- Industriegebiet, südlich der Stadt Anping, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Englisch

Englisch  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Englisch

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

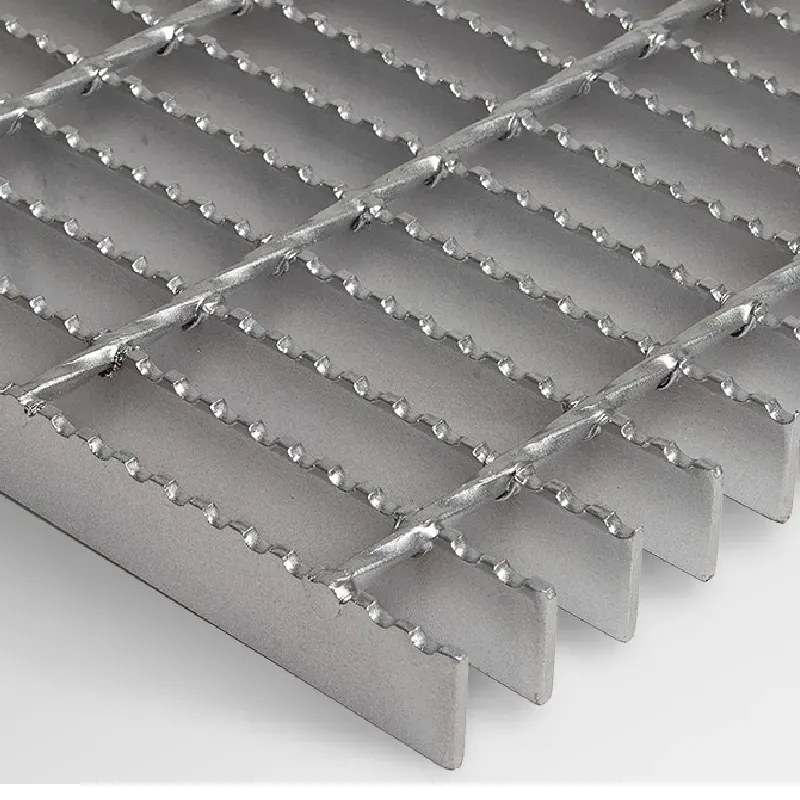

Steel Walkway Grating: Reliable, Resilient, and Built for Every Step

A robust and essential feature of industrial, commercial, and architectural infrastructure, steel walkway grating delivers unparalleled strength, durability, and safety. From maintenance bridges in energy plants to public access platforms, this dependable solution keeps operations running smoothly in all environments.

Surface Treatment Impacts the Lifespan of Steel Walkway Grating

One of the key considerations when choosing steel walkway grating is its surface treatment, which directly affects the product’s lifespan and performance. Plain carbon metal grate walkway surfaces without coatings can last around 10–15 years in non-corrosive environments. However, when galvanized, the zinc coating significantly extends the service life—up to 25–30 years, even in outdoor and semi-corrosive conditions.

For areas exposed to harsh chemicals, salt spray, or constant moisture, stainless steel walkway grating is the superior choice. With excellent resistance to rust, acids, and abrasion, it can last more than 50 years with minimal maintenance. In food processing, marine applications, and chemical manufacturing, stainless steel walkway grating is not only the longest-lasting option but also complies with hygiene and safety standards.

Choosing the right finish—be it mill finish, galvanized, or stainless—will ultimately depend on the environment and load-bearing needs. It is this level of adaptability that keeps steel walkway grating as a top-tier solution across industries.

Cold Climate Performance: Steel Walkway Grating Holds Firm in the Freeze

Cold regions put materials to the test—but steel walkway grating passes with flying colors. Whether in Arctic oil rigs, northern utility plants, or mountain communications towers, this product retains its integrity even at sub-zero temperatures.

Stainless steel walkway grating is particularly effective in cold climates, maintaining ductility and preventing brittleness. Its slip-resistant surface options, including serrated bars, provide reliable footing even in icy or snow-covered conditions. Additionally, the open-grid design prevents snow accumulation and allows efficient drainage, reducing risks of slippage.

For snow belt industries and alpine facilities, the installation of steel walkway grating on walkways, stairs, and elevated platforms ensures year-round accessibility without heavy maintenance. The rugged welds and mechanical strength maintain structural integrity in the face of freezing, thawing, and mechanical load stress.

Steel Walkway Grating Prices and Market Trends Remain Positive

In recent years, demand for steel walkway grating has seen continuous growth, driven by infrastructure upgrades, stricter safety codes, and increased industrialization. Markets across North America, Europe, and Southeast Asia are reporting strong demand in sectors like power generation, water treatment, mining, and public transportation.

As for steel walkway grating prices, the range largely depends on the type of steel used, bar dimensions, spacing, finish, and fabrication complexity. Galvanized grating remains the most economical option, while stainless steel walkway grating commands a premium due to its longevity and corrosion resistance. Current pricing trends indicate a stable market, with modest increases due to steel raw material costs and customization requirements.

Customers investing in long-term infrastructure are increasingly choosing metal grate walkway solutions that meet both performance and aesthetic needs. Decorative grating designs for architectural walkways are also on the rise, combining functionality with sleek industrial styling.

Steel Walkway Grating:From Public Infrastructure to Industrial Use

Few materials can match the versatility of steel walkway grating. In factories and refineries, it is used on elevated maintenance catwalks, inspection decks, and rooftop service paths. The open-grid pattern facilitates light penetration, ventilation, and drainage, while ensuring safe passage for workers and equipment.

Municipalities use metal grate walkway panels in bridge construction, subway stations, and water treatment facilities, where high traffic and environmental exposure are common. In stadiums, exhibition centers, and airports, decorative stainless options add both safety and visual appeal to public walkways.

Because it is easy to fabricate into any size, shape, or configuration, steel walkway grating also fits seamlessly into marine docks, mining platforms, energy grid towers, and rail maintenance yards. Its strength-to-weight ratio and customizable design make it one of the most flexible load-bearing solutions available.

Steel Walkway Grating FAQs

What’s the typical lifespan of steel walkway grating with different coatings?

Plain carbon steel walkway grating can last 10–15 years, while galvanized grating offers 25–30 years of durability. Stainless steel walkway grating can exceed 50 years, making it ideal for corrosive or long-term applications.

Can metal grate walkway systems be used in extremely cold environments?

Yes. Steel walkway grating performs excellently in cold regions. It resists brittleness, allows snow drainage, and provides slip resistance. Stainless steel walkway grating is especially effective for freezing temperatures.

What are the main industries that use steel walkway grating?

Steel walkway grating is used in oil and gas, power generation, chemical plants, public infrastructure, food processing, and mining. It’s also popular in architecture for its structural and visual appeal.

How are steel walkway grating prices determined?

Steel walkway grating prices depend on material type, finish, size, and customization. Galvanized options are cost-effective, while stainless steel walkway grating is priced higher for its premium durability and corrosion resistance.

Why choose metal grate walkway products over concrete or wood platforms?

Metal grate walkway solutions are lighter, stronger, more durable, and easier to maintain than concrete or wood. They offer better slip resistance, ventilation, and drainage, especially in industrial settings.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNachrichtAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNachrichtAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNachrichtAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNachrichtAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNachrichtAug.08,2025

-

Maximize Performance with Steel Walkway GratingNachrichtAug.08,2025