- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 11:43

Back to list

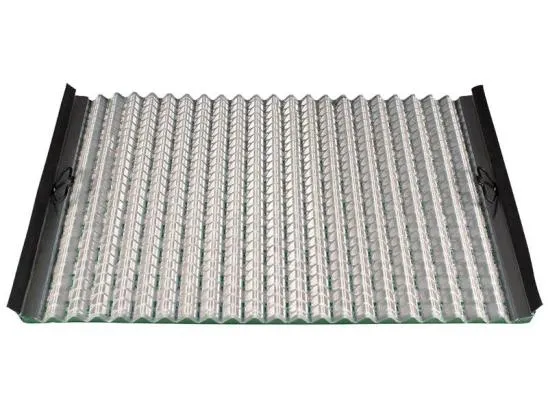

concrete weight coating mesh

When diving into the intricacies of pipeline construction, the importance of concrete weight coating mesh cannot be overstated. This vital component ensures not only the stability of underwater pipelines but also their longevity and resilience against harsh aquatic conditions. As we delve deeper, we uncover the layers of its construction, application, and the value it adds to infrastructure projects worldwide.

In terms of authoritativeness, concrete weight coating mesh is universally recognized by engineering and construction bodies. Organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) endorse its use, integrating specifications into their guidelines. This endorsement reflects years of research and empirical data that support the pivotal role of concrete weight coating mesh in preserving pipeline integrity. The trustworthiness of suppliers and manufacturers of this product is paramount. Companies with a proven track record offer transparency in their operations, often providing detailed documentation on the materials used, manufacturing processes, and quality assurance measures. This transparency builds client confidence, reassuring stakeholders of the product's reliability in critical applications. From an experienced perspective, choosing the right provider for concrete weight coating mesh involves careful consideration of several factors. Assessing the supplier's reputation, the quality of customer feedback, and their adherence to global standards are essential steps. Furthermore, innovative manufacturers offer customization options, tailoring mesh configurations to meet specific project requirements and environmental challenges. In conclusion, concrete weight coating mesh is a cornerstone in modern pipeline engineering. Its blend of weight provision, structural protection, and corrosion resistance represents the culmination of decades of technological advancement and domain expertise. For industries relying on pipeline infrastructure, investing in high-quality concrete weight coating mesh translates into enhanced operational efficiency and sustainability. As technological advancements continue to evolve, so too will the applications and capabilities of this indispensable engineering solution.

In terms of authoritativeness, concrete weight coating mesh is universally recognized by engineering and construction bodies. Organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) endorse its use, integrating specifications into their guidelines. This endorsement reflects years of research and empirical data that support the pivotal role of concrete weight coating mesh in preserving pipeline integrity. The trustworthiness of suppliers and manufacturers of this product is paramount. Companies with a proven track record offer transparency in their operations, often providing detailed documentation on the materials used, manufacturing processes, and quality assurance measures. This transparency builds client confidence, reassuring stakeholders of the product's reliability in critical applications. From an experienced perspective, choosing the right provider for concrete weight coating mesh involves careful consideration of several factors. Assessing the supplier's reputation, the quality of customer feedback, and their adherence to global standards are essential steps. Furthermore, innovative manufacturers offer customization options, tailoring mesh configurations to meet specific project requirements and environmental challenges. In conclusion, concrete weight coating mesh is a cornerstone in modern pipeline engineering. Its blend of weight provision, structural protection, and corrosion resistance represents the culmination of decades of technological advancement and domain expertise. For industries relying on pipeline infrastructure, investing in high-quality concrete weight coating mesh translates into enhanced operational efficiency and sustainability. As technological advancements continue to evolve, so too will the applications and capabilities of this indispensable engineering solution.

Share

Prev:

Latest news

-

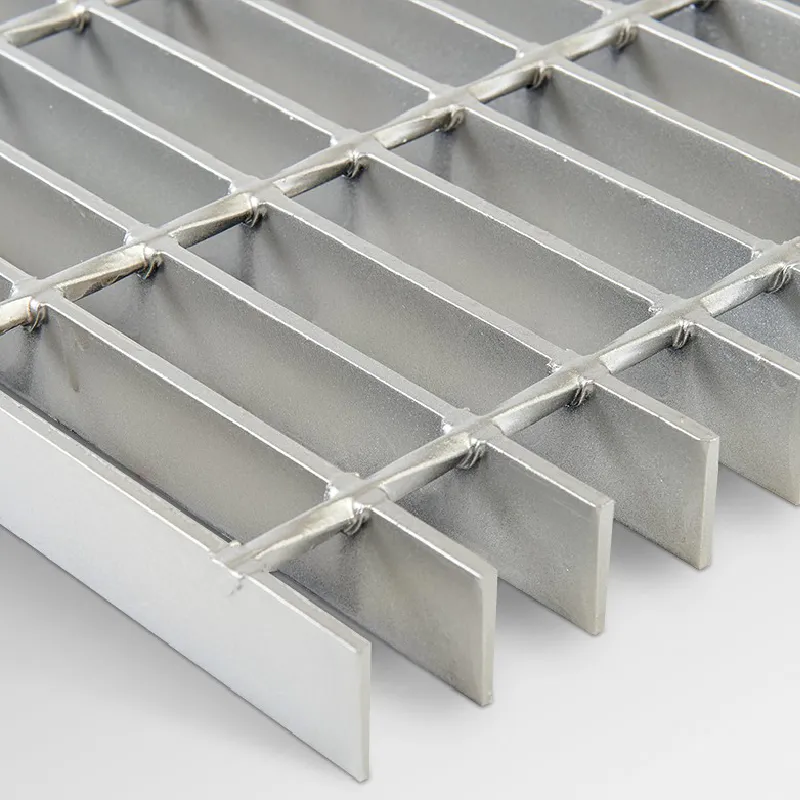

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025