- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Fév . 01, 2025 02:37

Back to list

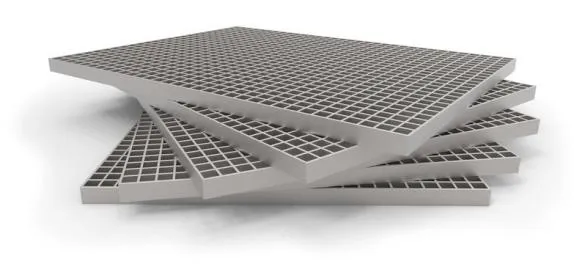

walkway grates

Navigating the intricacies of selecting floor grates metal types involves a deep dive into understanding material specifications, sustainability, and application-specific requirements. Floor grates, essential in both residential and industrial settings, serve vital roles in ensuring safety, functionality, and aesthetic appeal.

Stainless steel grates stand as exemplars of enduring performance and superior resistance, unrivaled in settings demanding stringent hygiene standards such as food processing units and healthcare facilities. The inherent anti-corrosive properties of stainless steel, contributed by chromium content, make these grates a reliable choice for both wet and dry applications. When evaluated for environmental sustainability, stainless steel, being fully recyclable, offers an eco-conscious choice that aligns with green building standards, thus reinforcing trust in its long-term ecological impact. Moreover, bronze grates, though less common, bring a touch of elegance and historical aesthetics, ideal in restoration projects or museum settings. Their resistance to saltwater corrosion also makes them suitable for maritime applications. Employing bronze in grate construction requires expert knowledge in metallurgy and historical material restoration to balance functionality with preserving aesthetic integrity. The installation and maintenance oversee another layer of expertise and trustworthiness. Correct sizing, proper support installation, and compliance with load-bearing requirements guarantee longevity and performance efficacy. Routine maintenance, tailored to the specific metal type, ensures continued functionality and safety compliance, embedding reliability in consumer expectations. In conclusion, mastering the choice of floor grates metal intertwines technical expertise and responsible material choices, catering to robust usage while endorsing environmental mindfulness. When curated with precision and expertise, these metal grates not only fulfill their functional role but also resonate with modern architectural needs, sustainability goals, and safety imperatives, fostering brand authority and consumer trust.

Stainless steel grates stand as exemplars of enduring performance and superior resistance, unrivaled in settings demanding stringent hygiene standards such as food processing units and healthcare facilities. The inherent anti-corrosive properties of stainless steel, contributed by chromium content, make these grates a reliable choice for both wet and dry applications. When evaluated for environmental sustainability, stainless steel, being fully recyclable, offers an eco-conscious choice that aligns with green building standards, thus reinforcing trust in its long-term ecological impact. Moreover, bronze grates, though less common, bring a touch of elegance and historical aesthetics, ideal in restoration projects or museum settings. Their resistance to saltwater corrosion also makes them suitable for maritime applications. Employing bronze in grate construction requires expert knowledge in metallurgy and historical material restoration to balance functionality with preserving aesthetic integrity. The installation and maintenance oversee another layer of expertise and trustworthiness. Correct sizing, proper support installation, and compliance with load-bearing requirements guarantee longevity and performance efficacy. Routine maintenance, tailored to the specific metal type, ensures continued functionality and safety compliance, embedding reliability in consumer expectations. In conclusion, mastering the choice of floor grates metal intertwines technical expertise and responsible material choices, catering to robust usage while endorsing environmental mindfulness. When curated with precision and expertise, these metal grates not only fulfill their functional role but also resonate with modern architectural needs, sustainability goals, and safety imperatives, fostering brand authority and consumer trust.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025