- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 14, 2025 11:52

Back to list

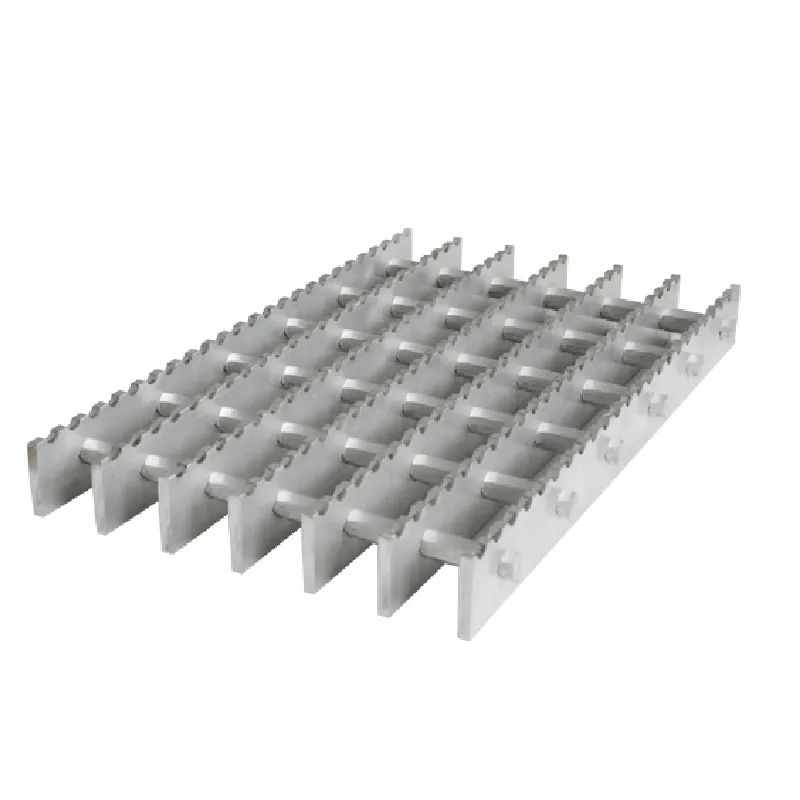

Shale Shaker Screen

In a world driven by technological advancements and efficient operations, industries reliant on solid-liquid separation recognize the indispensable value of utilizing cutting-edge equipment. One such critical component is the shale shaker screen mesh, a pivotal element in various sectors including oil and gas exploration, mining, and waste management. The significance of this product often goes understated, yet its role in improving operational efficiencies and minimizing resource wastage is unparalleled.

Authority in the realm of shale shaker screen mesh emerges from a comprehensive portfolio of research and proven results. Companies that establish themselves as leaders in screen technology invest in continuous research and development, often collaborating with field operators to glean insights into real-world challenges. This cooperation translates into iterative improvements and introductions of innovative products that respond aptly to ever-evolving industrial needs. A company's authority is further solidified by patents and proprietary technologies that demonstrate a commitment to advancing the field and fulfilling specific industry requirements effectively. Trustworthiness, the backbone of any long-term industrial relationship, is substantiated through transparency and reliability in product promises. By delivering products that consistently meet or exceed performance expectations, manufacturers build trust with operators. Testimonials and case studies serve as testaments to a product's reliability, providing potential customers with confidence in the selection process. Moreover, comprehensive after-sales support and warranties further bolster a company's trustworthiness, offering assurance that the company stands behind its products and is prepared to support operators throughout the product's lifecycle. In conclusion, the nuanced understanding and strategic application of shale shaker screen mesh can dramatically enhance operational success in industries dependent on effective solid-liquid separation. By harnessing the collective knowledge gathered through experience, tapping into deep technical expertise, establishing industry authority, and nurturing trustworthiness, companies can ensure that their screen solutions serve as reliable workhorses, optimizing productivity and reducing costs across diverse industrial landscapes.

Authority in the realm of shale shaker screen mesh emerges from a comprehensive portfolio of research and proven results. Companies that establish themselves as leaders in screen technology invest in continuous research and development, often collaborating with field operators to glean insights into real-world challenges. This cooperation translates into iterative improvements and introductions of innovative products that respond aptly to ever-evolving industrial needs. A company's authority is further solidified by patents and proprietary technologies that demonstrate a commitment to advancing the field and fulfilling specific industry requirements effectively. Trustworthiness, the backbone of any long-term industrial relationship, is substantiated through transparency and reliability in product promises. By delivering products that consistently meet or exceed performance expectations, manufacturers build trust with operators. Testimonials and case studies serve as testaments to a product's reliability, providing potential customers with confidence in the selection process. Moreover, comprehensive after-sales support and warranties further bolster a company's trustworthiness, offering assurance that the company stands behind its products and is prepared to support operators throughout the product's lifecycle. In conclusion, the nuanced understanding and strategic application of shale shaker screen mesh can dramatically enhance operational success in industries dependent on effective solid-liquid separation. By harnessing the collective knowledge gathered through experience, tapping into deep technical expertise, establishing industry authority, and nurturing trustworthiness, companies can ensure that their screen solutions serve as reliable workhorses, optimizing productivity and reducing costs across diverse industrial landscapes.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025