- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Led . 20, 2025 15:39

Back to list

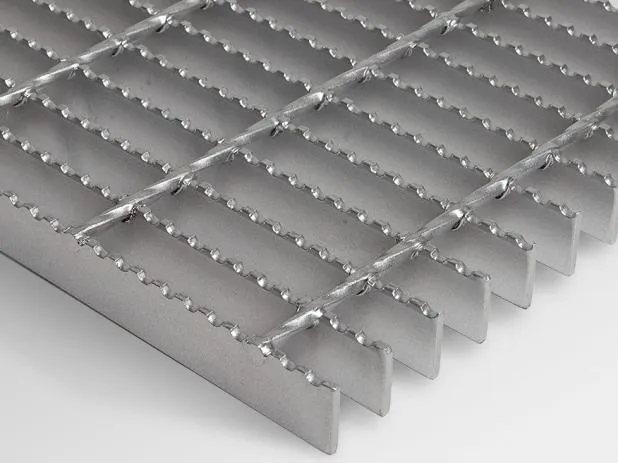

Welded Steel Grating

Aluminum bar grating weight plays a critical role in its selection and application across various industries. With unparalleled characteristics such as strength, durability, and corrosion resistance, aluminum bar gratings are a top choice in construction, industrial, and commercial projects. Here’s an in-depth analysis of the factors affecting the weight of aluminum bar grating, its implications, and why understanding these specifics can greatly benefit you in choosing the right grating for your needs.

To further delve into optimizing usage, consider custom fabrications. Aluminum bar gratings can be tailored in terms of bearing bar thickness, spacing, and cross-rod placement to suit detailed project criteria. A thicker bearing bar might increase weight marginally but offer enhanced load-bearing capacity. Engineering precision in these parameters can result in a grating that perfectly balances weight and performance, tailored specifically to the demands of your project. Safety standards also intertwine with the discussion about aluminum bar grating weight. Safety regulations often mandate specific load-bearing capacities for flooring in industrial settings. Choosing grating that meets these criteria while also being conscious of its weight can significantly impact compliance and safety outcomes. Lighter gratings frequently result in safer installation processes and lower potential for accidents during handling. Real-world examples illustrate the benefits well in a high-traffic pedestrian bridge renovation project, using lightweight but strong aluminum bar gratings allowed for rapid installation over a weekend shutdown, minimizing public disruption, and ensuring compliance with safety standards. Similarly, in offshore drilling rigs, the reduced weight of aluminum bar gratings plays a critical role in mitigating load on structural frameworks, leading to better longevity and reduced maintenance costs. In conclusion, paying close attention to the aluminum bar grating weight can provide significant operational advantages, from design flexibility and installation efficiency to enhanced safety and compliance. Understanding this crucial attribute, informed by expertise and real-world empirical data, will inevitably lead you to make more authoritative and trustworthy decisions. With the correct selection, aluminum bar grating will not only meet your immediate functional expectations but also support long-term structural goals with its resilient and adaptable nature.

To further delve into optimizing usage, consider custom fabrications. Aluminum bar gratings can be tailored in terms of bearing bar thickness, spacing, and cross-rod placement to suit detailed project criteria. A thicker bearing bar might increase weight marginally but offer enhanced load-bearing capacity. Engineering precision in these parameters can result in a grating that perfectly balances weight and performance, tailored specifically to the demands of your project. Safety standards also intertwine with the discussion about aluminum bar grating weight. Safety regulations often mandate specific load-bearing capacities for flooring in industrial settings. Choosing grating that meets these criteria while also being conscious of its weight can significantly impact compliance and safety outcomes. Lighter gratings frequently result in safer installation processes and lower potential for accidents during handling. Real-world examples illustrate the benefits well in a high-traffic pedestrian bridge renovation project, using lightweight but strong aluminum bar gratings allowed for rapid installation over a weekend shutdown, minimizing public disruption, and ensuring compliance with safety standards. Similarly, in offshore drilling rigs, the reduced weight of aluminum bar gratings plays a critical role in mitigating load on structural frameworks, leading to better longevity and reduced maintenance costs. In conclusion, paying close attention to the aluminum bar grating weight can provide significant operational advantages, from design flexibility and installation efficiency to enhanced safety and compliance. Understanding this crucial attribute, informed by expertise and real-world empirical data, will inevitably lead you to make more authoritative and trustworthy decisions. With the correct selection, aluminum bar grating will not only meet your immediate functional expectations but also support long-term structural goals with its resilient and adaptable nature.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025