover, galvanised iron grating is lightweight compared to solid metal plates, making it easier to handle and install. This characteristic can lead to reduced labor costs and shorter installation times. In addition, the long lifespan of galvanised iron grating—often exceeding 30 years—means a lower lifetime cost for maintenance and replacement.

galvanised iron grating

The applications of galvanised iron grating are vast and varied. In the commercial sector, it is commonly used in parking garages and pedestrian walkways, providing a sturdy yet safe surface for both vehicles and foot traffic. In wastewater treatment facilities, the grating is used for walkways over tanks and pools, allowing maintenance personnel to safely access essential equipment. Additionally, in the agricultural sector, galvanised iron grating is employed in livestock pens and feedlots, delivering a hygienic and durable surface that can withstand the rigors of daily use.

Safety is another crucial aspect of galvanised iron grating. The anti-slip properties of the material make it an ideal choice for areas prone to wet conditions. Various surface treatments, such as serrations or patterns, can further enhance grip, ensuring the safety of users. This is particularly important in public spaces and industrial areas where slip and fall incidents may pose significant risks.

Environmental considerations are increasingly impacting material choices in construction and industrial applications. Galvanised iron grating is a sustainable option, as it can be recycled at the end of its life cycle, reducing waste and conserving resources. Furthermore, the longevity of the material minimizes the need for frequent replacements, supporting sustainable building practices.

In conclusion, galvanised iron grating is a highly versatile material that finds application across numerous industries. Its strength, durability, corrosion resistance, and aesthetic appeal make it a preferred choice for a variety of projects, from industrial facilities to commercial buildings. As industries continue to prioritize safety and sustainability, the demand for galvanised iron grating is likely to remain strong, ensuring its relevance in the construction and design landscape. Whether used for practical purposes or as a component of innovative architecture, galvanised iron grating stands out as a reliable and effective solution in modern engineering.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025