- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 08, 2025 01:44

Back to list

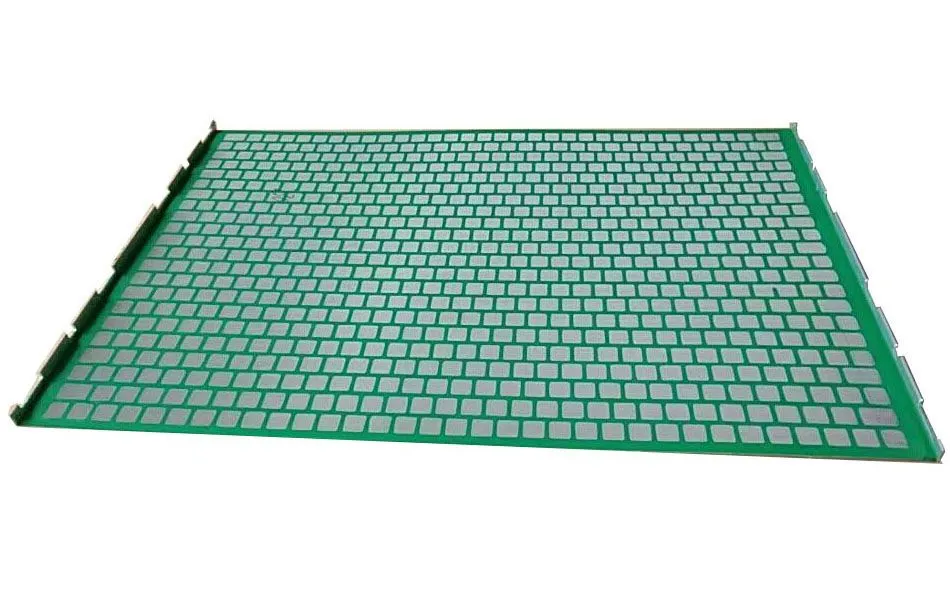

press-locked steel grating

Press-locked steel grating is rapidly becoming a preferred choice for industries seeking robust, safe, and durable flooring solutions. Used extensively in sectors like petrochemicals, mining, and transportation, this type of grating is known for its unique combination of strength, precision, and resilience, thanks to the advanced manufacturing processes involved.

Furthermore, press-locked steel grating is celebrated for its low maintenance demands. Its design inherently resists accumulations of debris, facilitating easy cleaning and minimizing upkeep efforts. This endurance against harsh weather conditions and chemical exposures without significant wear or corrosion illustrates its reliability, reinforcing trust from industry professionals globally. Another noteworthy aspect is its environmental advantage. Often manufactured from recycled materials and fully recyclable itself, press-locked steel grating aligns with sustainable development goals. Industries increasingly prioritize eco-friendly practices, and the incorporation of sustainable materials in their infrastructure further validates their commitment to environmental responsibility. To leverage the full benefits of press-locked steel grating, it's critical to partner with reputable manufacturers known for adhering to stringent quality standards. By doing so, businesses not only gain from an exemplary product but also ensure compliance with relevant safety and structural regulations, fostering a trustworthy operational environment. For decision-makers considering press-locked steel grating, understanding these facets provides assurance that this is a product not merely born from expertise but backed by credible engineering insights and extensive application experience. Such reliable performance and adaptability make press-locked steel grating an optimal, forward-thinking choice for modern industrial needs.

Furthermore, press-locked steel grating is celebrated for its low maintenance demands. Its design inherently resists accumulations of debris, facilitating easy cleaning and minimizing upkeep efforts. This endurance against harsh weather conditions and chemical exposures without significant wear or corrosion illustrates its reliability, reinforcing trust from industry professionals globally. Another noteworthy aspect is its environmental advantage. Often manufactured from recycled materials and fully recyclable itself, press-locked steel grating aligns with sustainable development goals. Industries increasingly prioritize eco-friendly practices, and the incorporation of sustainable materials in their infrastructure further validates their commitment to environmental responsibility. To leverage the full benefits of press-locked steel grating, it's critical to partner with reputable manufacturers known for adhering to stringent quality standards. By doing so, businesses not only gain from an exemplary product but also ensure compliance with relevant safety and structural regulations, fostering a trustworthy operational environment. For decision-makers considering press-locked steel grating, understanding these facets provides assurance that this is a product not merely born from expertise but backed by credible engineering insights and extensive application experience. Such reliable performance and adaptability make press-locked steel grating an optimal, forward-thinking choice for modern industrial needs.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025