- Průmyslová zóna, jižně od města Anping, Hengshui, Hebei, Čína.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Angličtina

Angličtina  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Angličtina

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Perimeter Safety Netting: The Critical Safety Upgrade for Every Helipad

When it comes to aviation infrastructure, few components are as essential yet often overlooked as perimeter safety netting. Specially designed to ensure the protection of crew, passengers, and aircraft in the most extreme environments, helipad netting systems go far beyond the capabilities of standard safety net products. Whether installed on hospital rooftops, offshore oil platforms, or skyscrapers, these netting systems play a vital role in minimizing fall risks and improving overall operational safety.

Helipads Perimeter Safety Netting vs. Standard Safety Net: What’s the Difference?

While a typical safety net on a construction site is designed to catch falling debris or workers in vertical applications, the demands placed on helipads perimeter safety netting are far more rigorous. The most obvious difference lies in the application—helipads are elevated, wind-exposed platforms where aircraft land and take off under high-speed rotor wash and unpredictable weather conditions. Therefore, perimeter safety netting must withstand not only vertical force but lateral air thrust as well.

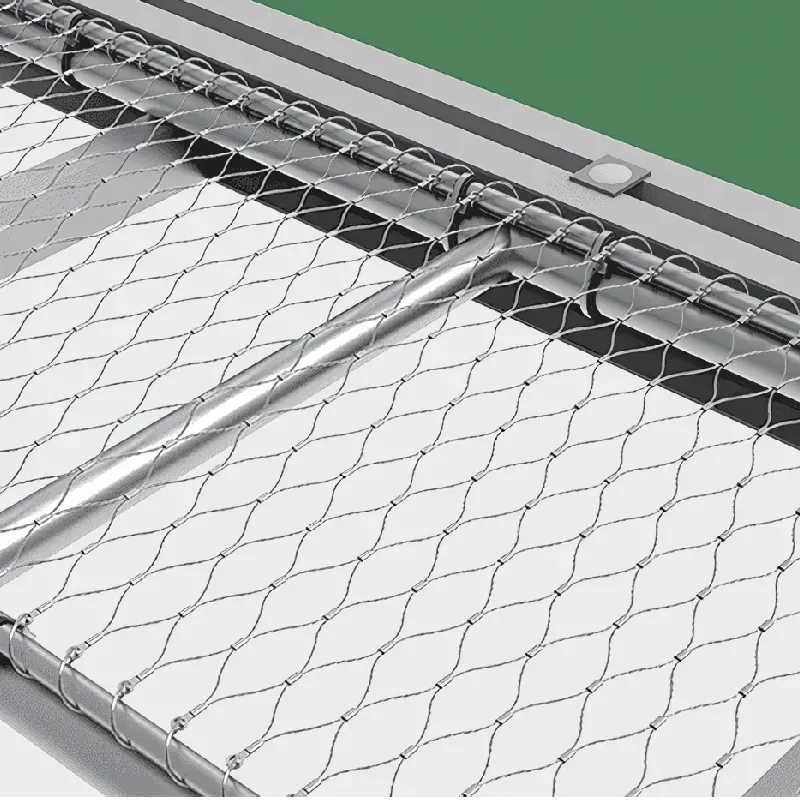

The structural design of stainless steel rope helipad perimeter safety netting includes tensioned frameworks, reinforced edging, and marine-grade components to endure these stresses. Unlike traditional nylon or polypropylene safety net materials, these high-tensile stainless-steel nets resist UV degradation, salt corrosion, and repeated mechanical stress. They are designed to provide a continuous, visible edge barrier, creating both a physical and psychological safety zone for ground personnel operating on the helideck.

Stainless Steel Rope Helipad Perimeter Safety Netting and Wind Load Resistance

One of the most demanding specifications for helipads perimeter safety netting is its ability to withstand extreme wind speeds. The International Civil Aviation Organization (ICAO) and CAP 437 guidelines require that perimeter netting systems remain stable under wind speeds up to 100 knots (approximately 185 km/h). This requirement takes into account rotor downwash from helicopters such as the Sikorsky S-92 or AW101, which can produce thrust equivalent to hurricane-force winds during landing and takeoff.

High-quality perimeter safety netting constructed with stainless steel rope and tensioned edge systems meets or exceeds this standard. In laboratory tests and real-world offshore environments, stainless steel rope helipad perimeter safety netting has proven capable of withstanding wind forces beyond 100 knots without deformation or detachment. The anchoring systems are usually custom-engineered based on the structure’s wind exposure category and are fatigue-tested for long-term resistance.

How Perimeter Safety Netting Color Affects Pilot Line of Sight on Helipads

Another often-overlooked factor in the design of helipads perimeter safety netting is color visibility. While performance under load is critical, visibility from the air is equally important to pilots during approach and landing. Bright, high-contrast edge netting improves the pilot’s ability to identify the landing perimeter, especially in low-light or adverse weather conditions.

Research shows that fluorescent yellow and red edge tapes or netting fibers improve recognition time by up to 25% compared to standard gray or black mesh. These colored nettings do not affect the performance of perimeter safety netting but enhance pilot orientation and landing accuracy. Many stainless steel rope helipad perimeter safety netting solutions now offer integrated lighting and reflective edging built into the net system, further increasing night-time and low-visibility usability.

The careful consideration of color, tension, and durability in helipads perimeter safety netting directly contributes to both visual navigation and passive safety—making it an indispensable element of modern helideck construction.

Custom Features of Safety Net Systems for Helipads

Modern perimeter safety netting does more than secure helipads—it can also be customized to enhance architectural aesthetics and comply with regional safety standards. Leading systems feature modular design, corrosion-resistant anchors, and tool-free removal for maintenance, while still offering the highest levels of strength and flexibility.

Additionally, stainless steel rope helipad perimeter safety netting is fully customizable in mesh size, shape, and layout. Designers can integrate it into new construction or retrofit it onto existing platforms. Advanced coatings like PVDF or marine-grade paints further extend the visual appeal and durability in challenging environments such as coastal helipads or offshore platforms.

Customers can also specify UV-protected top cording, seamless edge transitions, and aerodynamic flow-through designs to reduce wind drag while preserving full protection. The fusion of safety, functionality, and appearance makes helipads perimeter safety netting a smart investment for hospitals, energy platforms, and commercial high-rises alike.

Perimeter Safety Netting FAQs

What are the main differences between helipad and building safety netting?

Standard safety net systems are designed for vertical load protection in construction, while perimeter safety netting for helipads is engineered for lateral wind resistance, rotor wash, and elevated platform safety using stainless steel rope and reinforced framing.

What wind speed must helipad perimeter netting withstand?

According to international safety standards, helipads perimeter safety netting must endure wind speeds up to 100 knots, ensuring stability during helicopter landing and takeoff in severe weather and high-thrust conditions.

How does netting color impact pilot visibility?

Color plays a key role in visual orientation. Obvodová bezpečnostní síť with fluorescent or reflective edge detailing helps pilots quickly identify helipad boundaries, especially under poor visibility, reducing landing risks.

Why choose stainless steel rope helipad perimeter safety netting over synthetic options?

Stainless steel rope helipad perimeter safety netting offers superior corrosion resistance, UV stability, and mechanical strength compared to synthetic materials, making it ideal for harsh, exposed environments like offshore rigs or coastal helipads.

Can helipad perimeter netting be customized for different applications?

Yes, perimeter safety netting systems can be fully tailored in terms of mesh size, edge design, color, and installation method to suit new construction, retrofits, and various industry-specific requirements.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationZprávyAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyZprávyAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsZprávyAug.08,2025

-

Precision Strength with Welded Steel Bar GratingZprávyAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsZprávyAug.08,2025

-

Maximize Performance with Steel Walkway GratingZprávyAug.08,2025