- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Concrete Weight Coating for Pipes to Enhance Stability and Durability in Subsea Applications

Understanding Concrete Weight Coating for Pipes

Concrete weight coating (CWC) is a crucial process in the pipeline industry, especially for underwater applications. This method involves applying a layer of concrete to the outside of pipelines, enhancing their stability, weight, and overall durability. In this article, we will explore the importance of concrete weight coating, its applications, benefits, and the process involved in the coating of pipes.

Importance of Concrete Weight Coating

Pipelines, particularly those laid under water, need immense stability to withstand various pressures and environmental conditions. Concrete weight coating provides the necessary mass to prevent the pipes from floating, particularly in offshore environments. Without sufficient weight, pipelines can become dislodged from their intended paths, leading to potential leaks, costly repairs, and significant environmental harm.

Moreover, CWC serves as a protective layer that shields pipes from external damage. When pipelines are exposed to harsh ocean currents, underwater debris, or extreme temperature variations, the added concrete layer absorbs and dissipates these impacts, ensuring the integrity of the underlying pipe material.

Applications

Concrete weight coating is predominantly used in the oil and gas industry for subsea pipelines. These pipelines transport hydrocarbons across vast distances, often from offshore drilling platforms to onshore facilities. In addition to oil and gas, concrete weight coating is used in water and sewage treatment facilities, where pipes need to remain stable in variable water environments.

Furthermore, CWC is also beneficial in marine construction projects and deep-sea installations. The weight coating allows for easier handling during transportation and installation, making it a preferred choice for contractors and engineers alike.

Benefits of Concrete Weight Coating

concrete weight coating pipe

1. Enhanced Stability The primary advantage of concrete weight coating is the added stability it provides to pipes in various aquatic environments. It ensures that pipelines remain in position, reducing the likelihood of flow disruptions and system failures.

2. Protection Against Corrosion Concrete acts as a barrier against corrosive elements found in water, such as salt and chemicals. This protective aspect prolongs the lifespan of pipelines, reducing maintenance and replacement costs over time.

3. Improved Durability Incorporating concrete into the pipeline system enhances its resistance to harsh weather, underwater conditions, and physical impacts, contributing to a longer operational lifespan.

4. Cost-Effectiveness Although the initial cost of concrete weight coating can be higher than other methods, it often leads to significant savings in the long run due to reduced repair and maintenance expenses and increased pipeline lifespan.

The Coating Process

The process of concrete weight coating typically begins with the preparation of the pipeline surface. The pipes are usually cleaned and inspected to ensure they are free of debris, rust, or imperfections that could affect the adhesion of the concrete. Once prepped, the pipes are then submerged in a specialized coating facility where the concrete is applied using one of several methods, including rotating drums or spraying techniques.

After the concrete is applied, the pipes are cured to ensure that the coating hardens and adheres properly. This curing process can last several days, depending on the thickness of the concrete and environmental conditions. Following curing, the coated pipes undergo final inspections before being transported to their installation sites.

Conclusion

Concrete weight coating is an essential process in the pipeline industry that enhances the stability, protection, and durability of pipes used in various applications. Its importance cannot be overstated, especially in offshore environments where the risks associated with floating or damaged pipelines can lead to catastrophic consequences. As the demand for reliable and efficient pipeline solutions grows, concrete weight coating will continue to play a vital role in ensuring the safety and integrity of critical infrastructure.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

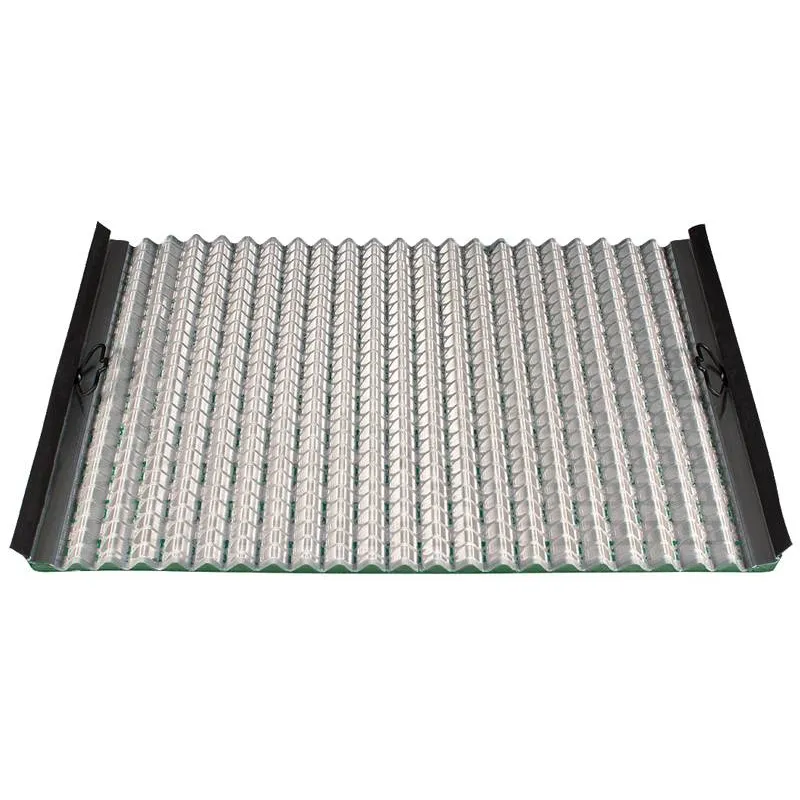

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025