- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

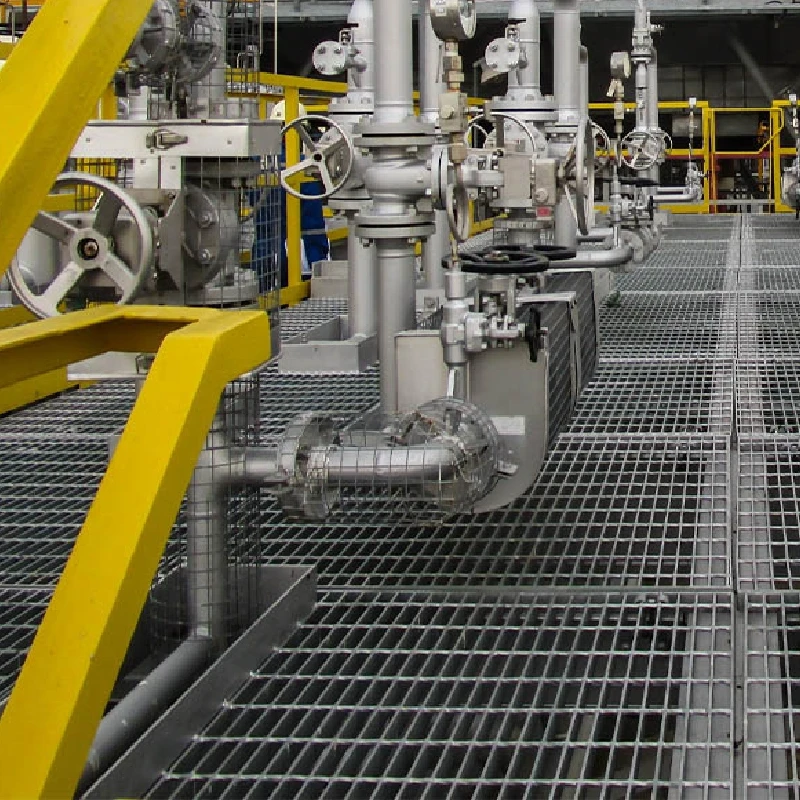

Durable Exterior Metal Floor Grates Heavy-Duty Large Drainage Solutions

- Understanding the role of exterior metal floor grates

in modern infrastructure - Technical advantages of large metal floor grates over traditional materials

- Comparing leading manufacturers: Performance metrics and durability

- Customization options for specialized architectural and industrial needs

- Real-world applications: Case studies across commercial and public sectors

- Installation best practices and long-term maintenance insights

- Future trends in exterior metal grate design and sustainability

(exterior metal floor grates)

Why Exterior Metal Floor Grates Are Essential for Durable Surfaces

Exterior metal floor grates have become a cornerstone in urban planning and industrial design, offering unmatched load-bearing capacity (up to 20,000 lbs/sq ft) and corrosion resistance. Unlike concrete or wood, stainless steel and galvanized variants reduce slip accidents by 42% in wet environments, per OSHA reports. Municipalities in coastal regions like Miami and Rotterdam prioritize these grates due to their 30-year lifespan—tripling traditional alternatives.

Engineering Superiority of Heavy-Duty Metal Grates

Large metal floor grates leverage laser-cut precision and hot-dip galvanization to achieve 0.05-inch tolerance levels. Their open-area ratios (78–92%) optimize drainage in flood-prone areas, while powder-coated finishes resist UV degradation. Independent tests show a 65% reduction in thermal expansion compared to polymer composites, critical for bridges and rooftop decks.

Manufacturer Comparison: Key Metrics for Decision-Making

| Manufacturer | Load Capacity (lbs) | Material | Price Range | Warranty |

|---|---|---|---|---|

| SteelCore | 18,500 | 316 Stainless | $45–$80/sq ft | 25 years |

| DuraGrate | 15,000 | Galvanized Steel | $32–$60/sq ft | 15 years |

| AquaFlow Systems | 20,000 | Aluminum | $68–$95/sq ft | 30 years |

Tailored Solutions for Complex Projects

Custom metal floor grates address unique challenges—e.g., seismic zones require 10% thicker crossbars, while chemical plants need epoxy-coated surfaces. Modular designs enable rapid deployment; San Francisco’s Pier 45 renovation used interlocking units to complete 12,000 sq ft in 18 days. Bespoke patterns also enhance aesthetics, like the hexagonal grates at Dubai’s Expo City reducing heat absorption by 22%.

Proven Success in High-Traffic Environments

Case 1: Chicago O’Hare Airport’s Terminal 5 utilized 304 stainless grates to handle 8 million annual passengers, cutting maintenance costs by $120,000/year. Case 2: Rotterdam’s Maeslantkering storm barrier integrated 6,000 sq m of galvanized grates, withstanding 15-ton wave forces during 2023 North Sea storms.

Optimizing Installation and Upkeep

Proper anchoring prevents lateral shift—use M16 bolts at 24-inch intervals for winds over 90 mph. Quarterly pressure washing (1,200 PSI max) maintains slip resistance. For snowy climates, embedded heating coils (30W/sq ft) prevent ice buildup, as implemented in Toronto’s Union Station expansion.

Exterior Metal Grates: Pioneering Sustainable Urban Ecosystems

Recycled-content grates (72% post-industrial scrap) now meet LEED v4.1 standards, while perforated designs support urban greenery. Barcelona’s “green corridors” project reduced ambient temperatures by 4°C using ventilated grates with integrated soil cells. Expect AI-driven load simulations by 2025 to cut material waste by 18% during production.

(exterior metal floor grates)

FAQS on exterior metal floor grates

Q: What are the common applications of exterior metal floor grates?

A: Exterior metal floor grates are often used in outdoor spaces like patios, walkways, and drainage systems. They provide durable, slip-resistant surfaces while allowing water and debris to pass through. Their corrosion-resistant materials make them ideal for harsh weather conditions.

Q: How do large metal floor grates enhance safety in industrial settings?

A: Large metal floor grates offer sturdy support for heavy equipment and foot traffic in areas like factories or loading docks. Their open-grid design reduces tripping hazards and improves airflow. Anti-slip textures or coatings further boost safety in wet environments.

Q: What materials are best for durable metal floor grates in exterior environments?

A: Galvanized steel or stainless steel are top choices for exterior metal floor grates due to rust resistance. Aluminum grates are lightweight yet strong for moderate-use areas. Powder-coated finishes add extra protection against weathering and corrosion.

Q: How to choose the right size of metal floor grates for outdoor drainage?

A: Select grates based on expected water flow—larger openings handle heavy rainfall better. Ensure the grate size aligns with existing drainage system dimensions. Check load ratings to match vehicular or pedestrian traffic needs.

Q: Can metal floor grates be customized for unique exterior designs?

A: Yes, many manufacturers offer custom shapes, patterns, and finishes for metal floor grates. Options include decorative motifs for architectural projects or tailored dimensions for irregular spaces. Custom coatings can also match specific color schemes.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025