- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 14, 2025 11:24

Back to list

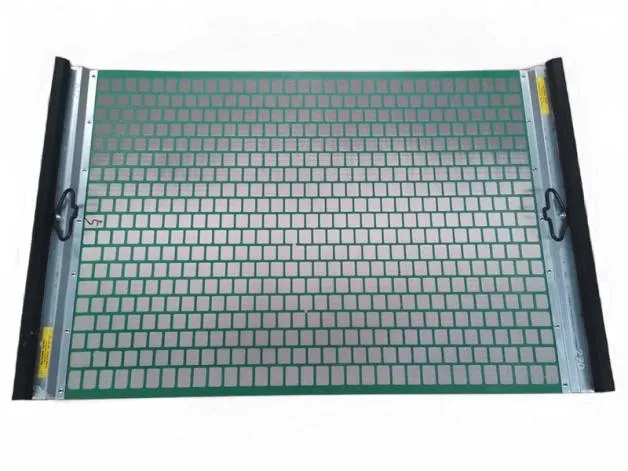

shale screen

Shale screen technology has revolutionized the oil and gas industry, offering unprecedented efficiency and precision in drilling operations. As an essential component in the separation and filtration processes, shale screens are designed to optimize the extraction of hydrocarbons while minimizing environmental impact and operational costs. This article delves into the unique benefits and considerations involved in selecting the right shale screen for your projects, drawing on real-world expertise and authoritative research to provide trustworthy guidance.

Authoritative insight from industry leaders indicates that continuous maintenance and performance monitoring are crucial for maximizing the lifespan and efficiency of shale screens. Regular checks and balances should be implemented to ensure that screens are functioning at peak capacity. Sensors and automated systems can provide real-time data analysis, allowing operators to make informed decisions promptly, thus enhancing operational trustworthiness. The reliability of shale screens is underscored by independent verification and certifications that assure compliance with industry standards. Such endorsements offer an additional layer of confidence for operators, validating the performance claims made by manufacturers and reinforcing the credibility of their products. Partnering with established brands known for their rigorous testing and quality assurance can further solidify trust in your shale screen selections. In conclusion, the incorporation of appropriately selected and maintained shale screens in drilling operations represents an invaluable investment in both economic and environmental terms. By prioritizing experience-backed expertise and robust product offerings validated by authoritative sources, operators can ensure the trustworthiness and efficiency of their drilling processes. Emphasizing these factors can yield substantial improvements in operational outcomes, establishing a competitive advantage in a demanding industry landscape.

Authoritative insight from industry leaders indicates that continuous maintenance and performance monitoring are crucial for maximizing the lifespan and efficiency of shale screens. Regular checks and balances should be implemented to ensure that screens are functioning at peak capacity. Sensors and automated systems can provide real-time data analysis, allowing operators to make informed decisions promptly, thus enhancing operational trustworthiness. The reliability of shale screens is underscored by independent verification and certifications that assure compliance with industry standards. Such endorsements offer an additional layer of confidence for operators, validating the performance claims made by manufacturers and reinforcing the credibility of their products. Partnering with established brands known for their rigorous testing and quality assurance can further solidify trust in your shale screen selections. In conclusion, the incorporation of appropriately selected and maintained shale screens in drilling operations represents an invaluable investment in both economic and environmental terms. By prioritizing experience-backed expertise and robust product offerings validated by authoritative sources, operators can ensure the trustworthiness and efficiency of their drilling processes. Emphasizing these factors can yield substantial improvements in operational outcomes, establishing a competitive advantage in a demanding industry landscape.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025