- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

galvanized serrated grating

Understanding Galvanized Serrated Grating Features, Benefits, and Applications

Galvanized serrated grating has become a popular choice in various industrial applications due to its unique design, durability, and safety features. This article explores what galvanized serrated grating is, its benefits, and where it is typically used.

What is Galvanized Serrated Grating?

Galvanized serrated grating is a type of metal grating that undergoes a galvanization process to enhance its corrosion resistance and overall durability. The term serrated refers to the unique surface profile of the grating, which features a series of ridges or serrations. This design increases slip resistance, making it especially suitable for environments where safety is a concern, such as slippery or wet surfaces.

The grating is usually made from steel, stainless steel, or aluminum, which are then hot-dipped in zinc to create a protective layer. This galvanization process not only improves the lifespan of the grating by preventing rust and corrosion but also enhances its aesthetic appeal, offering a shiny, metallic finish that blends well in various environments.

Benefits of Galvanized Serrated Grating

1. Enhanced Safety One of the most significant advantages of serrated grating is its non-slip surface. The ridges created by the serration provide better traction, which is vital in preventing accidents in high-traffic areas, especially in industries such as oil and gas, food processing, and wastewater treatment.

2. Corrosion Resistance The galvanization process protects the grating from corrosion, which is crucial in environments exposed to moisture or chemicals. This property significantly increases the lifespan of the grating, making it a cost-effective choice for long-term applications.

3. Lightweight Yet Strong Despite being robust and durable, galvanized serrated grating is relatively lightweight compared to solid metal plates. This characteristic makes it easier to handle and install, reducing labor costs and time during the installation process.

4. Versatility Galvanized serrated grating is available in various sizes, thicknesses, and configurations, making it suitable for a wide range of applications. Whether used for walkways, platforms, or drainage covers, its versatility ensures that it meets specific project requirements.

galvanized serrated grating

5. Low Maintenance The protective layer provided by galvanization means that once installed, the grating requires minimal maintenance. This benefit is particularly advantageous for companies looking to reduce operational costs and improve efficiency.

Applications of Galvanized Serrated Grating

The applications of galvanized serrated grating span multiple industries, owing to its strength, safety features, and resistance to environmental factors.

1. Industrial Facilities This type of grating is commonly used in factories and plants, providing safe walkways, stair treads, and work platforms that withstand heavy foot and vehicular traffic.

2. Transport and Infrastructure Galvanized serrated grating is frequently found in bridges, parking garages, and public transportation systems, where durability and safety are paramount.

3. Water Management In wastewater treatment facilities, the grating can be used for walkways and covers over drainage systems, where it effectively prevents slips and provides safe access.

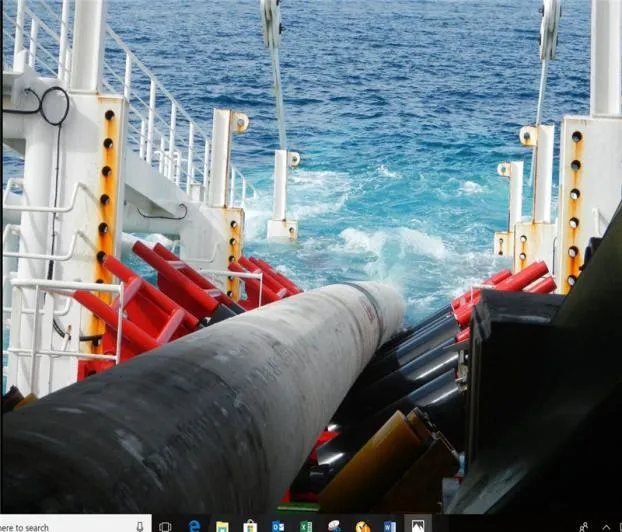

4. Marine Applications The corrosion resistance of galvanized materials makes serrated grating a favored choice in marine environments, such as docks and piers, where exposure to saltwater can quickly deteriorate other materials.

5. Food Processing The non-slip nature of the serrated surface is ideal for food processing plants, where wet conditions are common. It helps maintain safety while complying with hygiene standards.

Conclusion

In summary, galvanized serrated grating stands out as an essential component in various industrial and commercial applications. Its combination of slip resistance, durability, and low maintenance makes it an attractive solution for businesses looking to enhance safety and efficiency. As industries continue to prioritize these attributes, the popularity of galvanized serrated grating is expected to grow, further solidifying its role in modern infrastructure and manufacturing.

-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025